A processing technology for improving the utilization rate of expanded cut stem raw materials

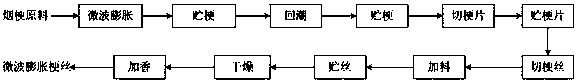

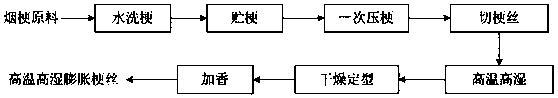

A technology of processing technology and utilization rate, which is applied in the field of processing technology to improve the utilization rate of raw materials of expanded cut stems. It can solve the problems of scorched smell, low moisture content of microwave expanded tobacco stems, and poor expansion uniformity, so as to meet the requirements of reducing size uniformity. , Improve sensory quality, good processing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A processing technology for improving the utilization rate of expanded shredded stem raw materials, comprising the following steps:

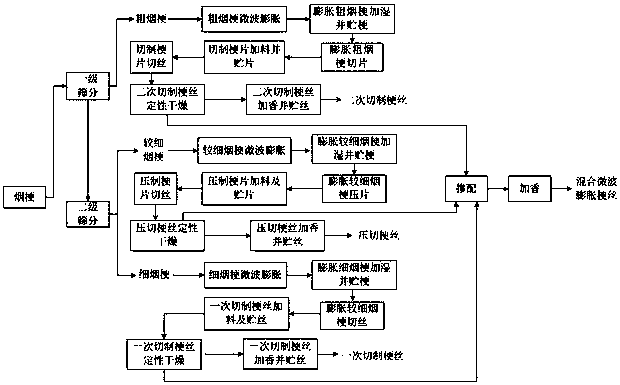

[0054] Step (1), screening of tobacco stems: Put the tobacco stems into the two-stage screening device, the diameter of the screen aperture of the primary screening device × length is 5 mm × 20 mm, and the diameter of the screen aperture of the secondary screening device × length is 3mm×10mm, sieve the tobacco stem raw material into thick tobacco stem, thinner tobacco stem and thin tobacco stem;

[0055] The thick tobacco stem length×diameter≥20mm×5mm, the thin tobacco stem length×diameter≥10mm×3mm and <20mm×5mm, and the thin tobacco stem length×diameter<10mm×3mm;

[0056] Step (2), microwave expansion of tobacco stems: put the thick tobacco stems, thinner tobacco stems, and thin tobacco stems screened out in step (1) into microwave expansion equipment with a frequency of 2450MHz, and control the expanded thick tobacco stems , the thinne...

Embodiment 2

[0074] A processing technology for improving the utilization rate of expanded shredded stem raw materials, comprising the following steps:

[0075] Step (1), screening of tobacco stems: Put the tobacco stems into the two-stage screening device, the diameter of the screen aperture of the primary screening device × length is 5 mm × 20 mm, and the diameter of the screen aperture of the secondary screening device × length is 3mm×10mm, sieve the tobacco stem raw material into thick tobacco stem, thinner tobacco stem and thin tobacco stem;

[0076] The thick tobacco stem length×diameter≥20mm×5mm, the thin tobacco stem length×diameter≥10mm×3mm and <20mm×5mm, and the thin tobacco stem length×diameter<10mm×3mm;

[0077] Step (2), microwave expansion of tobacco stems: put the thick tobacco stems, thinner tobacco stems, and thin tobacco stems screened out in step (1) into microwave expansion equipment with a frequency of 2450MHz, and control the expanded thick tobacco stems , the thinne...

Embodiment 3

[0095] A processing technology for improving the utilization rate of expanded shredded stem raw materials, comprising the following steps:

[0096] Step (1), screening of tobacco stems: Put the tobacco stems into the two-stage screening device, the diameter of the screen aperture of the primary screening device × length is 5 mm × 20 mm, and the diameter of the screen aperture of the secondary screening device × length is 3mm×10mm, sieve the tobacco stem raw material into thick tobacco stem, thinner tobacco stem and thin tobacco stem;

[0097] The thick tobacco stem length×diameter≥20mm×5mm, the thin tobacco stem length×diameter≥10mm×3mm and <20mm×5mm, and the thin tobacco stem length×diameter<10mm×3mm;

[0098] Step (2), microwave expansion of tobacco stems: put the thick tobacco stems, thinner tobacco stems, and thin tobacco stems screened out in step (1) into microwave expansion equipment with a frequency of 2450MHz, and control the expanded thick tobacco stems , The moistu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com