Perovskite thin film, precursor composition thereof, preparation method and semiconductor element

A composition, perovskite technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, oxide/hydroxide preparation, etc., can solve the problem of high surface roughness, affecting component performance, and difficult to precisely control the uniformity of film formation And film quality and other issues, to achieve the effect of large lattice arrangement, reduced impurities, high component efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] In the process flow of the preparation method disclosed in the present disclosure, the coating method in the coating step includes slit coating, doctor blade coating, air knife coating or inkjet coating.

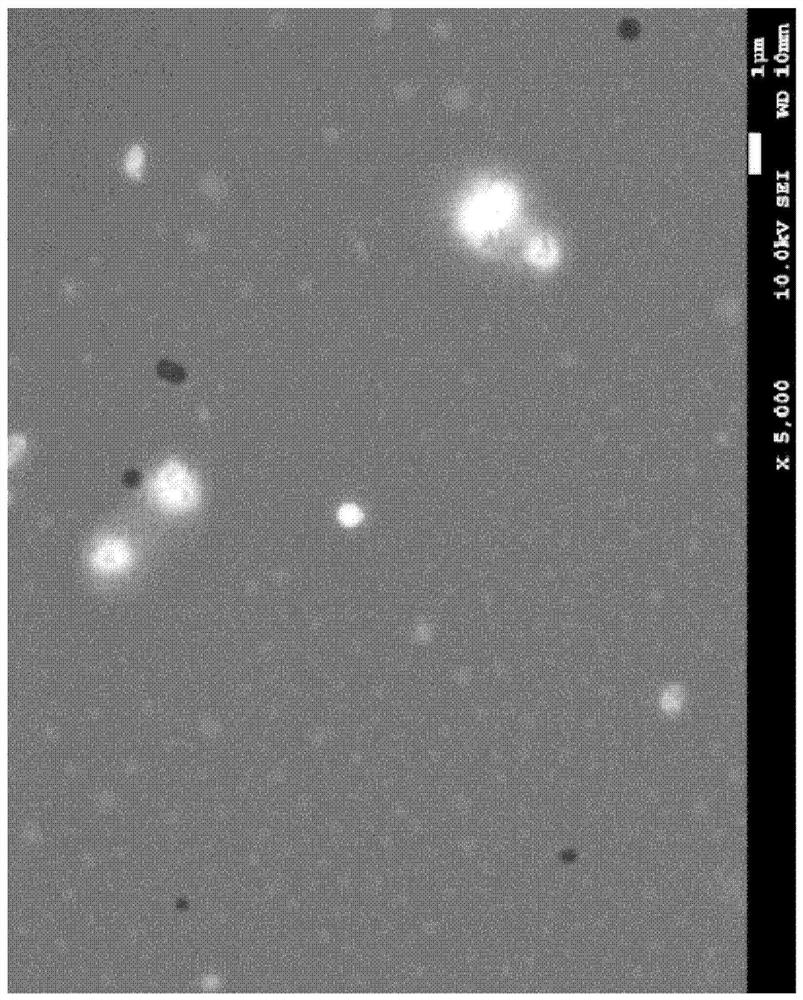

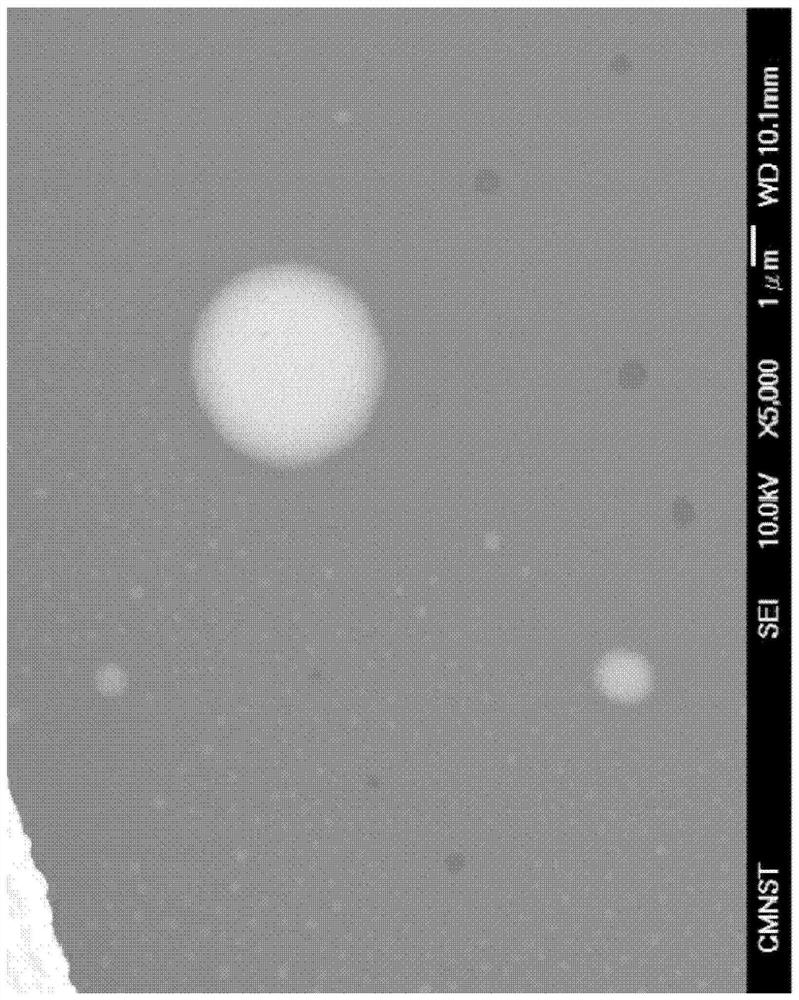

[0065] The doctor blade coating is suitable for industrial-scale production, and its film-forming principle is to make nucleation and crystal growth proceed simultaneously by controlling the solvent evaporation rate at high temperature. Therefore, the perovskite film produced by the present disclosure also has a larger grain size and a smoother film surface than those produced by other processes.

[0066] In a specific embodiment, the operating temperature of the knife coating is 130 to 180° C., and the speed of the knife coating is 1 to 50 mm / s; in other embodiments, the operating temperature of the knife coating can be 140, 150, 160 or 170°C, but not limited thereto.

[0067] The preparation method of the perovskite thin film of the present disclosure may further i...

Embodiment 1-1

[0114] Preparation of the precursor composition: γ-butyrolactone and dimethyl sulfoxide are used as the mixed solvent of the precursor composition; the perovskite precursor salt of the precursor composition includes formamidine hydroiodide (FAI), lead bromide (PbBr 2 ), methylamine hydrobromide (MABr), lead iodide (PbI 2 ), cesium iodide (CsI).

[0115] First, formamidine hydroiodide (FAI), lead bromide (PbBr 2 ), methylamine hydrobromide (MABr), lead iodide (PbI 2 ), cesium iodide (CsI) and other perovskite precursor salts are sequentially dispersed or dissolved to form the first solution, wherein the volume molar concentration of the formamidine hydriodide is 0.159M, and the volume molar concentration of the lead bromide is 0.159M, the volume molar concentration of the methylamine hydrobromide is 0.159M, the volume molar concentration of the lead iodide is 0.9M and the volume molar concentration of the cesium iodide is 1.35M; the gamma-butyrolactone and di The volume rat...

Embodiment 1-2 to 1-3

[0126] Examples 1-2 to 1-3: Preparation of perovskite thin films

[0127] The preparation method of its perovskite film is the same as that of Example 1-1, when the volume molar concentration of 18-crown-6 in its precursor composition is changed to 0.25mM and 0.45mM respectively; The surface observation and crystallinity analysis of the titanium ore thin film were carried out and recorded in image 3 , Figure 4 , Figure 5B , Figure 5C , Figure 6A and Figure 6B .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com