Polyacrylonitrile/cellulose/hydroxyapatite composite diaphragm as well as preparation method and application thereof

A technology of hydroxyapatite and polyacrylonitrile, which is applied in fiber types, fiber treatment, textiles and papermaking, etc., can solve the problems of poor thermal stability and electrolyte compatibility of polyolefin separators, and achieve excellent thermal stability and porosity Reasonable distribution and the effect of meeting the needs of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

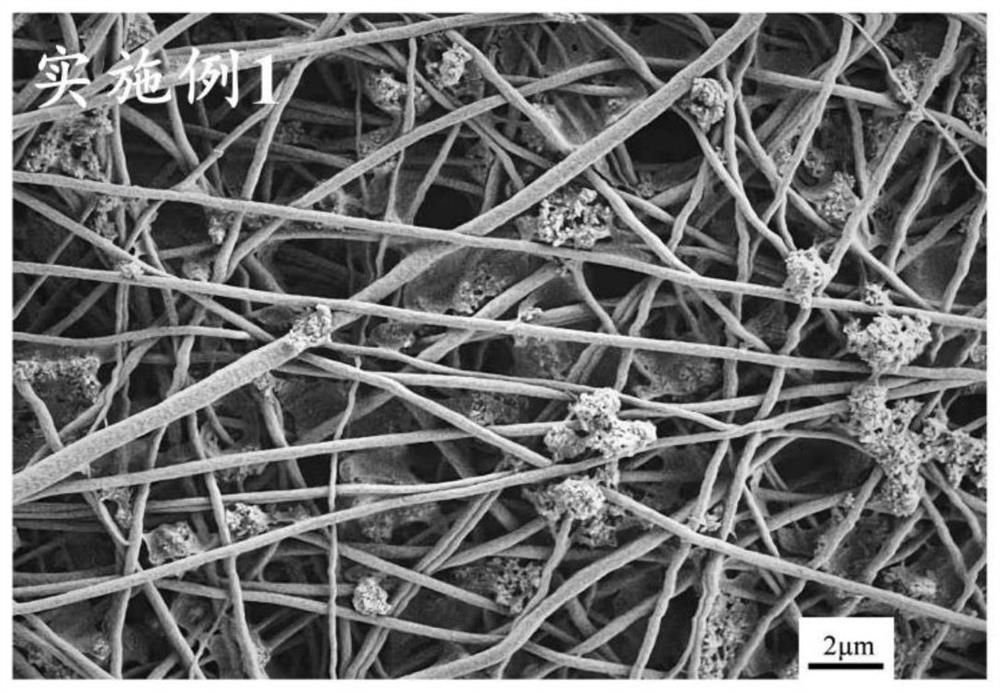

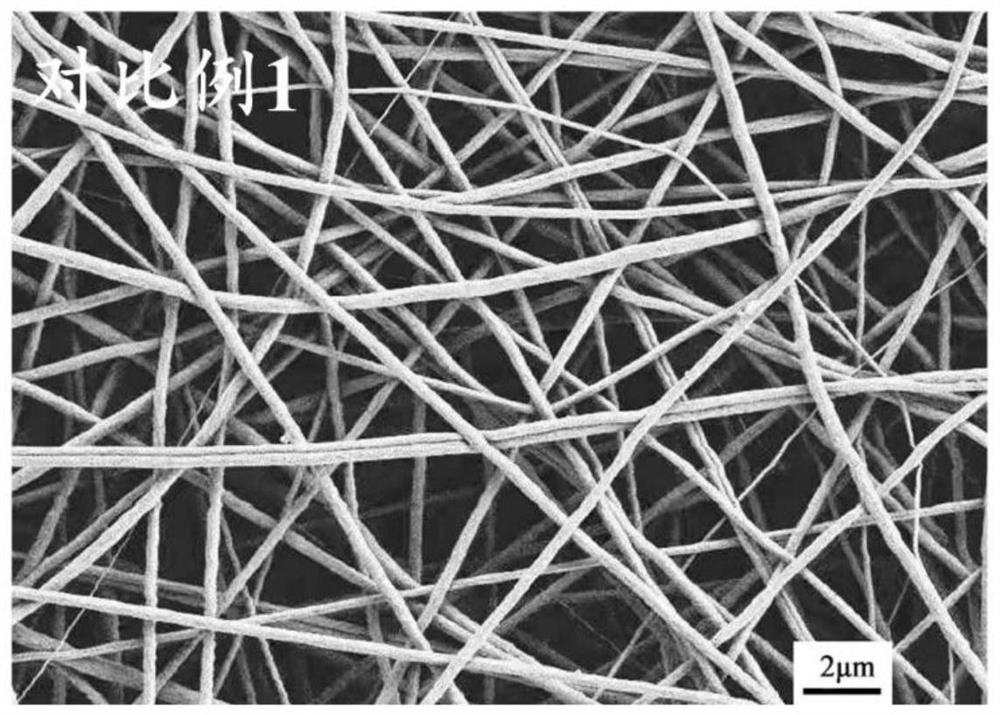

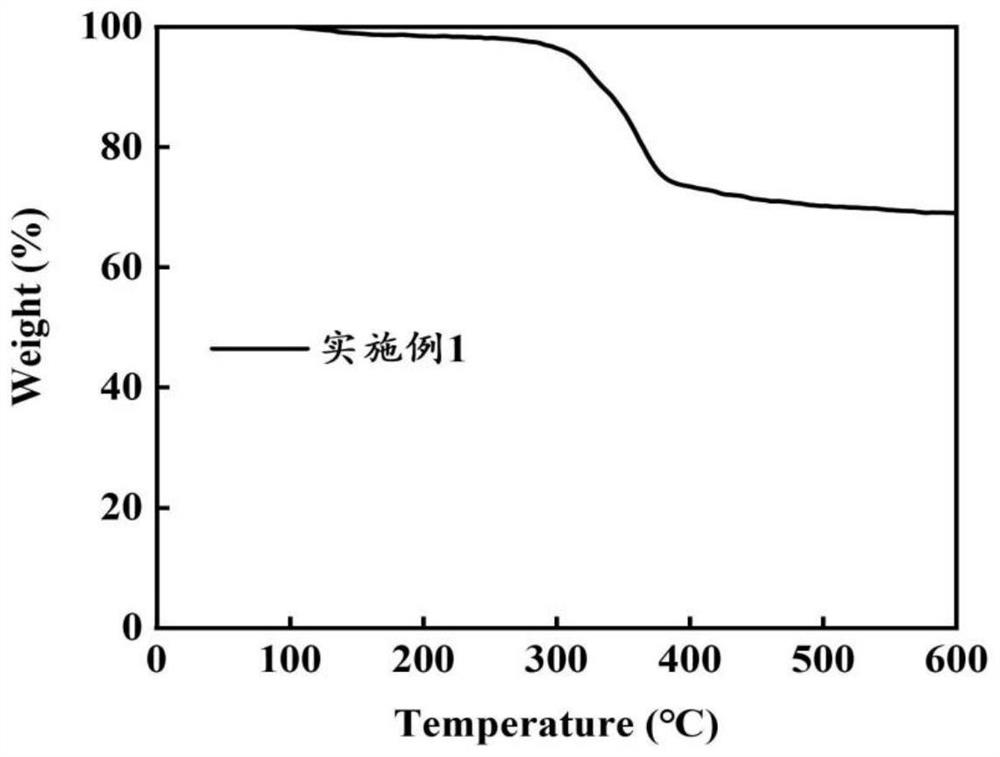

Embodiment 1

[0037] Add 10.49g of vacuum-dried polyacrylonitrile powder into 100.00ml of N,N-dimethylformamide solvent, and magnetically stir at 60°C for 8 hours to obtain polyacrylonitrile spinning solution; use a 10ml disposable medical syringe to extract 5ml of the above-mentioned spinning solution was placed in the injection device of the electrospinning apparatus, and the spinning parameters of positive voltage 16.00KV, negative voltage 2.00KV, receiving distance 15cm, and injection speed 0.09mm / min were adopted. The needle was electrospun for 4 hours to prepare a polyacrylonitrile fiber film with an average diameter of 310 nm. The film was cut into 10cm in length and width, placed between stainless steel plates, clamped with G-shaped clamps, and placed in a blast drying oven at 120°C for 35 minutes to obtain polypropylene with a thickness in the range of 30-55 μm. Nitrile nanofiber membrane.

[0038] 1.50 g of nano-hydroxyapatite and 0.09 g of polyethylene glycol 2000 dispersant wer...

Embodiment 2

[0040] Add 10.49 g of vacuum-dried polyacrylonitrile powder into 100.00 ml of N,N-dimethylformamide solvent, and magnetically stir at 60° C. for 8 hours to prepare a polyacrylonitrile spinning solution. Use a 10ml disposable medical syringe to extract 5ml of the above-mentioned spinning liquid, place it in the injection device of the electrospinning instrument, and take a spinning solution with a positive voltage of 16.00KV, a negative voltage of 2.00KV, a receiving distance of 15cm, and a injection speed of 0.09mm / min. Silk parameters, electrospinning was carried out for 4 hours with a No. 20 spinning needle, and a polyacrylonitrile fiber silk film with an average diameter of 310 nm was prepared. The film was cut into 10cm in length and width, placed between stainless steel plates, clamped with G-shaped clamps, and placed in a blast drying oven at 120°C for 35 minutes to obtain polypropylene with a thickness in the range of 30-55 μm. Nitrile fiber membrane.

[0041] 0.75 g o...

Embodiment 3

[0043] Add 10.49 g of vacuum-dried polyacrylonitrile powder into 100.00 ml of N,N-dimethylformamide solvent, and magnetically stir at 60° C. for 8 hours to prepare a polyacrylonitrile spinning solution. Use a 10ml disposable medical syringe to extract 5ml of the above-mentioned spinning liquid, place it in the injection device of the electrospinning instrument, and take a spinning solution with a positive voltage of 16.00KV, a negative voltage of 2.00KV, a receiving distance of 15cm, and a injection speed of 0.09mm / min. Silk parameters, electrospinning was carried out for 4 hours with a No. 20 spinning needle, and a polyacrylonitrile fiber silk film with an average diameter of 310 nm was prepared. The film was cut into 10cm in length and width, placed between stainless steel plates, clamped with G-shaped clamps, and placed in a blast drying oven at 120°C for 35 minutes to obtain polypropylene with a thickness in the range of 30-55 μm. Nitrile fiber membrane.

[0044] 2.25 g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com