A kind of high temperature resistant polyvinyl chloride/nitrile rubber composite cable material

A technology of composite cable material and polyvinyl chloride, applied in the field of cable material, can solve problems such as poor heat resistance, and achieve the effects of good processability and flow, good discoloration resistance, and improved temperature resistance grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

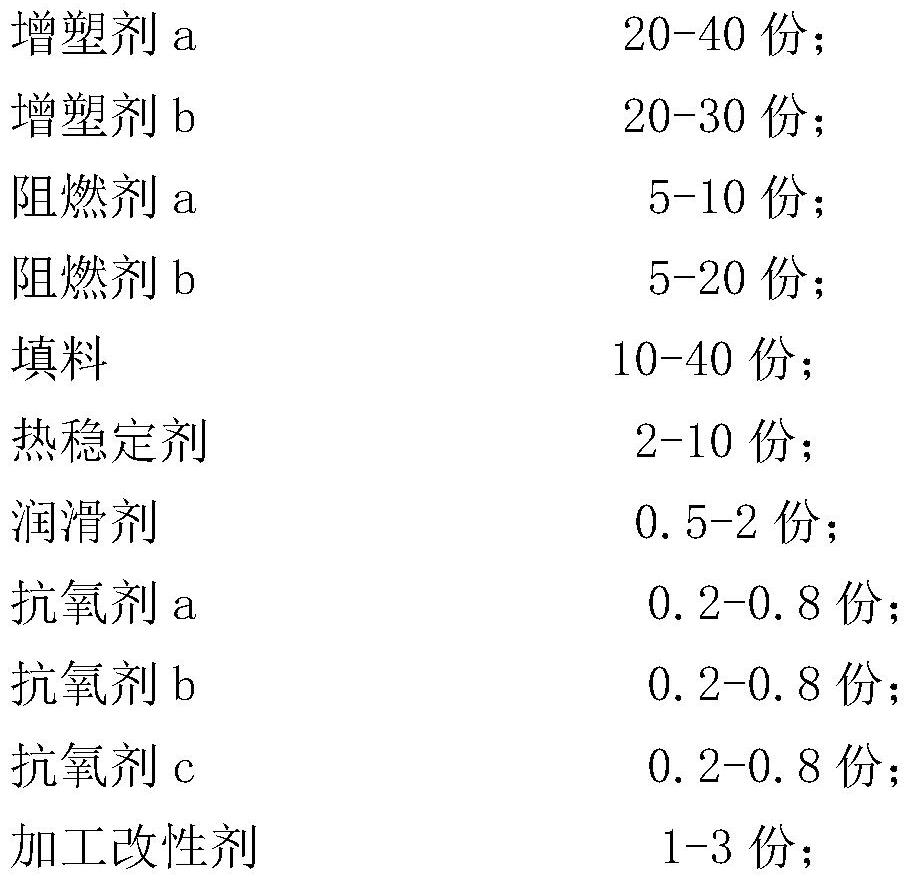

Method used

Image

Examples

Embodiment Construction

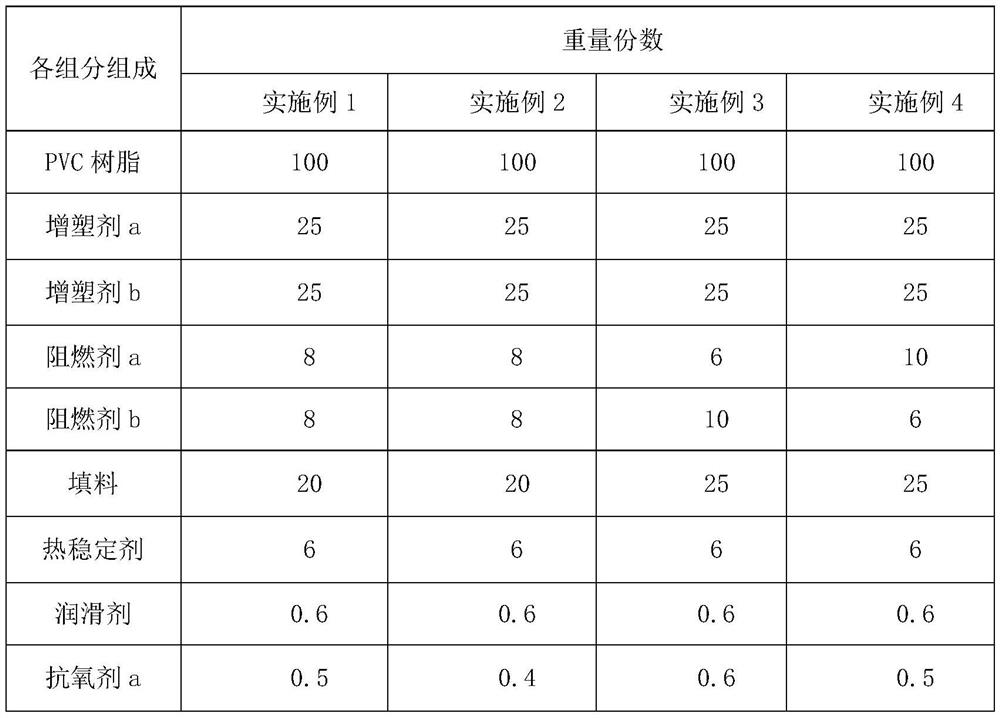

[0039] Below in conjunction with embodiment, the present invention is further described:

[0040] The composition of raw materials in Examples 1-4 is shown in Table 1, and the numerical values of composition of raw materials in Table 1 are all parts by weight.

[0041] The raw material formula of table 1 embodiment 1-4 cable material:

[0042]

[0043]

[0044] Table 2: is the name of each component raw material used in the embodiment:

[0045]

[0046] In Example 1 of the above table, "M" represents 6-(2-benzotriazolyl)-4-tert-pentyl-6'-tert-butyl-4'-methyl-2,2'- Methylene diphenol.

[0047] The production process of Examples 1-4 of the present invention is carried out according to the following steps: the first step, the preparation of raw and auxiliary materials; the second step, the measurement and weighing according to the formula ratio; the third step, the high-speed kneading; the fourth step, the twin-screw extruder unit Carry out extrusion, mixing and pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com