Composite material and preparation method thereof

A composite material and plate technology, applied in metal rolling and other directions, can solve the problems of low mechanical properties of plates, insufficient surface coloring ability, poor corrosion resistance, etc., and achieve improved mechanical properties, excellent comprehensive mechanical properties, and good deformation consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

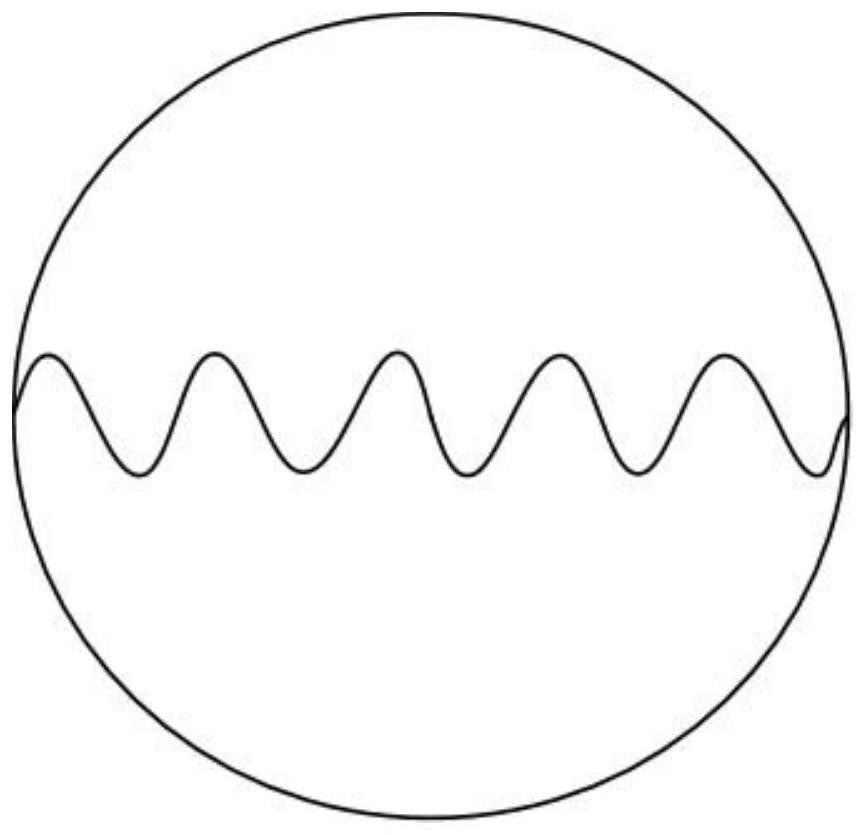

[0055] (1) Material preparation: Prepare two 5052 aluminum alloy and AZ31B magnesium alloy cast rods with a diameter of 300mm and a length of 405mm, and turn them to a diameter of 296mm and a length of 400mm; figure 2 The shown arc-shaped structure that can be concave-convex matched with each other, wherein the vertical distance d between the protrusion and the depression is 130mm;

[0056] (2) Surface polishing: polish the surface of the prepared magnesium alloy and aluminum alloy with sandpaper, remove the surface oxide black skin and wire cutting marks, after all the surface is polished, clean it with tap water, rinse off the surface grinding powder, and then air dry;

[0057] (3) Assembly combination: Combine the cleaned magnesium alloy and aluminum alloy according to the shape of the cylinder to make the two closely fit, and then use a hammer to hit the joint with force, and the joint will be deformed and have a certain binding force. , so that the two are not easy to fa...

Embodiment 2

[0063] (1) Material preparation: Prepare two cast rods of 6061 aluminum alloy and AZ40M magnesium alloy with a diameter of 300mm and a length of 405mm, and turn them to a diameter of 296mm and a length of 400mm; figure 2 The arc-shaped structure shown, wherein the vertical distance d between the protrusion and the depression is 120mm;

[0064] (2) Surface polishing: polish the surface of the prepared magnesium alloy and aluminum alloy with sandpaper, remove the surface oxide black skin and wire cutting marks, after all the surface is polished, clean with alcohol, rinse off the surface grinding powder, and then air dry;

[0065] (3) Assembly combination: Combine the cleaned magnesium alloy and aluminum alloy according to the shape of the cylinder to make the two closely fit, and then use a hammer to hit the joint with force, and the joint will be deformed and have a certain binding force. , so that the two are not easy to fall off;

[0066] (4) Place the assembled composite m...

Embodiment 3

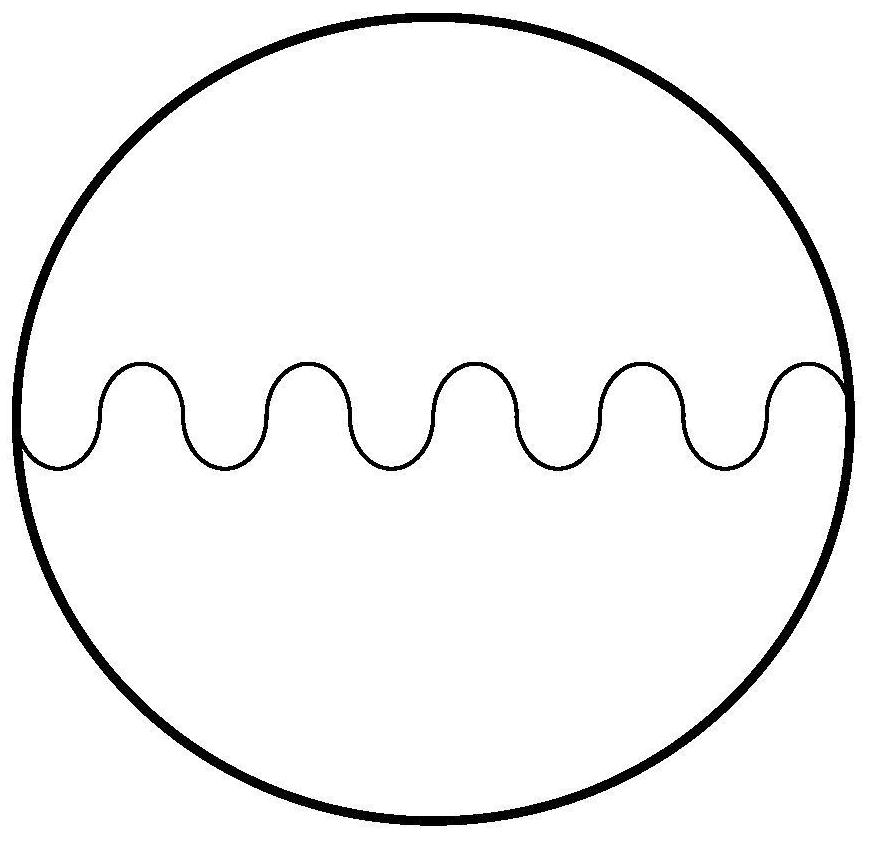

[0071] (1) Material preparation: Prepare two 5052 aluminum alloy and AZ31B magnesium alloy cast rods with a diameter of 300mm and a length of 405mm, and turn them to a diameter of 296mm and a length of 400mm; image 3 The arc-shaped structure shown, wherein the vertical distance d between the protrusion and the depression is 130mm;

[0072] (2) Surface polishing: polish the surface of the prepared magnesium alloy and aluminum alloy with sandpaper, remove the surface oxide black skin and wire cutting marks, after all the surface is polished, clean it with tap water, rinse off the surface grinding powder, and then air dry;

[0073] (3) Assembly combination: Combine the cleaned magnesium alloy and aluminum alloy according to the shape of the cylinder to make the two closely fit, and then pressurize with a hydraulic press, the reduction amount is 1mm, and deformation occurs at the joint. A certain binding force makes the two not easy to fall off;

[0074] (4) Place the assembled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com