Reactor for continuous flow photocatalytic degradation of organic micropollutants

A technology for catalytic degradation and pollutants, applied in the direction of water pollutants, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of ineffective degradation of organic micro-pollutants, facilitate subsequent denitrification treatment, and improve sewage treatment Efficiency, the effect of improving degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the cadmium sulfide / molybdenum disulfide nanomaterial photocatalytic film comprises the following steps:

[0051] 1.1) Preparation of rod-shaped cadmium sulfide nanomaterials: hydrated cadmium nitrate and thiourea were added to ethylenediamine solution at a certain molar ratio, stirred evenly, and then transferred to a stainless steel autoclave lined with polytetrafluoroethylene. Keep it under the temperature for a certain period of time, cool to room temperature, wash and dry to obtain rod-shaped cadmium sulfide nanomaterials, and use a quartz mortar to grind into powder;

[0052] 1.2) CdS@MoS with three-dimensional hierarchical structure 2 Preparation of nano-hybrid nanomaterials: add hydrated sodium molybdate and thioacetamide to deionized water at a certain molar ratio, stir evenly, add rod-shaped cadmium sulfide nanomaterials prepared in step 1.1) and stir to form a suspension ; The suspension was transferred to a polytetrafluoroethylene-...

Embodiment 1

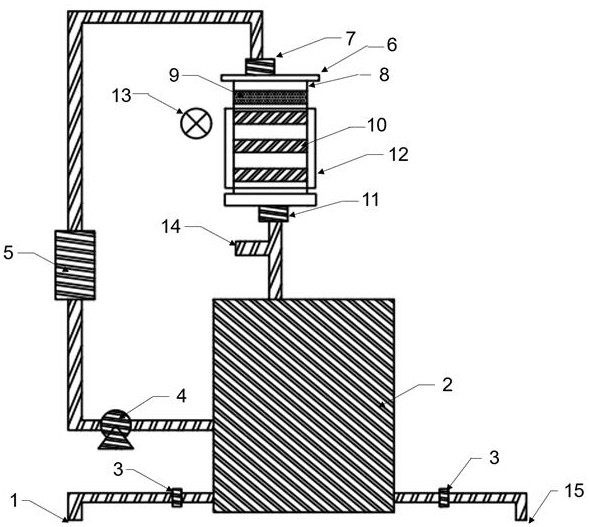

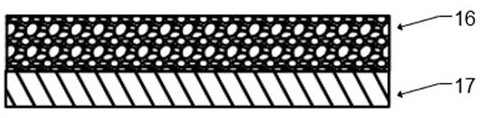

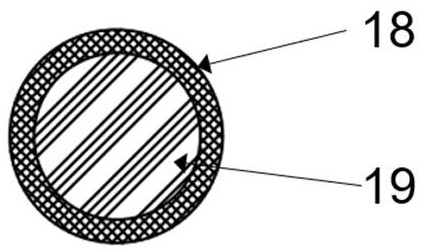

[0062] A reactor for continuous photocatalytic degradation of organic micro-pollutants, its structure includes a stainless steel water tank, a self-priming pump 4, a flow meter 5 and a photocatalytic membrane reactor; the photocatalytic membrane reactor includes a light source assembly and a Reaction container 6; the light source assembly includes an LED light barrel and a fan 13 outside the LED light barrel, and the fan is used for cooling the LED light barrel; the reaction container 6 includes a glass reaction chamber, a feed port 7, and a primary filter layer 9. Photocatalytic film layer 10, discharge port 11, sampling port 14; said photocatalytic film layer 10 contains cadmium sulfide / molybdenum disulfide nanomaterial photocatalytic film; said feed port 7, discharge port 11 respectively Located above and below the glass reaction chamber, the sampling port 14 is located in the middle of the connecting pipe between the discharge port 11 and the water tank 2; the sewage to be tr...

Embodiment 2

[0074] A reactor for continuous photocatalytic degradation of organic micro-pollutants, its structure includes a stainless steel water tank, a self-priming pump 4, a flow meter 5 and a photocatalytic membrane reactor; the photocatalytic membrane reactor includes a light source assembly and a Reaction container 6; the light source assembly includes an LED light barrel and a fan 13 outside the LED light barrel, and the fan is used for cooling the LED light barrel; the reaction container 6 includes a glass reaction chamber, a feed port 7, and a primary filter layer 9. Photocatalytic film layer 10, discharge port 11, sampling port 14; the photocatalytic film layer 10 contains cadmium sulfide / molybdenum sulfide nanomaterials; the feed port 7 and the discharge port 11 are respectively located in the glass reaction chamber Above and below, the sampling port 14 is located in the middle of the connecting pipe between the discharge port 11 and the water tank 2; the sewage to be treated e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com