Composite material sheet for microwave circuit substrate, preparation method of composite material sheet and microwave circuit substrate

A technology for circuit substrates and composite materials, applied in circuit substrate materials, printed circuits, printed circuit components, etc., can solve the problems of high water absorption and difficult processing technology, and achieve the effect of increasing molding performance and reducing processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

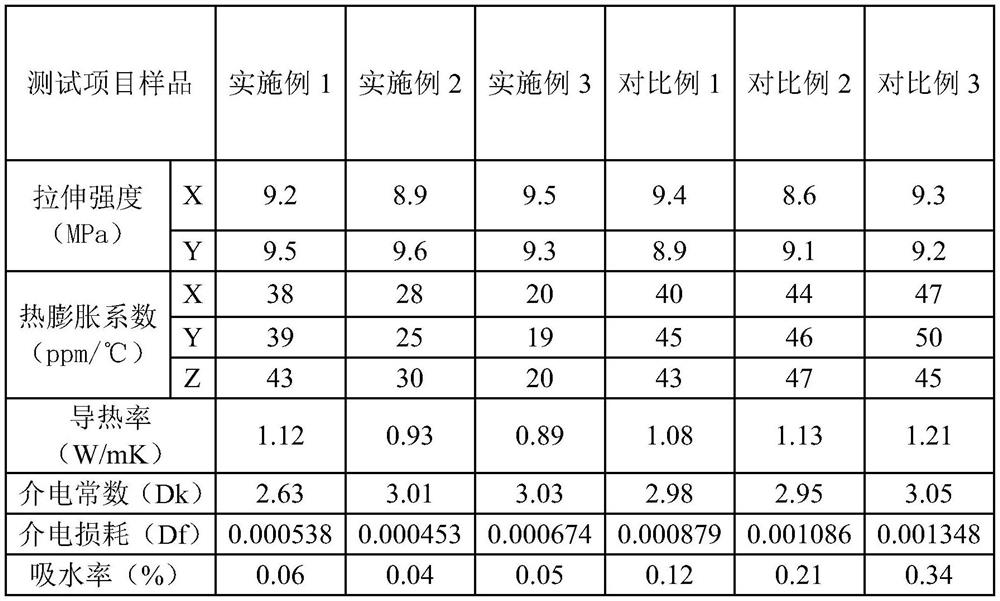

Examples

Embodiment 1

[0040] This embodiment provides a specific circuit substrate preparation method, including the following steps:

[0041] 1) Weigh 10 kg of PTFE dispersion material and 3 kg of modified silicon dioxide, and mix them for 1 hour with a high-speed blender at a speed of 600 rpm to obtain a uniformly mixed blend.

[0042] 2) Pass the above-mentioned blended material through 40-mesh and 70-mesh sieves respectively, then add kerosene, the amount of kerosene added is 30wt% of the total mass of the blended material, mix well and then mature at 90°C for 1h.

[0043] 3) Put the matured blend into a press to make a round billet, press at 10 MPa, keep the pressure for 5 min, and temperature 70° C. to obtain a cylindrical billet with a length of 100 mm and a diameter of 60 mm.

[0044] 4) Put the above-mentioned cylindrical blank into an extruder, extrude with a pressure of 10 MPa and a die opening width of 150 mm, and finally obtain a sheet with a width of 150 mm and a thickness of 5 mm.

...

Embodiment 2

[0048] This embodiment provides a specific circuit substrate preparation method, including the following steps:

[0049] 1) Weigh 10kg of PTFE dispersion material, 11kg of modified silica, and 1.4kg of composite ceramic powder at a speed of 600rpm, and mix them with a high-speed blender for 1 hour at a speed of 600rpm to obtain a uniformly mixed blend.

[0050] 2) Pass the above-mentioned blended materials through 40 mesh and 70 mesh screens respectively, then add isoparaffin solvent oil, the addition of the isoparaffin solvent oil is 30wt% of the total mass of the blend material, after mixing uniformly Mature at 90°C for 1h.

[0051] 3) Put the cured blend into a press to make a cylindrical billet, press at 15 MPa, keep the pressure for 5 minutes, and temperature 70° C. to obtain a cylindrical billet with a length of 100 mm and a diameter of 60 mm.

[0052] 4) Put the above-mentioned cylindrical blank into an extruder, extrude with a pressure of 15Mpa and a die width of 150mm,...

Embodiment 3

[0056] This embodiment provides a specific circuit substrate preparation method, including the following steps:

[0057] 1) Weigh 10kg of PTFE dispersion material, 11kg of modified silica, and 1.4kg of composite ceramic powder at a speed of 600rpm, and mix them with a high-speed blender for 1 hour at a speed of 600rpm to obtain a uniformly mixed blend.

[0058] 2) Pass the above blended materials through 40 mesh and 70 mesh screens respectively, then add isoparaffin solvent oil, the addition amount of the isoparaffin solvent oil is 30wt% of the blend material mass, mix evenly and mature at 90°C 1h.

[0059] 3) Put the matured blend into a press to make a round billet, press at 15 MPa, keep the pressure for 5 min, and temperature 70° C. to obtain a cylindrical billet with a length of 100 mm and a diameter of 60 mm.

[0060] 4) Put the above-mentioned cylindrical blank into an extruder, extrude with a pressure of 15Mpa and a die width of 150mm to obtain a sheet with a width of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com