Preparation method of ultrahigh water-soluble chlortetracycline hydrochloride

A chlortetracycline hydrochloride, water-soluble technology, applied in the field of preparation of ultra-high water-soluble chlortetracycline hydrochloride, can solve the problems of increased impurity content, poor long-term stability, easy discoloration, etc., and achieves increased contact area and increased Biological activity, the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

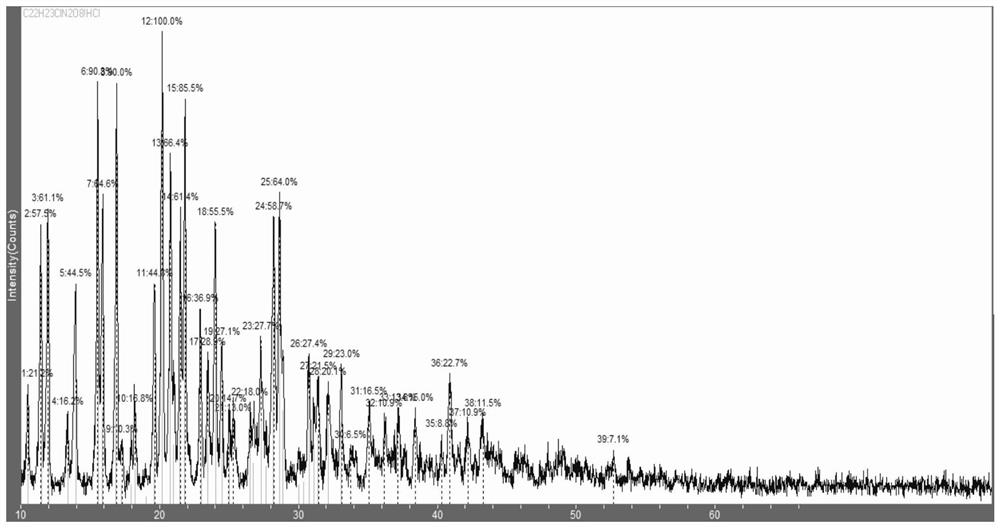

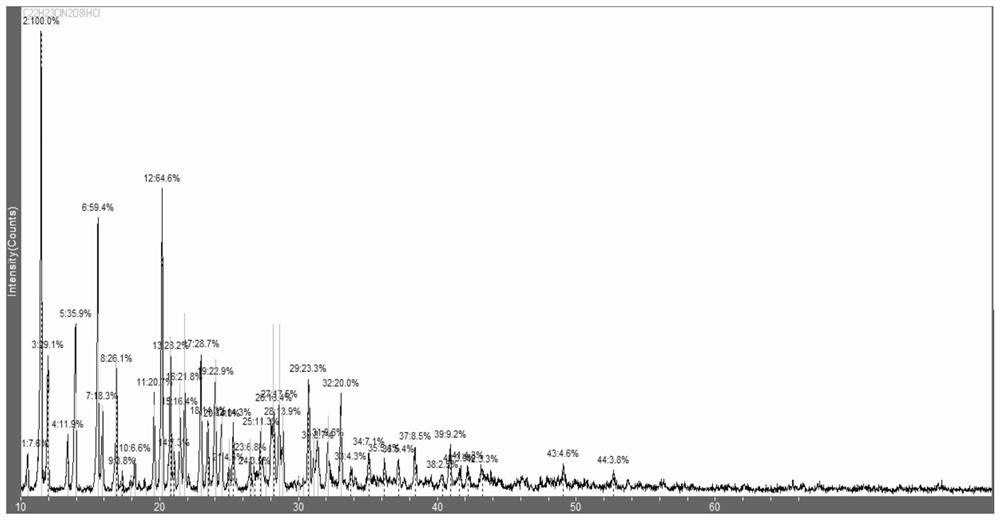

Image

Examples

Embodiment 1

[0059] The preparation method of ultrahigh water-soluble aureomycin hydrochloride comprises the steps:

[0060] 1) Acidification of fermentation broth:

[0061] Cool the chlortetracycline fermentation broth to 2°C, and add purified water equivalent to 1.0 times the volume of the chlortetracycline fermentation broth;

[0062] Then add oxalic acid at a ratio of 2.0 g per 100 mL of aureomycin fermentation broth, and adjust the pH to 1.3 with hydrochloric acid;

[0063] Then add yellow blood salt sodium in a ratio of 0.15g per 100mL aureomycin fermentation broth, and stir for 25min;

[0064] Then add zinc sulfate at a ratio of 0.2 g per 100 mL of aureomycin fermentation broth, and stir for 25 min;

[0065] The obtained acidified solution is subjected to plate and frame pressure filtration, the filtrate is collected, the mycelia residue is washed with acid water having a pH of 1.5, the filtrate and the lotion are combined, the plate and frame re-filtration is performed, and the r...

Embodiment 2

[0083] The preparation method of ultrahigh water-soluble aureomycin hydrochloride comprises the steps:

[0084] 1) Acidification of fermentation broth:

[0085] Cool the chlortetracycline fermentation broth to 0°C, and add purified water equivalent to 1.2 times the volume of the chlortetracycline fermentation broth;

[0086] Then add oxalic acid at a rate of 1.5 g per 100 mL of aureomycin fermentation broth, and adjust the pH to 1.4 with hydrochloric acid;

[0087] Add yellow blood salt sodium at a ratio of 0.1 g per 100 mL of aureomycin fermentation liquid, and stir for 20 min;

[0088] Then add zinc sulfate at a ratio of 0.1 g per 100 mL of aureomycin fermentation broth, and stir for 20 min;

[0089] The obtained acidified solution is subjected to plate and frame pressure filtration, the filtrate is collected, the mycelia residue is washed with acid water having a pH of 1.5, the filtrate and the lotion are combined, the plate and frame re-filtration is performed, and the r...

Embodiment 3

[0107] The preparation method of ultrahigh water-soluble aureomycin hydrochloride comprises the steps:

[0108] 1) Acidification of fermentation broth:

[0109] Cool the chlortetracycline fermentation broth to 5°C, and add purified water equivalent to 0.5 times the volume of the chlortetracycline fermentation broth;

[0110]Then add oxalic acid at a ratio of 2.5 g per 100 mL of aureomycin fermentation liquid, and adjust the pH to 1.2 with hydrochloric acid;

[0111] Then add yellow blood salt sodium in a ratio of 0.2 g per 100 mL of aureomycin fermentation broth, and stir for 30 min;

[0112] Then add zinc sulfate at a rate of 0.3 g per 100 mL of aureomycin fermentation broth, and stir for 30 min;

[0113] The obtained acidified solution is subjected to plate and frame pressure filtration, the filtrate is collected, the mycelia residue is washed with acid water having a pH of 1.5, the filtrate and the lotion are combined, the plate and frame re-filtration is performed, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Solubility | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com