Insulating adhesive film with low dielectric loss and preparation method and application thereof

An insulating film and low dielectric technology, applied in the field of resin composite materials, can solve the problems of component heating affecting normal operation, good dielectric loss of insulating film, high dielectric loss and power consumption, etc., to achieve low dielectric loss, The effect of improving signal transmission speed and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

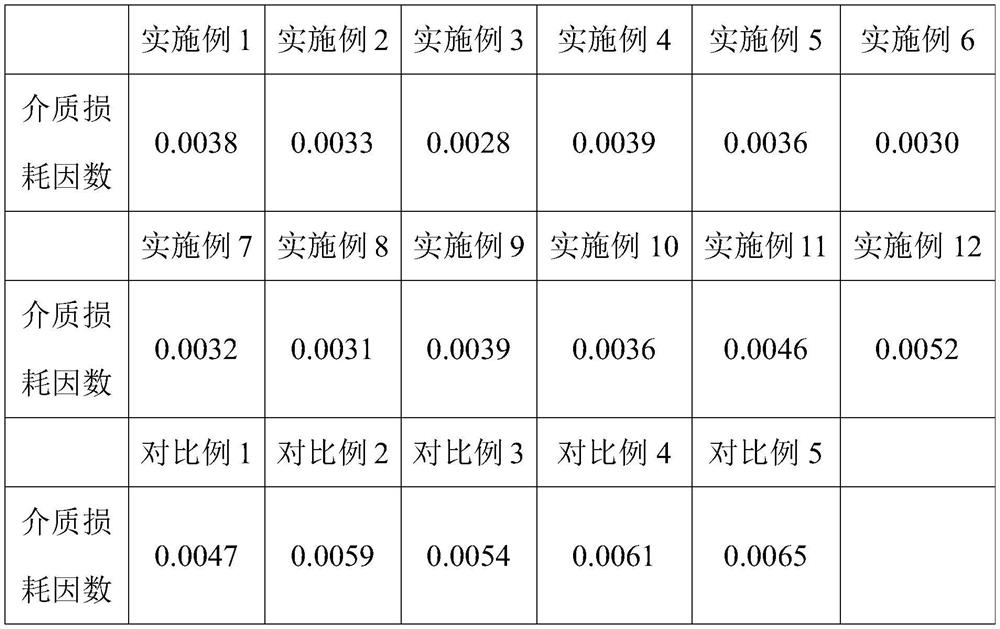

Examples

Embodiment 1

[0089] This embodiment provides an insulating adhesive film with low dielectric loss and a preparation method thereof. The insulating adhesive film with low dielectric loss includes the following components in parts by weight:

[0090] 15 parts of cyanate ester resin, 10 parts of aliphatic bismaleimide resin, 120 parts of silicon dioxide, 25 parts of bisphenol AF type liquid epoxy resin, 1.5 parts of phenoxy resin, diallyl bisphenol A5 parts, 0.5 parts of curing accelerator, 2 parts of flame retardant (HCA-HQ), 3 parts of organic filler and 150 parts of toluene.

[0091] The preparation method of the above-mentioned insulating adhesive film with low dielectric loss is as follows:

[0092] (1) Mix cyanate ester resin, aliphatic bismaleimide resin and toluene evenly, add diallyl bisphenol A and mix, and perform modification treatment at 130°C for 10 minutes, then cool to room temperature, get the mixture;

[0093] (2) After mixing the mixture obtained in step (1) with the rema...

Embodiment 2

[0095] This embodiment provides an insulating adhesive film with low dielectric loss and a preparation method thereof, and the difference from Embodiment 1 is only:

[0096] 5 parts of diallyl bisphenol A are replaced with 2 parts of polyhedral oligomeric silsesquioxane (POSS);

[0097] The preparation method of the above-mentioned insulating adhesive film with low dielectric loss is as follows:

[0098] (1) After mixing cyanate ester resin, aliphatic bismaleimide resin and toluene evenly, add polyhedral oligomeric silsesquioxane (POSS) and mix, and perform modification treatment at 120°C for 15 minutes, Cool to room temperature to obtain the mixture;

[0099] (2) After mixing the mixture obtained in step (1) with the remaining components of the low dielectric loss insulating adhesive film, coat it on the PET release film, dry it at 80°C for 10 minutes, and then remove the PET release film , to obtain a low dielectric loss insulating adhesive film with a thickness of 100 μm....

Embodiment 3

[0101] This embodiment provides an insulating adhesive film with low dielectric loss and a preparation method thereof, and the difference from Embodiment 1 is only:

[0102] Also include 2 parts of polyhedral oligomeric silsesquioxane (POSS) in the insulating adhesive film of described low dielectric loss,

[0103] The preparation method of the above-mentioned insulating adhesive film with low dielectric loss is as follows:

[0104] (1) After mixing cyanate resin, aliphatic bismaleimide resin and toluene evenly, add diallyl bisphenol A and polyhedral oligomeric silsesquioxane (POSS) to mix, and heat After carrying out the modification treatment for 15 minutes at a lower temperature, it was cooled to room temperature to obtain a mixture;

[0105] (2) After mixing the mixture obtained in step (1) with the remaining components of the insulating adhesive film with low dielectric loss, apply it on the PET release film, dry it at 130°C for 3 minutes, and then remove the PET release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com