Steel pipe grabbing and transferring device for steel structure building

A transfer device and technology for construction, applied in metal processing, sorting, etc., can solve the problems of high operating experience requirements for staff, reduced steel pipe production efficiency, slow grasping and transfer process, etc., to improve separation and transfer efficiency, transfer The effect of stable process and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

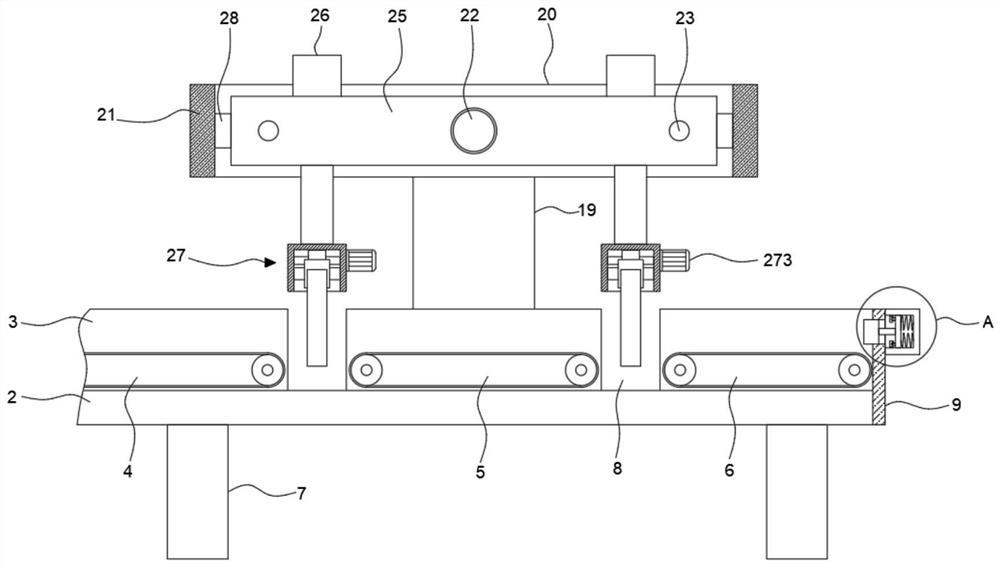

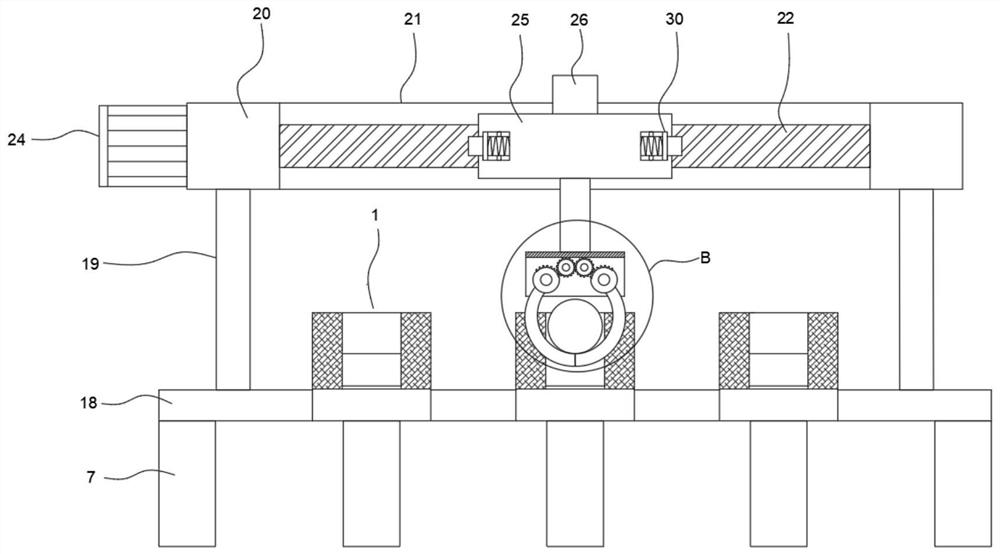

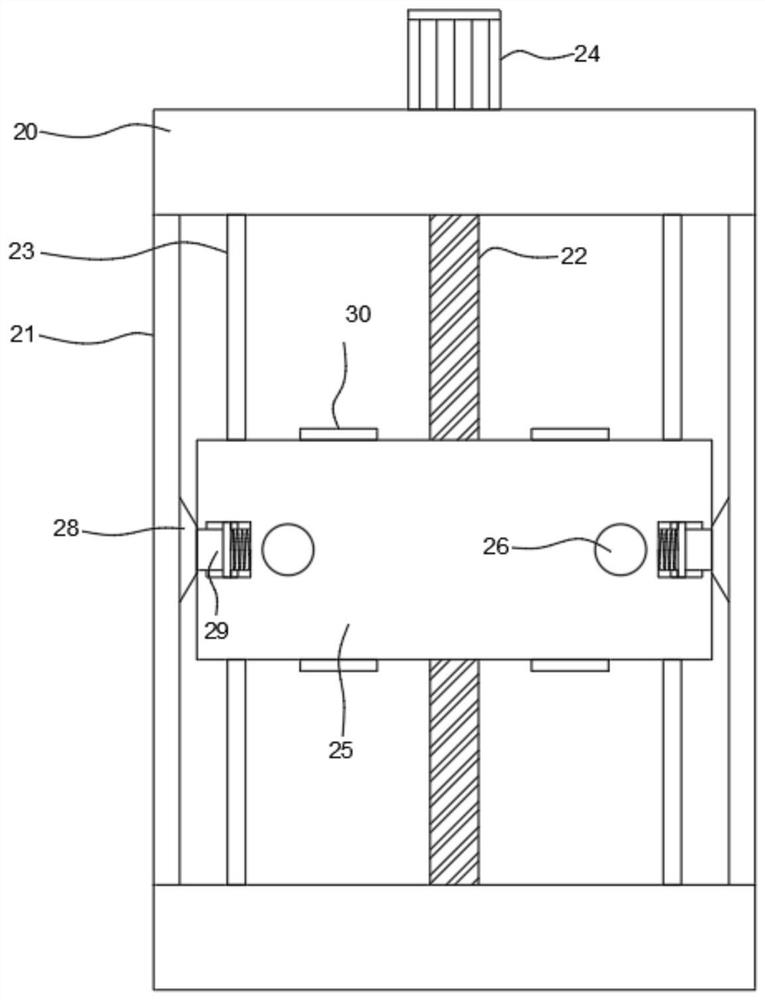

[0025] refer to Figure 1-5 , the grabbing and transferring device for steel pipes used in steel structure buildings, including three conveying devices 1 arranged in parallel, the conveying device 1 in the middle conveys the steel pipes that have detected finished products and defective products, and the conveying devices 1 on both sides carry out the conveying and processing of finished steel pipes For the transportation of defective steel pipes, the conveying device 1 includes a base 2, the upper end of the base 2 is fixedly connected with stoppers 3 on the front and rear sides, and the first conveyor belt 4 and the second conveyor belt 4 are installed between the two stoppers 3 at intervals from left to right. Conveyor belt 5 and the 3rd conveyer belt 6, on the block 3 and between the first conveyer belt 4, the second conveyer belt 5 and the 3rd conveyer belt 6, all have clamping groove 8, so that clamping The device 27 clamps the steel pipe, the base 2 and the right side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com