Polyurethane as well as preparation method and application thereof

A technology of polyurethane and polymerization reaction, which is applied in the field of medical materials, can solve the problems of affecting the service performance and life of materials in vivo, high requirements for reaction conditions, and high risk of azide groups, etc., and achieves simple methods, simple processing, and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention also provides a kind of preparation method of above-mentioned polyurethane, comprises the following steps:

[0061] Polymerize the chain extender, diisocyanate and polymer diol by one-step method, two-step method or semi-prepolymerization method to obtain polyurethane;

[0062] The polymerization reaction is bulk polymerization or solvent polymerization.

[0063] In the preparation method of polyurethane provided by the present invention, the raw material components and proportions used are the same as above, and will not be repeated here.

[0064] In some embodiments of the present invention, the polymerization reaction may be a one-step solvent polymerization reaction, or a two-step solvent polymerization reaction, or a one-step bulk polymerization reaction.

[0065] In some embodiments of the present invention, the preparation method of the one-step solvent polymerization includes:

[0066] In the mixed solvent, add polymer diol and heat up to...

Embodiment 1

[0096] one-step solvent polymerization

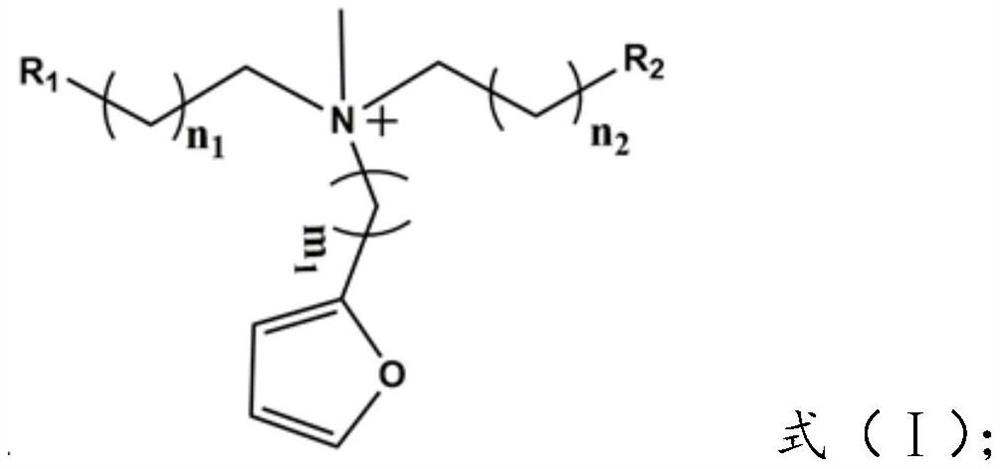

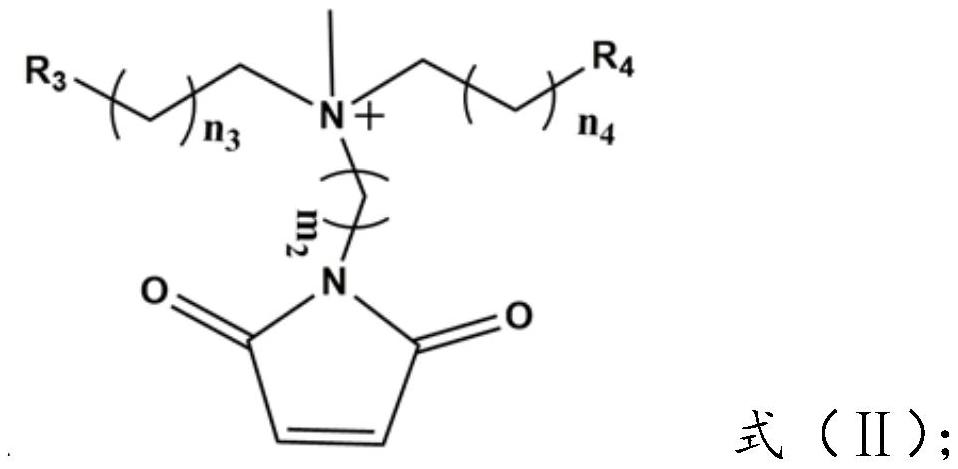

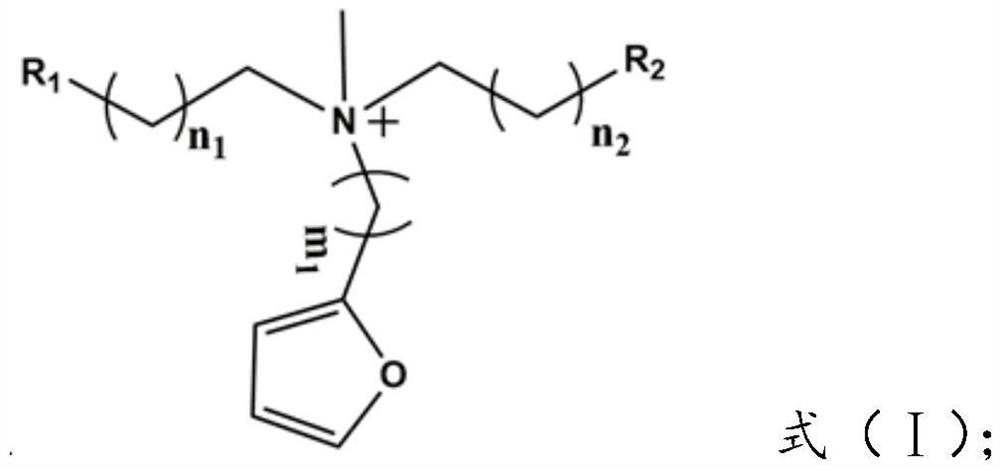

[0097] Add 400mL of a mixed solvent of tetrahydrofuran and N,N-dimethylacetamide (volume ratio 1:4), 50g of polycarbonate diol (polycarbonate containing 1,6-hexanediol) into a four-neck flask (i.e. polycarbonate-1,6-hexanediol), the weight average molecular weight is 1000) after stirring, the temperature is raised to 70°C; add chain extender 10g ethylene glycol, 5g quaternary ammonium-furan diol (with formula The structure shown in (I), m 1 = 2, n 1 = 3, n 2 =3) and 5g quaternary ammonium-maleimide glycol (with structure shown in formula (II), m 2 = 2, n 3 = 3, n 4 =3) Stir fully to dissolve the reactant completely; finally add 20g of 4,4'-diphenylmethane diisocyanate (MDI), raise the temperature to 120°C, and react for 6 hours, then cool down to 70°C to stop stirring and cool to obtain polycarbonate Ester polyurethane solution.

Embodiment 2

[0099] one-step solvent polymerization

[0100] Add 400mL of a mixed solvent of tetrahydrofuran and N,N-dimethylacetamide (volume ratio: 1:4), 50g of polytetramethylene glycol (weight average molecular weight: 1000) into a four-neck flask, stir and heat up to 70°C; add Chain extender 10g ethylene glycol, 5g quaternary ammonium-furan diol (m 1 = 2, n 1 = 3, n 2 =3) and 5g quaternary ammonium-maleimide glycol (m 2 = 2, n 3 = 3, n 4=3) Stir well to dissolve the reactants completely; finally add 20g of 4,4'-diphenylmethane diisocyanate (MDI), raise the temperature to 120°C, stop stirring after 6 hours of reaction and cool down to obtain a polyurethane solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com