Mesoscale forming limit bending sample, preparation method and mechanical measurement method

A forming limit and bending technology, applied in the field of strain measurement, can solve the problems of the thickness of the paint on the surface of the sample, the large influence of the bending mechanical properties and resilience performance, and the inability to effectively guide the optimization of the forming process, and achieve the effect of clear outline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

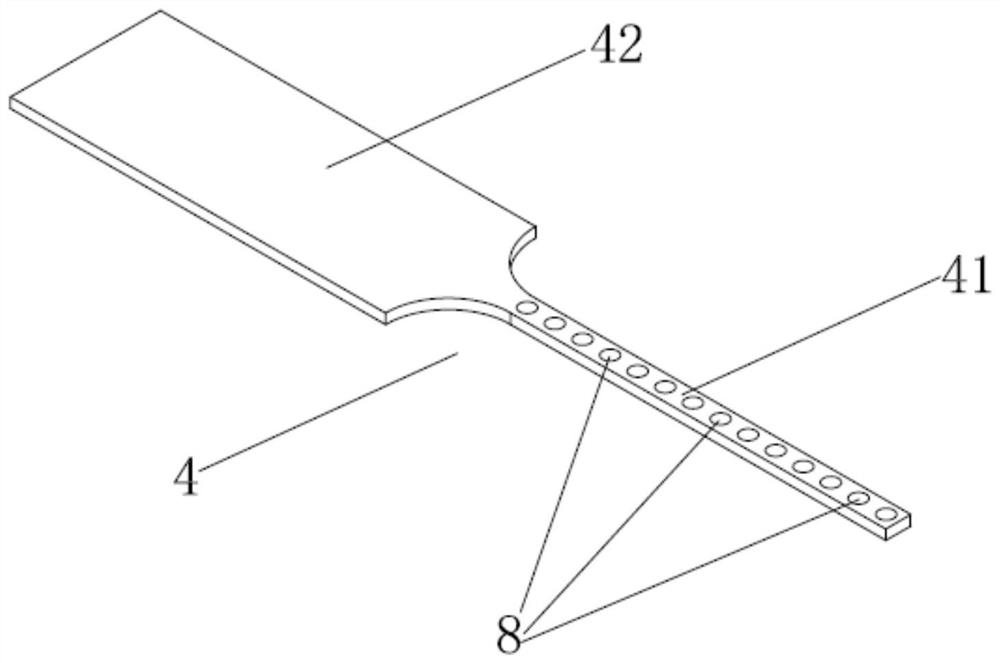

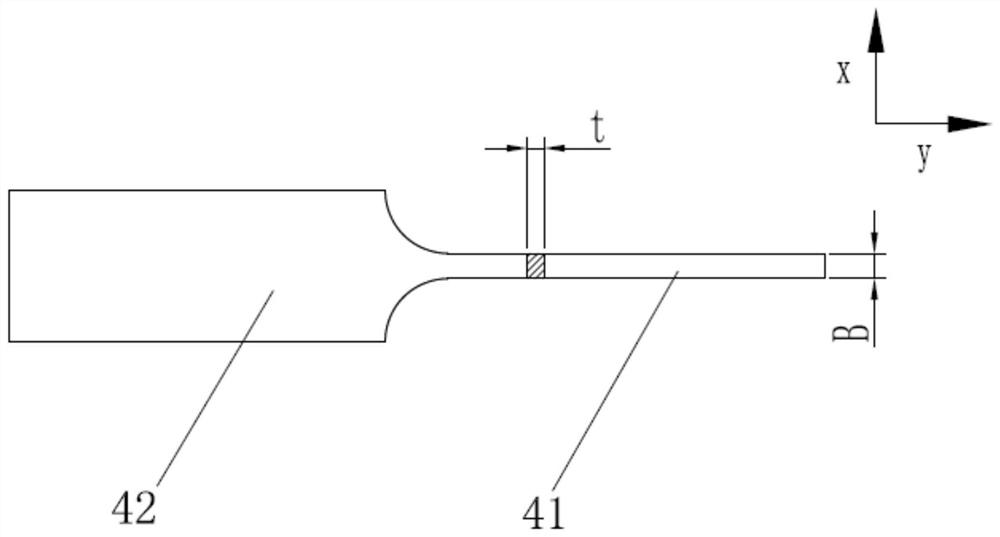

[0057] Depend on figure 1 , figure 2 As shown, the present invention provides a mesoscale forming limit bending specimen, which is provided with a wide clamping part 42 and a narrow and long test part 41, preferably composed of two parts: the wide part clamping part 42 and the narrow and long test part 41 One-piece structure; the clamping part 42 of the wide part is connected to one end of the long and narrow test part 41, and the metal coating 8 is magnetron sputtered on the upper and lower surfaces of the long and narrow test part 41, and the metal coating 8 is used as the mechanical performance test of the bending sample 4 The strain mark; the metal coating 8 is a plurality of tiny circles with mesoscopic dimensions distributed in an array, and the thickness of the metal coating 8 is no more than 200nm.

[0058] The metal coating 8 is preferably distributed in a rectangular array, and the diameter D of the metal coating 8 is 0 It can be 100 μm.

[0059] The size of the ...

Embodiment 2

[0064] The invention provides a method for preparing a mesoscale forming limit bending sample, which comprises the following steps:

[0065] (1) prepare the bending sample 4 described in embodiment 1, the material is pure copper, and the thickness t of the bending sample 4 is no more than 0.2mm;

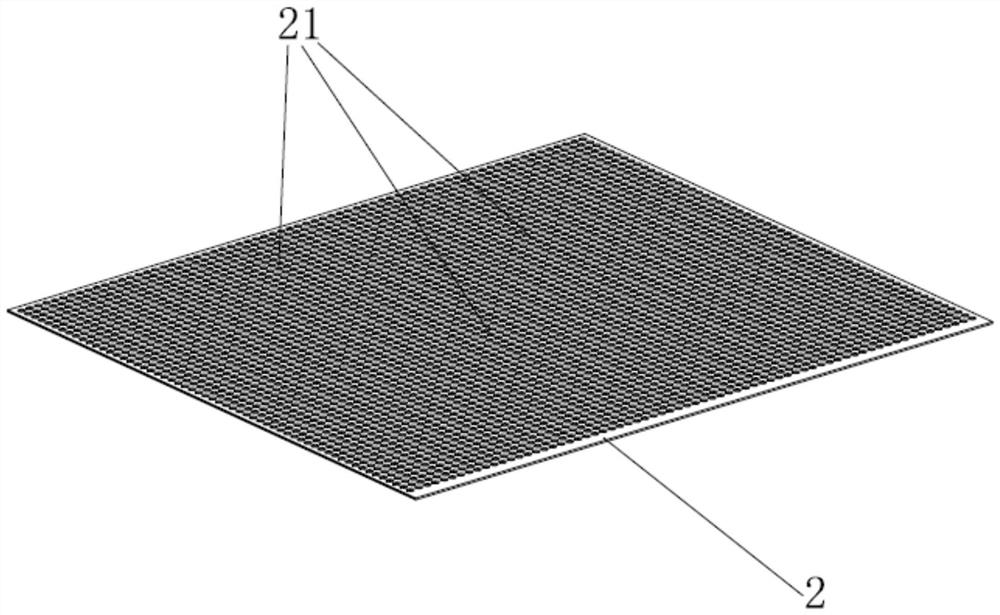

[0066] (2) Prepare a pair such as image 3 The metal-coated forming plate 2 shown is a plate-shaped structure, which is provided with a plurality of first through holes 21 of mesoscopic microscopic geometric figures, and the first through holes 21 are distributed in an array. A through hole 21 is adapted to the size and distribution of the metal coating 8;

[0067](3) A pair of metal-coated forming plates 2 are tightly covered and attached to the upper and lower surfaces of the long and narrow test portion 41 of the bending sample 4; usually the width of the metal-coating forming plate 2 is required to be greater than the width of the long and narrow test portion 41 of the bending s...

Embodiment 3

[0077] In embodiment 2, a pair of metal-coated formed plates 2 are completely tightly covered and attached to the upper and lower surfaces of the elongated test portion 41 of the bending sample 4, and existing technical means such as clamping the two firmly with clips can be used, or The magnetron sputtering forming device of the present invention is adopted.

[0078] Depend on Figure 7-Figure 10 As shown, the magnetron sputtering forming device for the metal coating 8 of the narrow and long test part 41 of the bending sample 4, the magnetron sputtering forming device is provided with a hollow frame 1, a sample positioning frame 5, and a pair of pressing plates 3 , and a pair of metal-coated forming plates 2 described in embodiment 2; by Figure 10 As shown, the sample positioning frame 5 is provided with a placement through hole 51 for placing the bending sample 4, and the placement through hole 51 matches the shape and size of the bending sample 4; the number of placement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com