Ti-A1-V-Y filling layer for titanium alloy welding and welding method of Ti-A1-V-Y filling layer

A ti-a1-v-y, welding method technology, applied in the field of titanium alloy welding, can solve the problems of inability to meet the requirements of the welding process method, narrow welding energy in the welding heat affected zone, and inability to fully meet the use requirements, etc. effect, avoid complicated welding process, improve strength and plastic toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the filling layer is as follows:

[0039] S1. Weigh titanium particles, aluminum particles, vanadium particles and yttrium particles according to the mass percentage content of each metal element in the titanium alloy;

[0040] S2. Put the weighed metal particles into the vacuum induction furnace, turn over and melt repeatedly under the protective gas to obtain the alloy liquid; during the process of repeated turning and melting, the current of the vacuum induction furnace is kept between 200A-250A, and the voltage is kept Between 14V-16V;

[0041] S3. Heat the alloy liquid in a vacuum induction furnace for heat preservation time of 13min-18min, and heat preservation temperature of 1600°C-1800°C;

[0042] S4, casting the alloy liquid after heat preservation to obtain an alloy ingot;

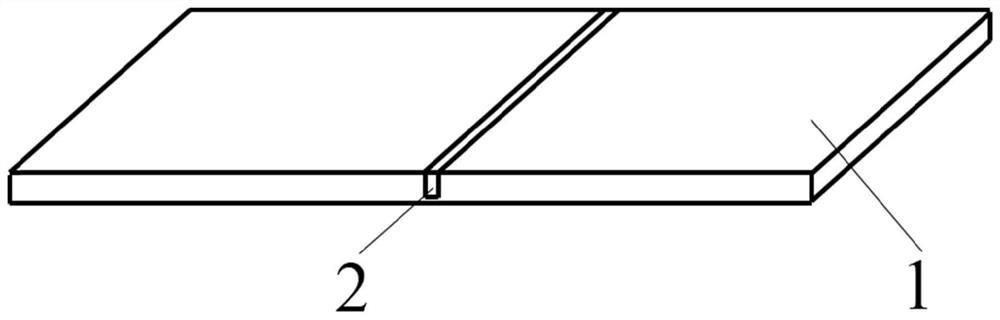

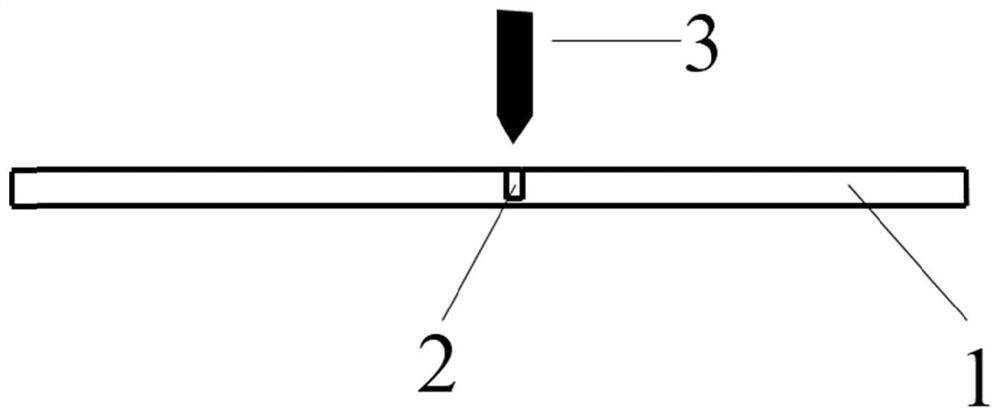

[0043] S5. The alloy ingot is prepared into a filling layer suitable for the U-shaped groove by wire electric discharge cutting.

[0044] Preferably, the mass pe...

Embodiment 1

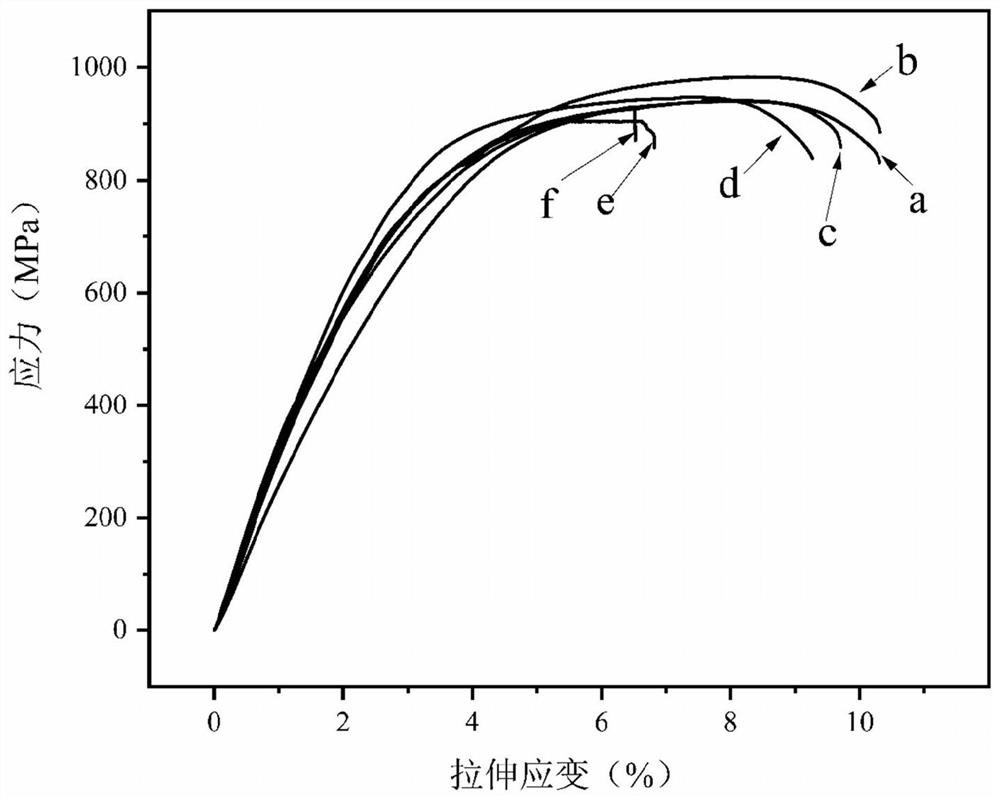

[0057] A Ti-Al-V-Y filling layer for titanium alloy welding and its welding method for titanium alloy welding, the filling layer is composed of metal elements titanium, aluminum, vanadium, yttrium, and the mass percentage of each metal element is aluminum6 %, vanadium 4%, yttrium 0.1%, the balance is titanium;

[0058] The preparation method of the filling layer is as follows:

[0059] S1. Weigh titanium particles, aluminum particles, vanadium particles and yttrium particles according to the mass percentage content of each metal element in the titanium alloy;

[0060] S2. Put the weighed metal particles into the vacuum induction furnace, turn over and melt repeatedly under the protective gas to obtain the alloy liquid; during the process of turning over and melting repeatedly, the current of the vacuum induction furnace is kept at 220A, and the voltage is kept at 15V;

[0061] S3, heat the alloy liquid in a vacuum induction furnace, the heat preservation time is 15min, and th...

Embodiment 2

[0070] The technical features of this embodiment are basically the same as those of Embodiment 1, the only difference being that the mass percentage of yttrium in the filling layer of this embodiment is 0.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com