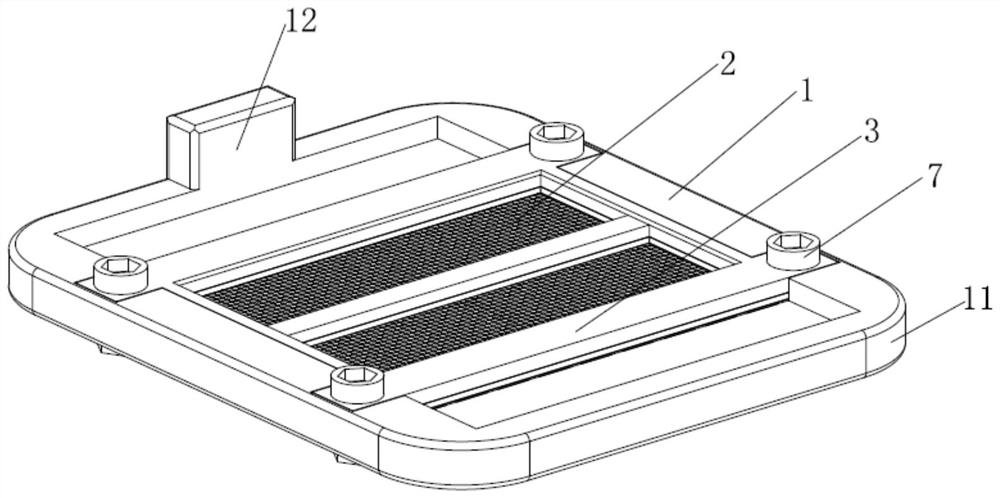

Magnetron sputtering forming device for mechanical performance testing of mesoscale bending specimens

A magnetron sputtering and bending technology, which is used in the application of stable bending force to test the strength of materials, measuring devices, and preparation of samples for testing, which can solve the problem that the magnetron sputtering forming device has not been disclosed, and achieve a clear outline. , good deformation consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]In order to make the technical problems, technical solutions and beneficial effects to be solved by the present application clearer, the present application will be described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present application, but not to limit the present application. The methods used in the present invention are conventional methods unless otherwise specified; the raw materials and devices used are conventional commercial products unless otherwise specified.

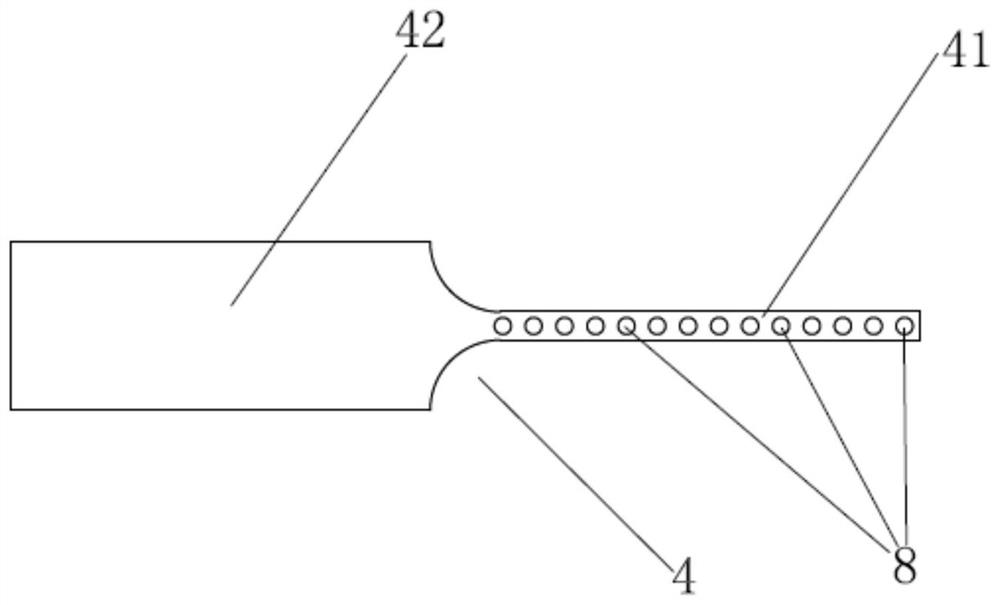

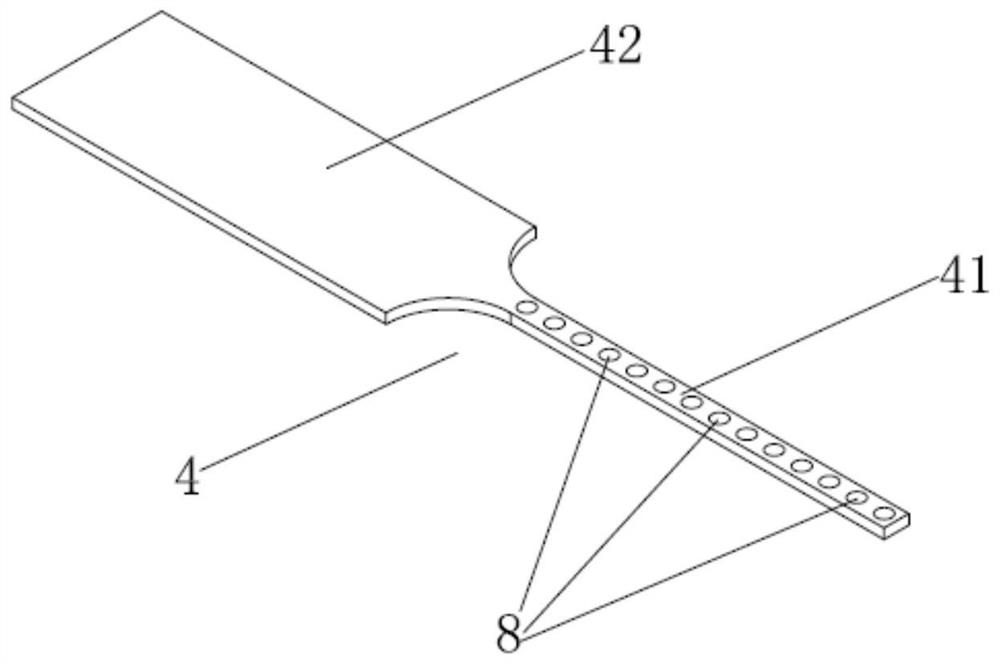

[0032] Depend on figure 2 , image 3 As shown, the mesoscopic scale bending sample 4 has an integrated structure, which is provided with a wide part clamping part 42 and a narrow and long test part 41, and the wide part clamping part 42 is connected to one end of the narrow and long test part 41. The upper and lower surfaces of the long and narrow test portion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com