Method for improving biological friction and corrosion resistance of titanium alloy surface

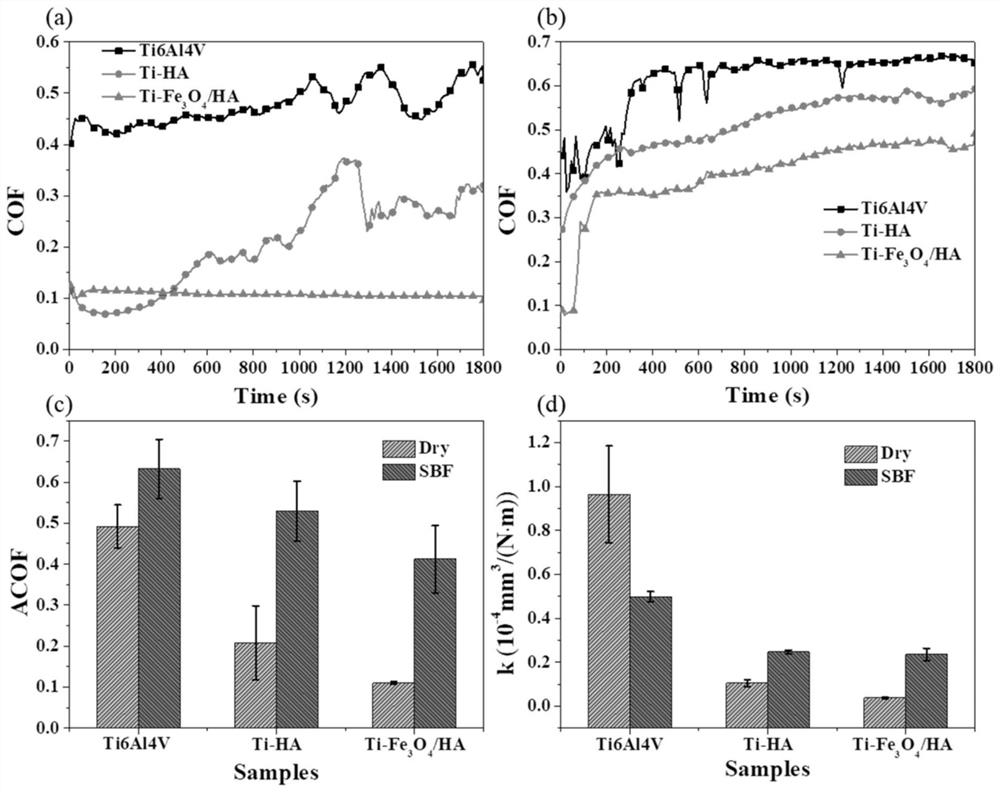

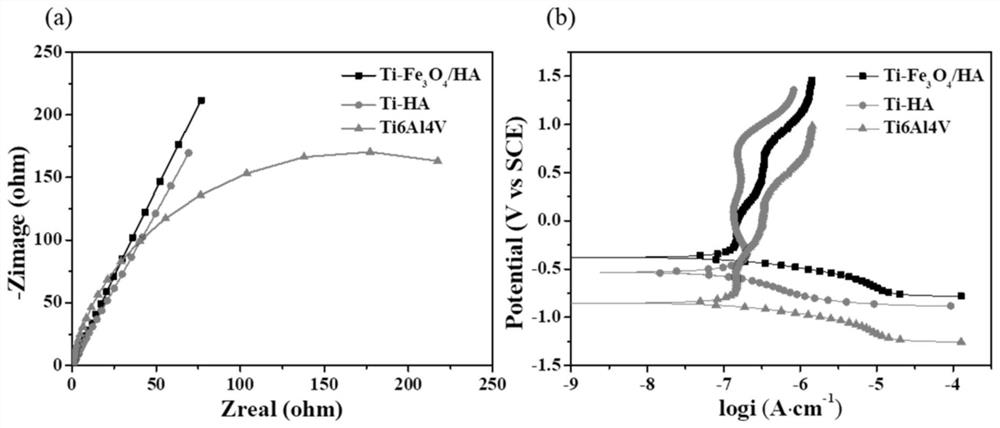

A corrosion-resistant, titanium alloy technology, applied in the direction of tissue regeneration, metal material coating process, coating, etc., can solve the problems of unverified wear resistance and corrosion resistance, and achieve simple and feasible construction method, microhardness Increased, improved effect of biotribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

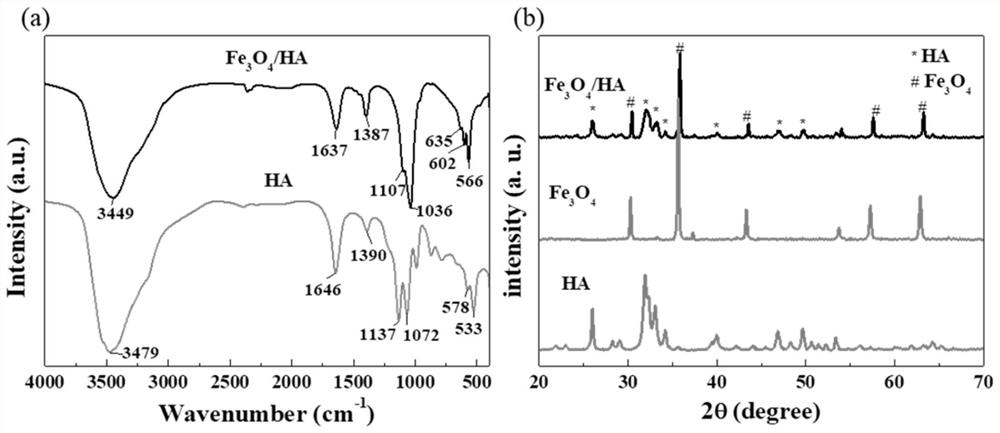

[0046] This embodiment selects Ti-Ni-Fe ternary alloy to provide Ti-Ni-Fe surface Fe 3 o 4 / HA coating composite coating and its preparation method are used to improve the corrosion resistance and biotribological properties of its surface. The preparation method comprises the following steps:

[0047] Polish Ti-Ni-Fe to a surface roughness of 0.5 μm, wash three times with acetone and deionized water, blow dry with nitrogen, soak in 2mol / L KOH solution for 24h; then put it into 3% silane coupling The reagent solution was reacted for 2 h to assemble the silane film.

[0048] After the sample obtained above was washed with water, it was placed in a 2 g / L dopamine solution to react for 12 hours, and a polydopamine adhesion layer was assembled on the surface. Then take it out and clean it for later use.

[0049] Weigh 0.37g of ferrous chloride and 1g of ferric chloride and dissolve them in 30mL of deionized water, then add 50mL of ammonia water (concentration is 25%), place in ...

Embodiment 2

[0055] The medical titanium alloy plate used in this embodiment is the raw material Ti6Al4V alloy of a certain medical equipment company, and the used Fe 3 o 4 The / HA coating was made in the laboratory. The preparation method comprises the following steps:

[0056] Polish the surface of the Ti6Al4V alloy to a roughness of 0.1 μm, wash it several times with deionized water, soak it in a 10mol / L NaOH solution for 6 hours; then put it into a 1wt% silane coupling agent aqueous solution to assemble the silane adhesion layer, Time 6h. After drying the surface with nitrogen, put it into 5g / L dopamine solution to assemble the polydopamine transition layer for 6h. After taking it out and cleaning it, it was blown dry with nitrogen gas, and the obtained sample was used for future use.

[0057] Weigh 0.37g of ferrous chloride and 1g of ferric chloride and dissolve them in 30mL of deionized water, then add 50mL of ammonia water (concentration is 25%), place in a 100mL three-necked fl...

Embodiment 3

[0069] This embodiment provides a surface construction method for improving the tribological properties of metal materials and metal material friction systems and improving the corrosion resistance of body fluids. The specific steps are basically the same as in Example 1, except that the quality of the ferrous chloride and ferric chloride added in this example is 1g and 3g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com