A kind of high-density, controllable composition of high-silicon aluminum alloy material and preparation method

A high-silicon aluminum alloy and dense technology, applied in the field of alloy processing, can solve the problems of reducing strength, plasticity and wear resistance, deteriorating cutting performance, and difficult to form metallurgical bonding, etc., to improve strength and elastic modulus, improve The final density and the effect of increasing the bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of a high-density, controllable high-silicon aluminum alloy material, comprising the following steps: comprising the following steps: 10 AlMgSi was prepared by multi-stage hot pressing sintering after mixing alloy powder and silicon powder X Alloys where X is greater than 10.

[0024] In some embodiments of the present invention, a method for preparing a high-density, composition-controllable high-silicon aluminum alloy material includes the following steps:

[0025] AlMgSi 10 Alloy powder and silicon powder are mixed in proportion to obtain mixed powder;

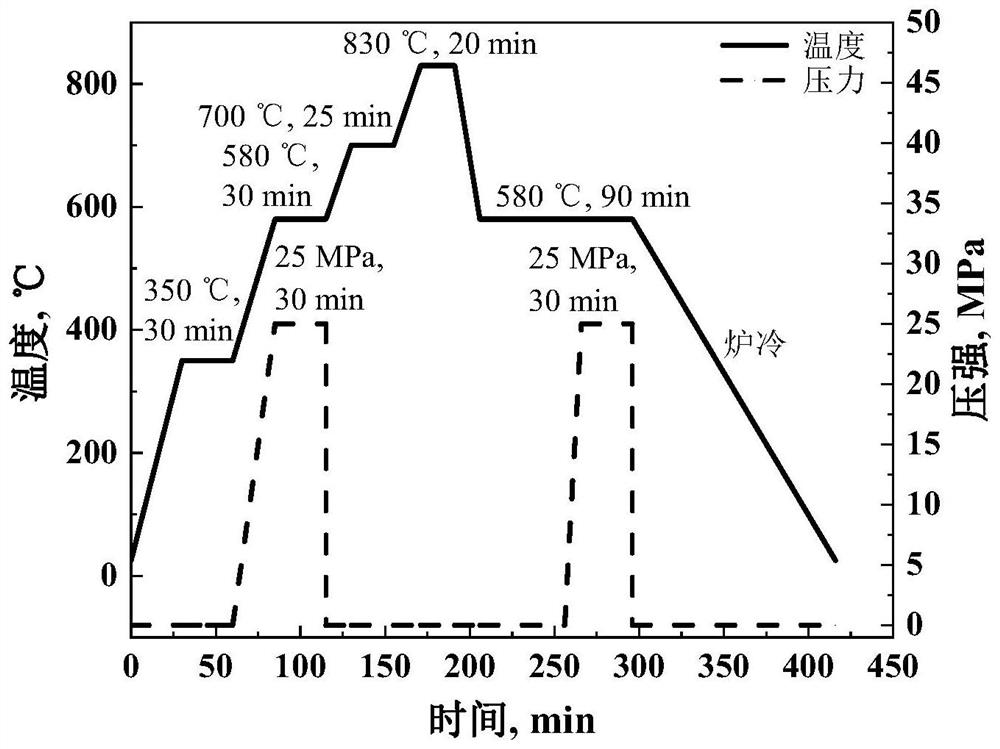

[0026] The mixed powder is subjected to multi-stage hot-pressing sintering: the parameters of the multi-stage hot-pressing sintering are: the first stage: sintering at 350° C. and 0 MPa for 30 minutes; the second stage: sintering at 580° C. and 25 MPa for 30 minutes; The third stage: sintering at 10°C higher than the liquidus temperature and 0MPa for no more than 30min; the fourth stage: sinte...

Embodiment 1

[0039] AlMgSi10 alloy powder is used as the matrix, and Si powder is added. The mixed powder is uniformly mixed by planetary ball milling. The mass fraction of Si in the designed alloy is 20wt.%, and a multi-stage hot pressing sintering process is adopted; the parameters of the multi-stage hot pressing sintering are: The first stage: sintering at 350℃ and 0MPa for 30min; the second stage: sintering at 580℃ and 25MPa for 30min; the third stage: sintering at 10℃ above the liquidus temperature and 0MPa for no more than 30min; the fourth stage : Sintering at 580℃ and 25MPa for 30min. AlMgSi20 alloy was obtained, the density of the alloy was as high as 99.86%, the compressive strength was 270.9MPa, the elastic modulus was 88.33GPa, and the thermal expansion coefficient was 17.2×10 -6 K -1 , the thermal conductivity is 186.4W / (m×K).

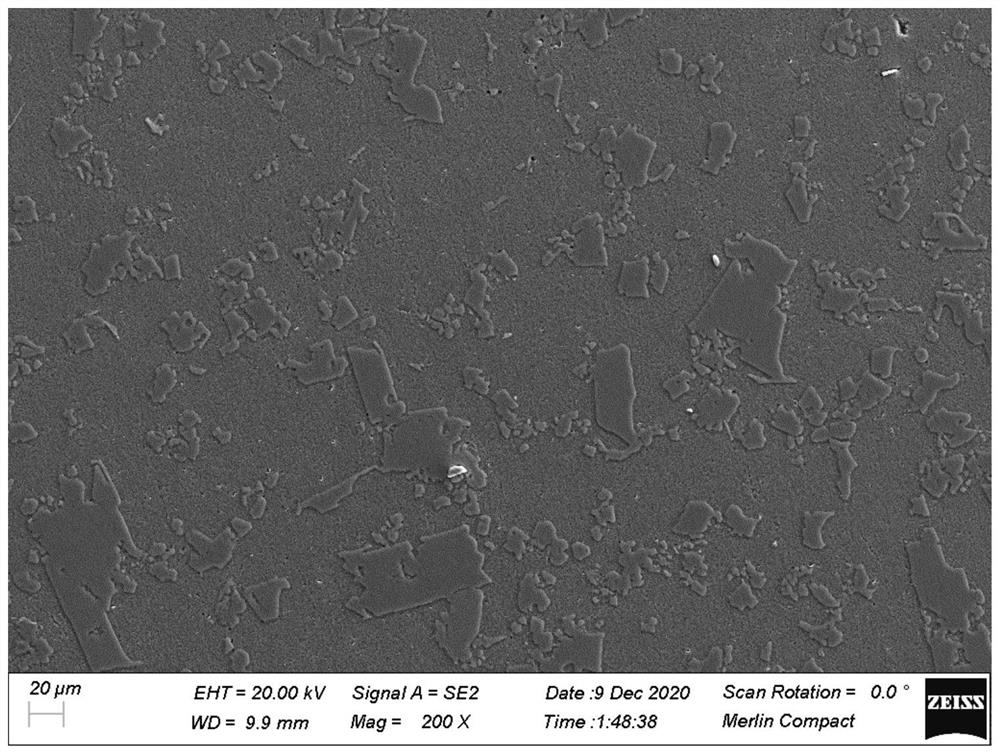

[0040] figure 2 It is the corresponding scan image of Example 1. It can be observed from the figure that the primary crystal silicon grains are s...

Embodiment 2

[0042] combined with figure 1 , using AlMgSi10 alloy powder as the matrix, plus Si powder, the mixed powder is mixed evenly by planetary ball milling, the mass fraction of Si in the design alloy is 30wt. figure 1 shown); to obtain AlMgSi30 alloy, the density of the alloy is 98.06%, the compressive strength is 227.8MPa, the elastic modulus is 95.83GPa, and the thermal expansion coefficient is 14.9×10 -6 K -1 , the thermal conductivity is 152.3W / (m×K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com