Multi-layer composite board and preparation method thereof

A multi-layer composite and plate technology, applied in the field of composite materials, can solve the problems of poor corrosion resistance and low mechanical properties, and achieve the effects of improving comprehensive mechanical properties, reducing surface oxidation, and increasing effective contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

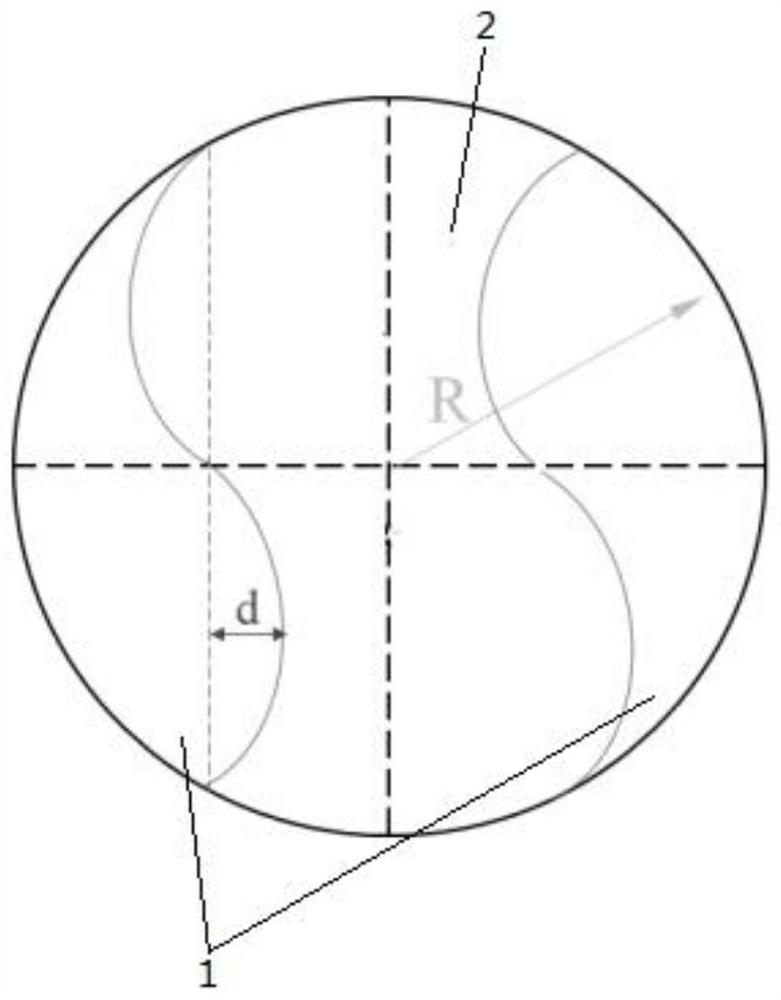

[0031] S1. Material preparation: Prepare two 5052 aluminum alloy and AZ31B magnesium alloy cast rods with a diameter of 300mm and a length of 405mm, and process them to a diameter of 296mm and a length of 400mm; figure 1 For the S-shaped section shown, the distance d between the apex of the convex and concave tangent arcs and the line connecting the two ends is 40mm;

[0032] S2. Surface cleaning: polish the surface of the prepared magnesium alloy and aluminum alloy with sandpaper, remove the surface oxide black skin and wire cutting marks, after all the surface is polished, clean it with tap water, rinse off the surface grinding powder, and then air dry;

[0033] S3. Assembly combination: Combine the cleaned magnesium alloy and aluminum alloy according to the shape of the cylinder to make the layers closely fit, then hit the joint with a hammer to deform the joint and have a certain joint Force, so that the layers are not easy to fall off;

[0034]S4. Place the combined comp...

Embodiment 2

[0037] S1. Material preparation: Prepare two 6061 aluminum alloy and AZ40M magnesium alloy cast rods with a diameter of 300mm and a length of 405mm, and process them to a diameter of 296mm and a length of 400mm; figure 1 For the S-shaped section shown, the distance d between the apex of the convex and concave tangent arcs and the line connecting the two ends is 40mm;

[0038] S2. Surface cleaning: polish the surface of the prepared magnesium alloy and aluminum alloy with sandpaper, remove the surface oxide black skin and wire cutting marks, after all the surface is polished, clean with alcohol, rinse off the surface grinding powder, and then air dry;

[0039] S3. Assembly combination: Combine the cleaned magnesium alloy and aluminum alloy according to the shape of the cylinder to make the layers closely fit, then hit the joint with a hammer to deform the joint and have a certain joint Force, so that the layers are not easy to fall off;

[0040] S4. Place the assembled composi...

Embodiment 3

[0043] S1. Material preparation: Prepare two 5052 aluminum alloy and AZ40M magnesium alloy cast rods with a diameter of 300mm and a length of 405mm, and turn them to a diameter of 296mm and a length of 400mm; figure 1 For the S-shaped section shown, the distance d between the apex of the convex and concave tangent arcs and the line connecting the two ends is 40mm;

[0044] S2, surface cleaning: the aluminum alloy layer is NaHCO with a pH of 10 3 The solution is alkali washed, the magnesium alloy layer is pickled with a phosphoric acid solution with a pH of 6, and then the surface is rinsed with an alcohol solution, and then air-dried;

[0045] S3. Assembly combination: Combine the cleaned magnesium alloy and aluminum alloy according to the shape of the cylinder to make the layers closely fit, and then pressurize with a hydraulic press, with a reduction of 1mm, and deformation occurs at the joint. There is a certain binding force, so that the layers are not easy to fall off; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com