Preparation method of enhanced fly ash grinding aid

A technology of fly ash and grinding aid, which is applied in the field of preparation of enhanced fly ash grinding aid, can solve the problems of reduced building strength, insufficient performance of clinker, difference in wear resistance, etc. Compressive and flexural strength, uncomplicated production and processing technology, and simple production and processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

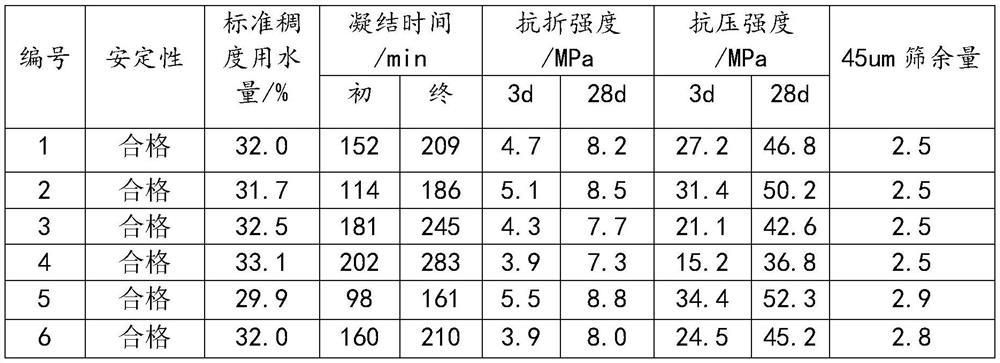

Examples

Embodiment 1

[0020] Embodiment 1: a kind of preparation method of enhanced fly ash grinding aid is specifically as follows:

[0021] (1) Using concentrated sulfuric acid as a catalyst, mix triethanolamine and glacial acetic acid in a 1:1 molar ratio in a distillation flask, and react at a temperature of 130-140° C. for 6-8 hours;

[0022] (2) reclaim dehydrating agent and unreacted raw material by vacuum distillation, finally obtain A additive;

[0023] (3) Put 20 parts of 20-mesh fly ash into the ultrasonic mixer, and add 40 parts of Ca(OH) into the ultrasonic mixer 2 and 35 parts of CaCO 3 ;

[0024] (4) Adjust the ultrasonic mixer to keep the ultrasonic mixer at a frequency of 20-40KHz, stir at a temperature of 20-30°C for 3 hours, and dry to obtain the B additive;

[0025] (5) Mix 5 parts of additive A, 30 parts of additive B, 5 parts of gypsum and 5 parts of limestone, and stir to obtain enhanced fly ash grinding aid.

Embodiment 2

[0027] (1) Using concentrated sulfuric acid as a catalyst, mix triethanolamine and glacial acetic acid in a 1:1 molar ratio in a distillation flask, and react at a temperature of 130-140° C. for 6-8 hours;

[0028] (2) reclaim dehydrating agent and unreacted raw material by vacuum distillation, finally obtain A additive;

[0029] (3) Put 20 parts of 20-mesh fly ash into the ultrasonic mixer, and add 40 parts of Ca(OH) into the ultrasonic mixer 2 and 35 parts of CaCO 3 ;

[0030] (4) Adjust the ultrasonic mixer to keep the ultrasonic mixer at a frequency of 20-40KHz, stir at a temperature of 20-30°C for 3 hours, and dry to obtain the B additive;

[0031] (5) Mix 5 parts of additive A, 20 parts of additive B, 5 parts of gypsum and 5 parts of limestone, and stir to obtain a fly ash grinding aid.

Embodiment 3

[0033] (1) Using concentrated sulfuric acid as a catalyst, mix triethanolamine and glacial acetic acid in a 1:1 molar ratio in a distillation flask, and react at a temperature of 130-140° C. for 6-8 hours;

[0034] (2) reclaim dehydrating agent and unreacted raw material by vacuum distillation, finally obtain A additive;

[0035] (3) Put 20 parts of 20-mesh fly ash into the ultrasonic mixer, and add 40 parts of Ca(OH) into the ultrasonic mixer 2 and 35 parts of CaCO 3 ;

[0036] (4) Adjust the ultrasonic mixer to keep the ultrasonic mixer at a frequency of 20-40KHz, stir at a temperature of 20-30°C for 3 hours, and dry to obtain the B additive;

[0037] (5) Mix 5 parts of additive A, 40 parts of additive B, 5 parts of gypsum and 5 parts of limestone, and stir to obtain a fly ash grinding aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com