PH stabilizer, preparation method thereof, cleaning agent for molybdenum-aluminum-molybdenum coated glass and preparation method of cleaning agent

A technology of coated glass and stabilizer, which is applied in the field of cleaning agents, can solve problems such as aluminum metal being easily corroded, and achieve good synergy, good permeability, and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

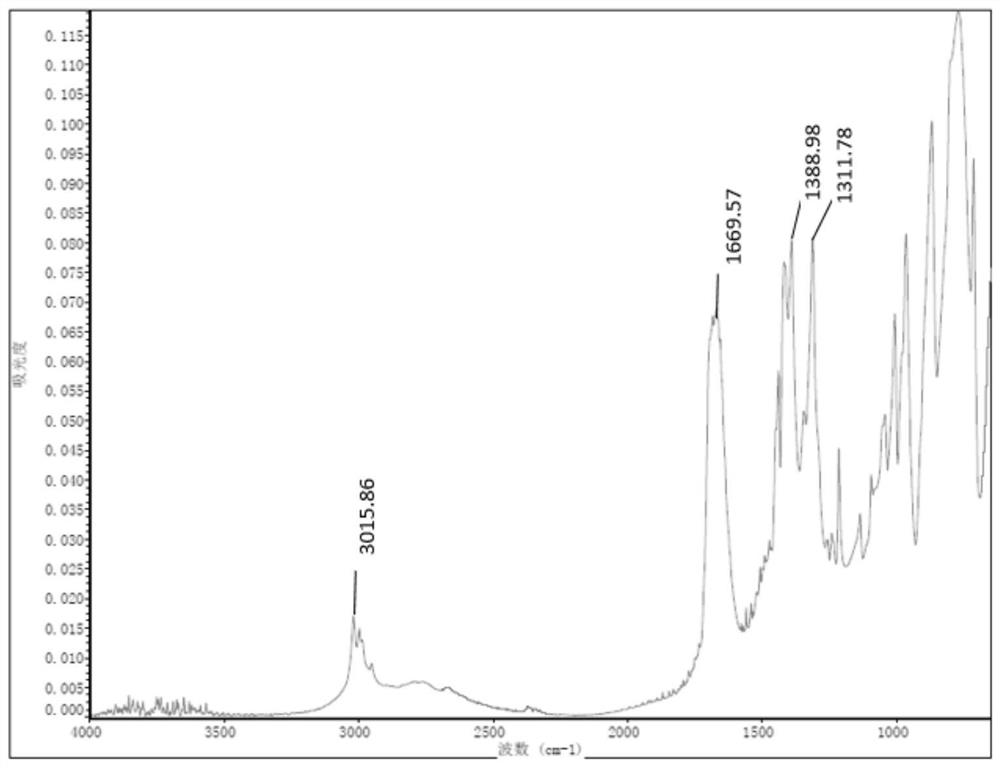

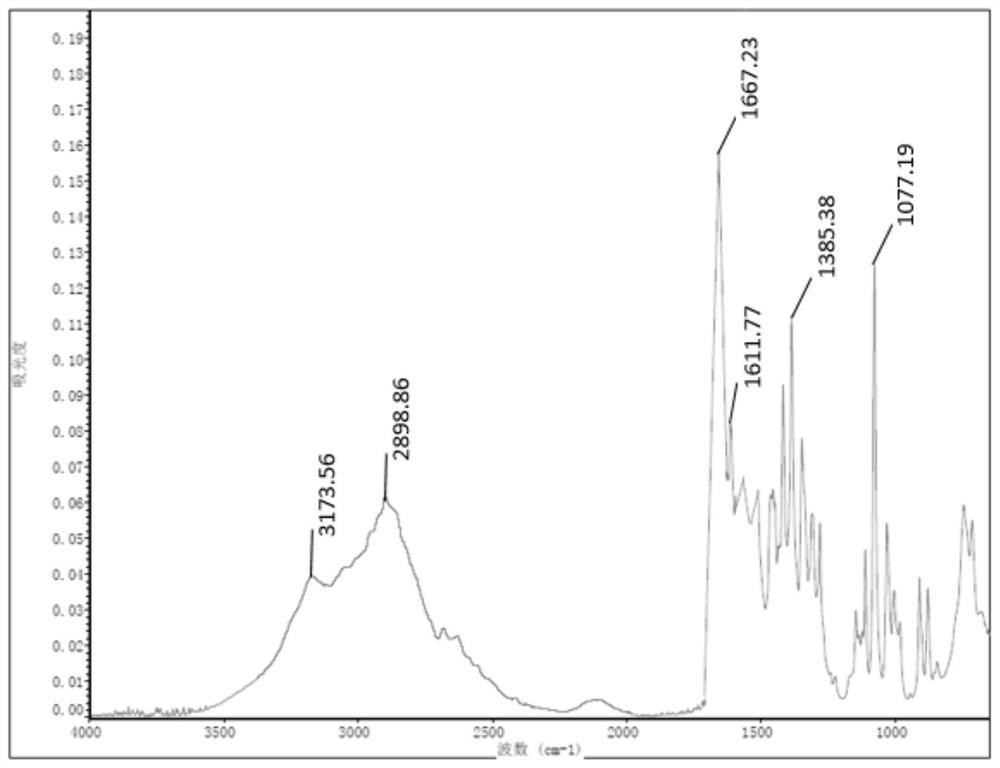

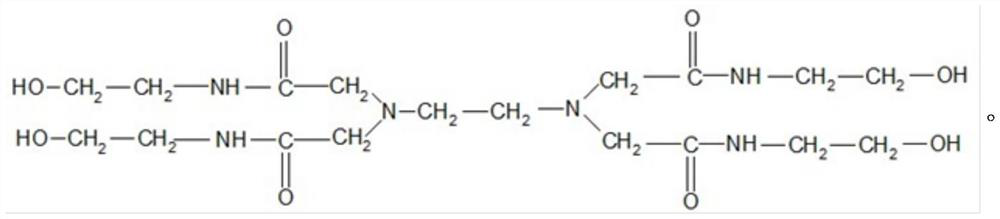

Image

Examples

Embodiment 1

[0047] First take 20g of monoethanolamine and pour it into a round-bottomed flask. After the distillation device is assembled, nitrogen is introduced to protect the monoethanolamine; The molar ratio of monoethanolamine is 1:4. Take 292g of ethylenediaminetetraacetic acid and 232g of monoethanolamine and slowly add them into the round bottom flask containing monoethanolamine for stirring reaction. The stirring speed is controlled at 200r / min, and the stirring time is 2h;

[0048] Turn on the vacuum pump and use the receiving bottle to receive the condensed and recovered water;

[0049]During the reaction period, the acidity of the reaction solution of EDTA and monoethanolamine was detected every 30 minutes: 1 gram of the reaction solution was prepared as a deionized aqueous solution with a mass concentration of 1%, and titrated with 0.1 mol / L standard acid. When the volume of standard acid consumed does not increase (maintains a certain value), it indicates that the acid value ...

Embodiment 2

[0053] The preparation method of this example is exactly the same as that of Example 1, except that the reaction temperature is 110° C. and the stirring time is 3 hours.

Embodiment 3

[0055] The preparation method of Example 3 is exactly the same as that of Preparation Example 1, except that the reaction temperature is 130° C. and the stirring time is 2.5 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com