High-strength high-permeability polyethylene sewage treatment membrane and preparation process thereof

A technology of sewage treatment and polyethylene film, which is applied in water/sewage treatment, biological water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of pollution and pollution degradation, and achieve the purpose of inhibiting hole recombination, The effect of improving adsorption and enhancing adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

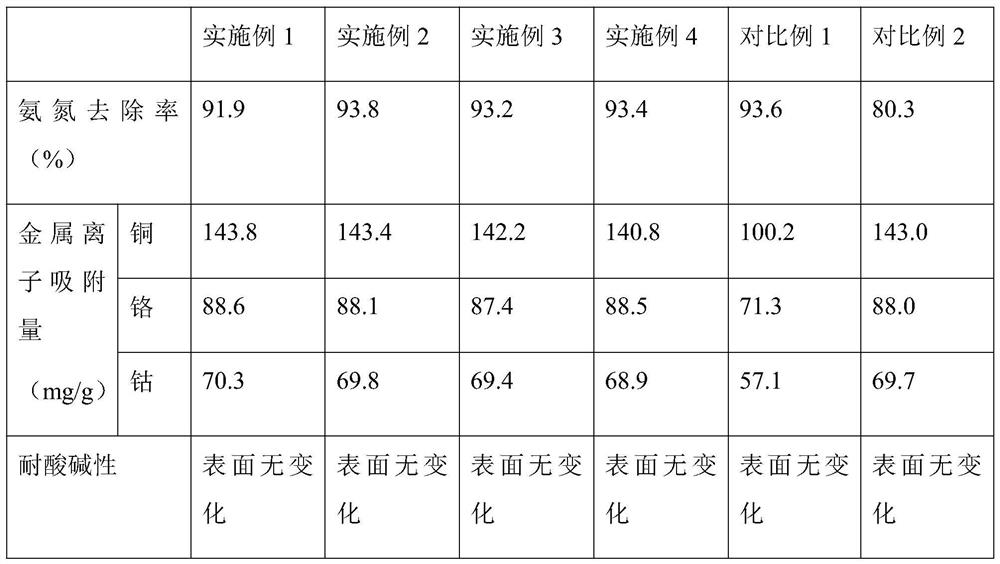

Examples

Embodiment 1

[0036] Embodiment 1: comprise the following steps:

[0037] S1: Mix 10 parts of melamine and 10 parts of dimethyl sulfoxide solution evenly, and react with ultrasound for 10 minutes, which is material A. Mix 10 parts of cyanuric acid and 10 parts of dimethyl sulfoxide solution evenly, and react with ultrasound for 10 minutes, which is Material B, soak 5 parts of hemp stalks in 20 parts of glacial acetic acid, mix well, react for 10 minutes, add 10 parts of dimethyl sulfoxide and 5 parts of N,N,N',N'-tetramethyldiamine, mix After uniformity, slowly add 5 parts of tetrabutyl titanate dropwise, react for 0.5h, heat up to 120°C, react for 10h, filter, wash with ethanol, after drying, mix with material A evenly, ultrasonically react for 10min, add material B, mix Evenly, filter with suction, wash with ethanol, dry, protect with nitrogen, and calcinate at 500°C for 2 hours, which is the biochar-titanium dioxide composite material;

[0038]S2: Add 10 parts of β-cyclodextrin and 15 p...

Embodiment 2

[0043] Embodiment 2: comprise the following steps:

[0044] S1: Mix 12 parts of melamine and 12 parts of dimethyl sulfoxide solution evenly, and react ultrasonically for 12 minutes, which is material A. Mix 12 parts of cyanuric acid and 12 parts of dimethyl sulfoxide solution evenly, and react ultrasonically for 12 minutes, which is Material B, soak 8 parts of hemp stalks in 23 parts of glacial acetic acid, mix well, react for 15 minutes, add 12 parts of dimethyl sulfoxide and 8 parts of N,N,N',N'-tetramethyldiamine, mix After uniformity, slowly add 12 parts of tetrabutyl titanate dropwise, react for 0.6h, heat up to 130°C, react for 12h, filter, wash with ethanol, after drying, mix evenly with material A, ultrasonically react for 11min, add material B, mix Evenly, filter with suction, wash with ethanol, dry, protect with nitrogen, and calcinate at 500°C for 2 hours, that is, biochar-titanium dioxide composite material;

[0045] S2: Add 12 parts of β-cyclodextrin and 20 parts...

Embodiment 3

[0050] Embodiment 3: comprise the following steps:

[0051] S1: Mix 18 parts of melamine and 16 parts of dimethyl sulfoxide solution evenly, and react ultrasonically for 13 minutes, which is material A. Mix 18 parts of cyanuric acid and 16 parts of dimethyl sulfoxide solution evenly, and react ultrasonically for 13 minutes, which is Material B, soak 13 parts of hemp stalks in 28 parts of glacial acetic acid, mix well, react for 18 minutes, add 12 parts of dimethyl sulfoxide and 13 parts of N,N,N',N'-tetramethyldiamine, mix After uniformity, slowly add 18 parts of tetrabutyl titanate dropwise, react for 0.8h, heat up to 140°C, react for 13h, filter, wash with ethanol, after drying, mix evenly with material A, ultrasonically react for 13min, add material B, mix Evenly, filter with suction, wash with ethanol, dry, protect with nitrogen, and calcinate at 500°C for 2 hours, that is, biochar-titanium dioxide composite material;

[0052] S2: Add 18 parts of β-cyclodextrin and 25 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com