Chip type aluminum electrolytic capacitor and preparation method thereof

An aluminum electrolytic capacitor and chip technology, which is applied in the field of capacitors, can solve the problems of drying up and failure of electrolyte, thermal expansion of electrolyte, loss of function of capacitor, etc., and achieve the effects of stable physical and chemical properties, reducing heat generation and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

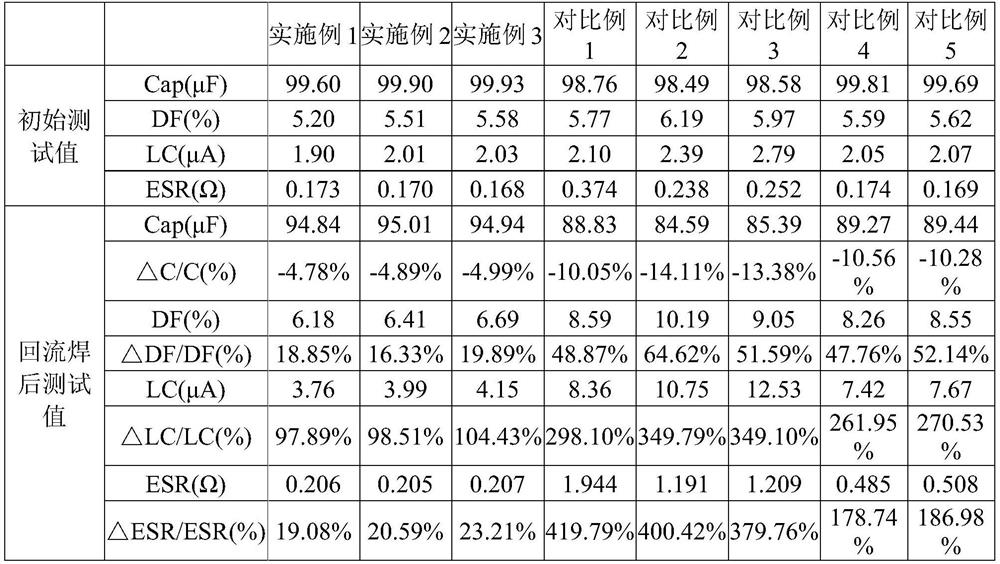

Examples

Embodiment 1

[0037] An electrolyte solution for chip aluminum electrolytic capacitors, which consists of the following components by weight percentage: 58% solvent, 30% solute and 12% additive; wherein,

[0038] The solvent is composed of the following components by weight percentage: 55% ethylene glycol, 25% ethylene glycol monophenyl ether, 12% formamide and 8% gamma-butyrolactone;

[0039] The solute is composed of the following components by weight percentage: ammonium glycolate 60%, ammonium formate 30%, ammonium maleate 8.8%, ammonium dicarboxylate 1.2%;

[0040]The additive is composed of the following components by weight percentage: 45% of carboxylate, 35% of corrosion inhibitor, 15% of ammonium dihydrogen phosphate, 3% of waterproofing agent, 1.2% of ammonium hypophosphite, and 0.8% of succinic anhydride.

[0041] A method for preparing a chip aluminum electrolytic capacitor, comprising the following steps:

[0042] (1) Core package winding: insert electrolytic paper between the...

Embodiment 2

[0048] An electrolyte solution for chip aluminum electrolytic capacitors, which is composed of the following components by weight percentage: 50% solvent, 35% solute and 15% additive; wherein,

[0049] The solvent is composed of the following components by weight percentage: ethylene glycol 60%, ethylene glycol monophenyl ether 20%, formamide 10% and gamma-butyrolactone 10%;

[0050] The solute is composed of the following components by weight percentage: ammonium glycolate 55%, ammonium formate 35%, ammonium maleate 9.2%, ammonium dicarboxylate 0.8%;

[0051] The additive is composed of the following components by weight percentage: 42% of carboxylate, 35% of corrosion inhibitor, 13.9% of ammonium dihydrogen phosphate, 8% of waterproofing agent, 0.6% of ammonium hypophosphite, and 0.5% of succinic anhydride.

[0052] A method for preparing a chip aluminum electrolytic capacitor, comprising the following steps:

[0053] (1) Core package winding: insert electrolytic paper betw...

Embodiment 3

[0059] An electrolyte solution for chip aluminum electrolytic capacitors, which is composed of the following components by weight percentage: 68% of solvent, 24% of solute and 8% of additives; wherein,

[0060] The solvent is composed of the following components by weight percentage: ethylene glycol 45%, ethylene glycol monophenyl ether 30%, formamide 15% and gamma-butyrolactone 10%;

[0061] The solute is composed of the following components by weight percentage: ammonium glycolate 65%, ammonium formate 30%, ammonium maleate 9%, ammonium dicarboxylate 1%;

[0062] The additive is composed of the following components by weight percentage: 50% of carboxylate, 30% of corrosion inhibitor, 11.2% of ammonium dihydrogen phosphate, 8.5% of waterproofing agent, 0.2% of ammonium hypophosphite, and 0.1% of succinic anhydride.

[0063] A method for preparing a chip aluminum electrolytic capacitor, comprising the following steps:

[0064] (1) Core package winding: insert electrolytic pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com