Method for changing Sn-based brazing filler metal welding spot remelting crystal orientation by changing welding parameters

A technology of welding parameters and crystal orientation, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of poor overall performance of solder joints, achieve enhanced anti-electromigration performance, and inhibit electromigration damage behavior , The effect of improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: adopt Ag=3.5wt%, Bi=0.5wt%, In=8.0wt%, Sn=88.0wt% solder paste, take it out from the refrigerator as required, and let it stand in the air for 1 hour ; Grind and polish the surface of the pad and fix the pad spacing to 400 μm; fill the solder between the two pads, and use the brazing process as follows: 5°C / s to 150°C → 1°C / s to 190°C → 12°C / s heating to 245°C → heat preservation → cooling to room temperature in air; heat preservation time is 40s.

Embodiment 2

[0042] Embodiment 2: adopt Ag=3.5wt%, Bi=0.5wt%, In=8.0wt%, Sn=88.0wt% solder paste, take it out from the refrigerator as required, and let it stand in the air for 1 hour ; Grind and polish the surface of the pad and fix the pad spacing to 400 μm; fill the solder between the two pads, and use the brazing process as follows: 5°C / s to 150°C → 1°C / s to 190°C → 12°C / s heating to 280°C → heat preservation → cooling to room temperature in air; heat preservation time is 40s.

Embodiment 3

[0043] Embodiment 3: adopt Ag=3.5wt%, Bi=0.5wt%, In=8.0wt%, Sn=88.0wt% paste solder, take it out from the refrigerator according to requirements, and let it stand in the air for 1 hour ; Grind and polish the surface of the pad and fix the pad spacing to 400 μm; fill the solder between the two pads, and use the brazing process as follows: 5°C / s to 150°C → 1°C / s to 190°C → 12°C / s heating to 310°C → heat preservation → cooling to room temperature in air; heat preservation time is 40s.

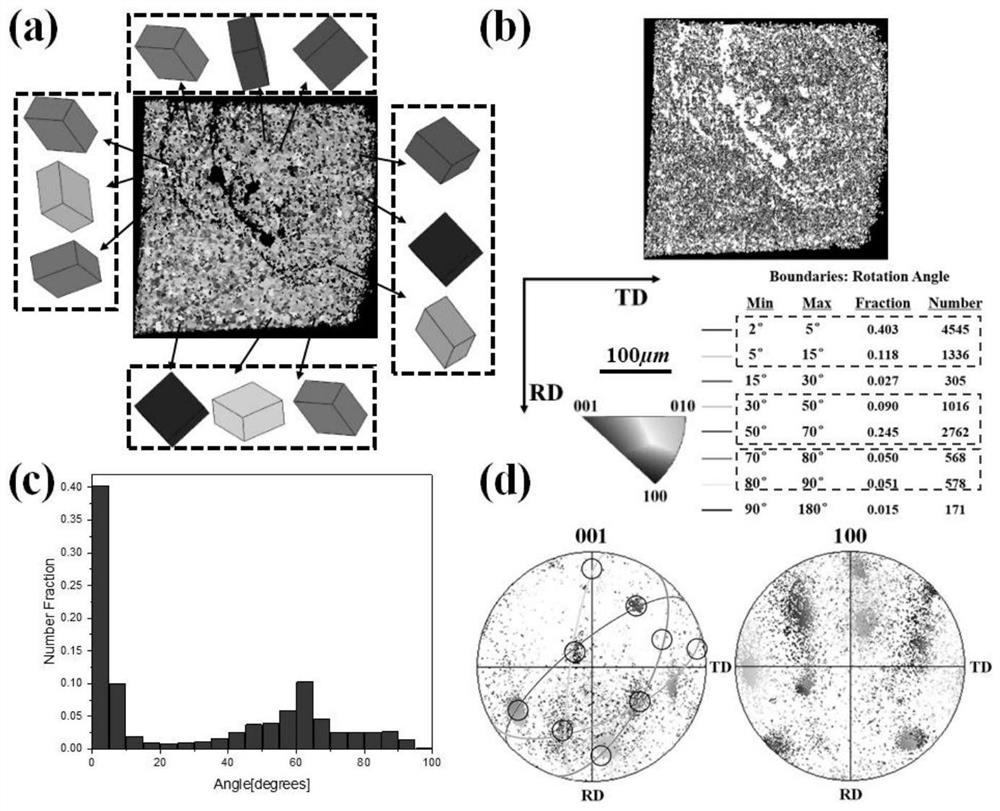

[0044] figure 1 It is the cross-sectional EBSD test diagram of the remelted solder joint in Example 1 at 245°C, wherein (a) grain orientation diagram, (b) grain boundary distribution diagram, (c) misorientation histogram, (d) pole figure, grain The scale bar of the direction diagram and grain boundary distribution diagram is 100 μm. figure 1 It shows that the cross-section of the solder joint is composed of inter-doped and crossed main crystal orientations and fine grain orientations dispersedly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com