Co-doped barium titanate ceramic dielectric material as well as preparation method and application thereof

A technology of ceramic dielectric materials and heterobarium titanate, which is applied in the field of ceramic media, can solve the problems of MLCC reliability reduction, reliability reduction, and grain boundary reduction, so as to improve remanent polarization, improve reliability, and suppress The effect of oxygen vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

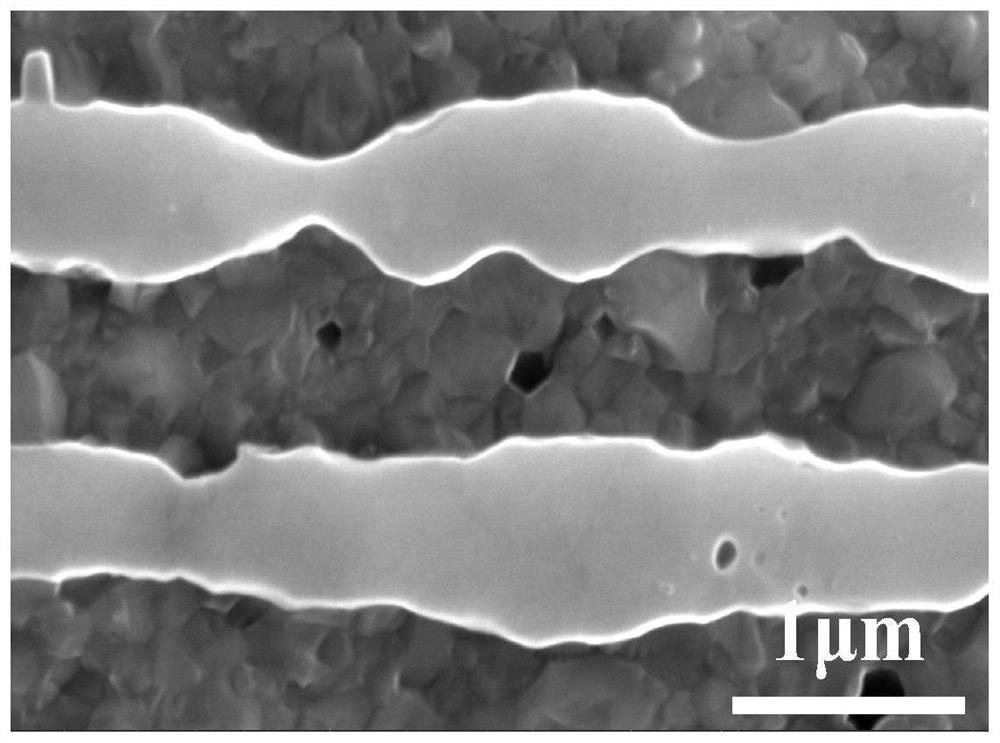

Image

Examples

Embodiment 1

[0080] In this example, the host material BaTiO 3 The particle size of the powder is 200nm (generally there is an error in the size calculated by the electron microscope, that is, 200±10nm is considered normal), the sintering temperature in a reducing atmosphere is 1200°C, the time is 2h, and the temperature is lowered to 950°C for reoxidation After treatment for 2 hours, the composition of the co-doped barium titanate ceramic dielectric material in this example is shown in Table 1, and the performance test of the prepared MLCC sample is shown in Table 2.

[0081] The formula table of table 1 embodiment 1

[0082]

[0083] The performance test result table of table 2 embodiment 1

[0084]

Embodiment 2

[0086] In this example, the host material BaTiO 3 The particle size of the powder is 150nm, the temperature of sintering in a reducing atmosphere is 1300°C, the time is 2h, and the temperature is lowered to 950°C for reoxidation treatment for 2h. The components of the co-doped barium titanate ceramic dielectric material in this example See Table 3, and see Table 4 for the performance tests of the prepared MLCC samples.

[0087] The formula table of table 3 embodiment 2

[0088]

[0089] The performance test result table of table 4 embodiment 2

[0090]

Embodiment 3

[0092] In this example, the host material BaTiO 3 The particle size of the powder is 150nm, the temperature of sintering in a reducing atmosphere is 1280°C, the time is 2h, and the temperature is lowered to 950°C for reoxidation treatment for 2h. The components of the co-doped barium titanate ceramic dielectric material in this example See Table 5, and see Table 6 for the performance tests of the prepared MLCC samples.

[0093] The formula table of table 5 embodiment 3

[0094]

[0095] The performance test result table of table 6 embodiment 3

[0096]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com