Mesoscale forming ultimate tensile sample, preparation method and mechanical measurement method

A technology for tensile specimens and forming limits, which is applied in the field of strain measurement, can solve the problems of low strength of specimens, reduced accuracy of forming limit diagrams, inability to effectively guide the optimization of forming processes, etc., to achieve clear outlines and overcome printing grid lines gross effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

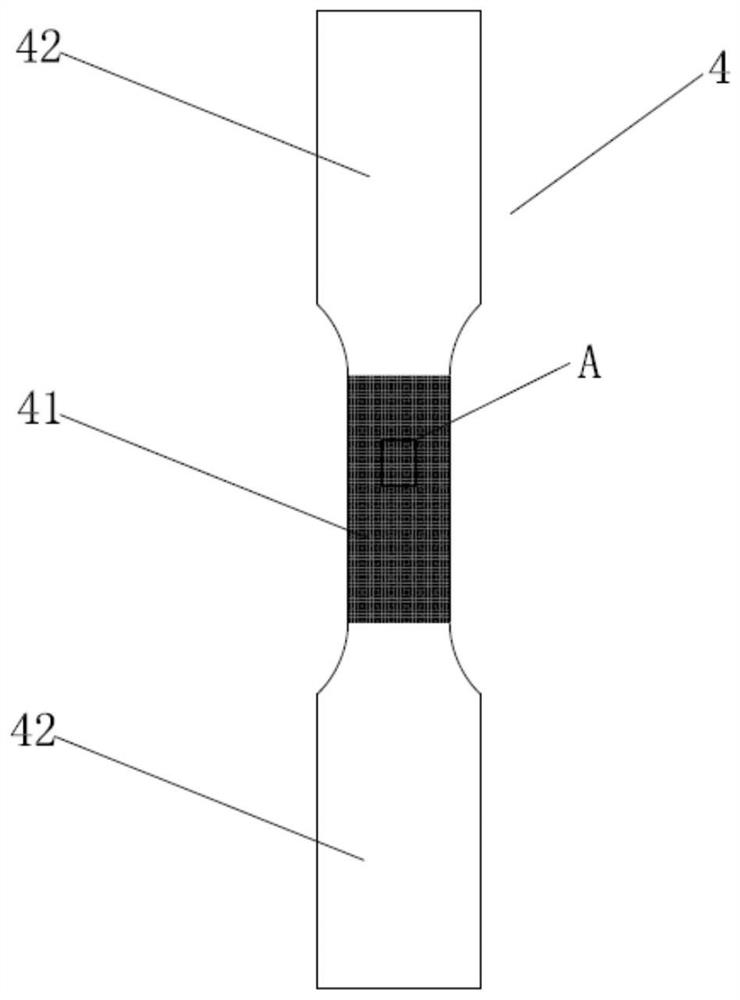

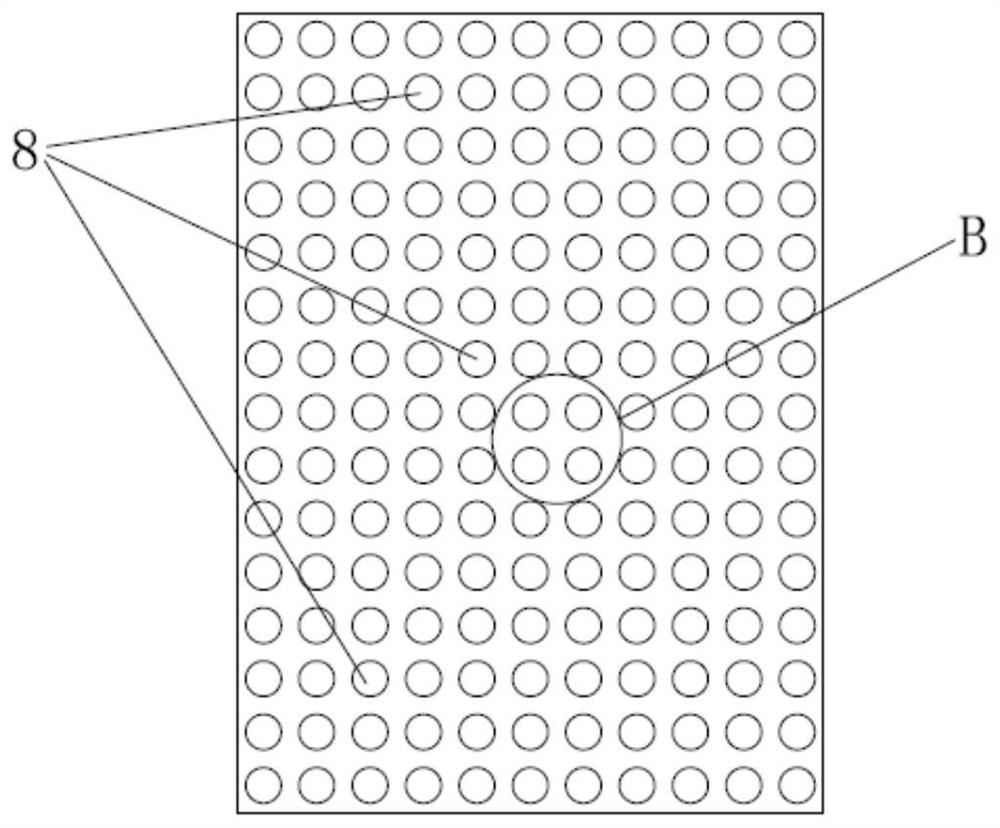

[0056] Depend on figure 1 , image 3 As shown, the present invention provides a mesoscale forming limit tensile sample, the tensile sample 4 is a dumbbell-shaped sample, which is provided with a clamping portion 42 and an intermediate testing portion 41, and on the surface of the intermediate testing portion 41 Magnetron sputtering metal coating 8, metal coating 8 is used as the strain mark of the mechanical performance test of tensile sample 4; The thickness does not exceed 300nm.

[0057] The metal coating 8 can be a plurality of tiny circles with mesoscopic dimensions, preferably distributed in a rectangular array. The thickness of the metal plating film 8 is preferably 100-200 nm.

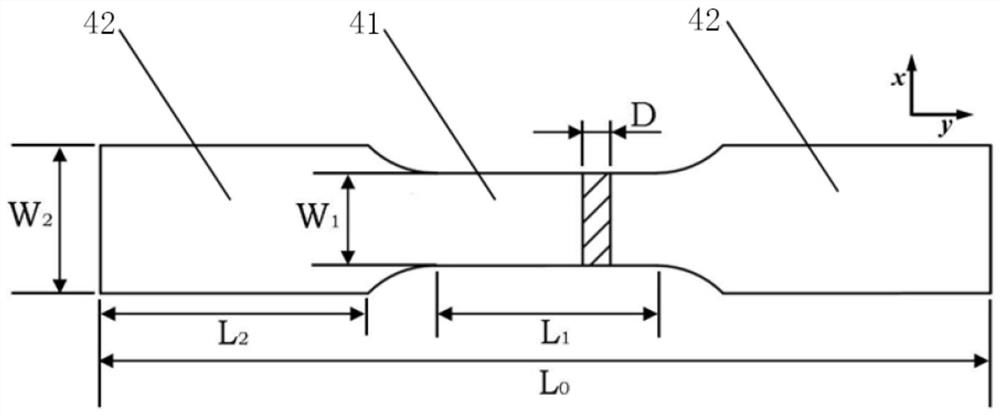

[0058] Tensile sample 4 can be selected according to the actual needs of the mechanical performance test of the material, for example figure 2 As shown, the total length L of tensile specimen 4 0 is 48mm, the thickness D of the tensile sample 4 is 0.2mm; the length L of the middle test pa...

Embodiment 2

[0065] The invention provides a method for preparing a mesoscale forming limit tensile sample, which comprises the following steps:

[0066] (1) prepare the tensile sample 4 described in embodiment 1, this tensile sample 4 is a dumbbell-shaped sample, the material is pure copper, and the thickness D of the tensile sample 4 is no more than 0.5mm;

[0067] (2) Preparation such as Figure 5The metal-coated forming plate 2 shown is a plate-shaped structure, which is provided with a plurality of first through holes 21 of mesoscopic microscopic geometric figures, and the first through holes 21 are distributed in an array. A through hole 21 is adapted to the size and distribution of the metal coating 8;

[0068] (3) The metal-coated formed plate 2 is completely tightly covered and attached to the surface of the middle test portion 41 of the tensile sample 4; usually the width of the metal-coated formed plate 2 is required to be greater than the width of the middle test portion 41 of...

Embodiment 3

[0079] In embodiment 2, the surface of the middle test portion 41 of the tensile sample 4 is fully covered and attached to the metal-coated formed plate 2, and the existing technical means such as clips can be used to clamp the two firmly, and the present invention can also be used. Invented magnetron sputtering forming device.

[0080] The magnetron sputtering forming device of the present invention can carry out appropriate structural design according to the requirements such as the shape and size of the tensile sample 4, so as to be suitable for various metals used for the intermediate test portion 41 of the mesoscale forming limit tensile sample 4 The magnetron sputtering forming of coating film 8, for example by Figure 8 , Figure 9 As shown, the magnetron sputtering forming device is used for the magnetron sputtering forming of the metal coating 8 of the intermediate test portion 41 of the dumbbell-shaped sample. Such as Figure 11 , as shown in FIG. 12, the magnetro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com