Pole piece and preparation method and application thereof

A pole piece and pole ear technology, applied in the field of pole piece and its preparation, can solve the problems of large internal resistance of the cell, large area, low welding efficiency, etc., and achieve simple production equipment, improved safety performance, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a method of preparing the above-described pole, including the following steps:

[0042] Step 1: Coating the active substance on both sides of the partial region of the composite collector, one or more extreme eating welding positions are determined in the region of the uncoated active material, and the through hole or gap is provided;

[0043] Step 2: Welding the metal sheet to the first metal layer of the composite collector, turning the metal sheet with the first metal layer, and weld the pole welding the second metal of the composite collector. Layers, the poor ear is turned on with the second metal layer;

[0044] Step 3: Welding the metal sheet together with the ear in a through hole or a notch, so that the metal sheet is turned on with the pole to form the pole and the first metal layer and The second metal layer is turned on.

[0045]Further, any step and a plurality of steps can be performed separately or simultaneously.

[0046] ...

Embodiment 1

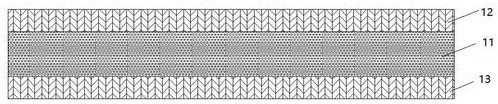

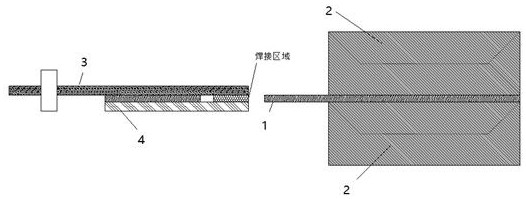

[0050] See figure 1 and figure 2 The preparation steps of the present embodiment are as follows: using aluminum-polyethylene terephthalate-aluminum composite fluid;

[0051] Step 1: Preparation of aluminum metal sheets, a width of 20 mm, length 30 mm, thickness of 0.06 mm;

[0052] Step 2: Lithium cobaltate is applied to the partial region of the aluminum composite collector, selecting a region from 15 mm from the active substance to be uncoated as the extrapolation position;

[0053] Step 3: Use the laser to burn a rectangular through hole in the position of step I, with a width of 6 mm, length 15 mm, to obtain a pole piece with through holes;

[0054] Step 4: Welding aluminum metal sheets on the first aluminum metal layer of the polar composite fluid obtained by the step three, so that the metal sheet is connected to the composite collector first aluminum metal layer;

[0055] Step 5: A aluminum metal layer of a pole composite fluid obtained by having a length of 25 mm is solder...

Embodiment 2

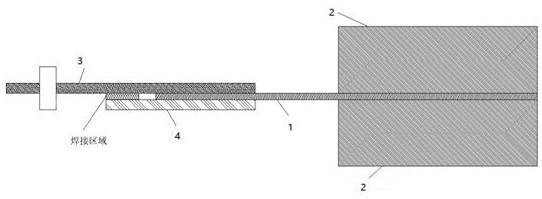

[0059] See image 3 and Figure 4 The preparation steps of the present embodiment are as follows: using copper-polyethylene terephthalate-copper composite fluid;

[0060] Step 1: Preparation of copper metal sheets, its width is 15mm, length 40mm, thickness 0.04 mm;

[0061] Step 2: Apply the human graphite material to the partial area of the current collector, selecting a region where 20 mm from the active substance is not coated as the extract is used as the extrapolate;

[0062] Step 3: A rectangular gap is burned using a laser in step II, which has a width of 8 mm, length 15mm, and obtains a plate with a gap;

[0063] Step 4: The copper metal sheet is easily welded to the first copper metal layer of the polar composite collector of the step three, so that the copper metal sheet is connected to the composite collector first copper metal layer;

[0064] Step 5: Nickel-emitting a nickel-eared, a length of 28 mm, a length of 28 mm, is soldered on the second copper metal layer of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com