Lithium iron phosphate composite material and preparation method and application thereof

A lithium iron phosphate and composite material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problem of low low-temperature conductivity of lithium iron phosphate cathode materials, limiting the electrical properties of lithium iron phosphate cathode materials, and changes in the conductivity of lithium iron phosphate. It can improve the problem of poor low temperature discharge performance, good ionic and electronic conductivity, and improve electronic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

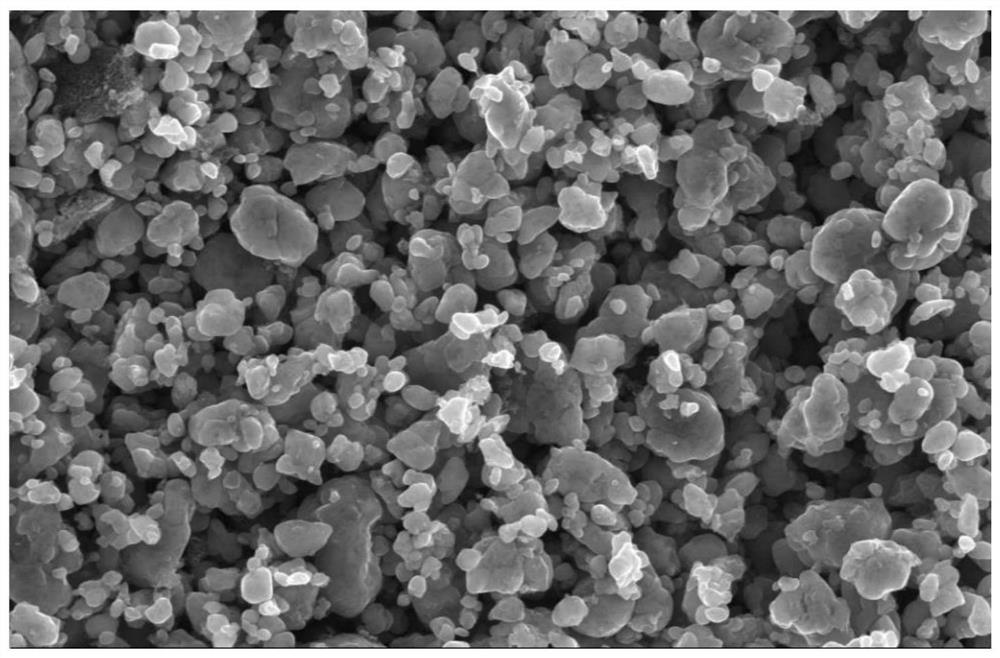

Embodiment 1

[0086] 1. Precursor synthesis stage: carbon-coated LiFePO4 cathode material was prepared by sol-gel method

[0087] According to LiOH, H 3 BO 3 、FePO 4 The molar ratio with citric acid is 0.97:0.03:0.97:3, lithium source, boron source, iron source, phosphorus source are mixed in deionized water (the consumption of deionized water is 3 times of all raw material quality), then add Citric acid and Polyethylene Glycol (Polyethylene Glycol consumption is 1 / 10 of all raw material gross mass) and the glucose of all raw material gross mass 2.0%, form gel in water-bath pot 60 ℃ of stirring 20h, be cooled to room temperature, obtain viscous Thick precursor gel;

[0088] 2. Dry the obtained precursor gel in a vacuum oven at 70°C for 8 hours, then perform ball milling for 2 hours (ball milling frequency 30Hz, ball-to-material ratio 2:1), and finally put the obtained powder in an inert atmosphere protected Sintering in a tube furnace, specifically: pre-sintering at 300°C for 5 hours, t...

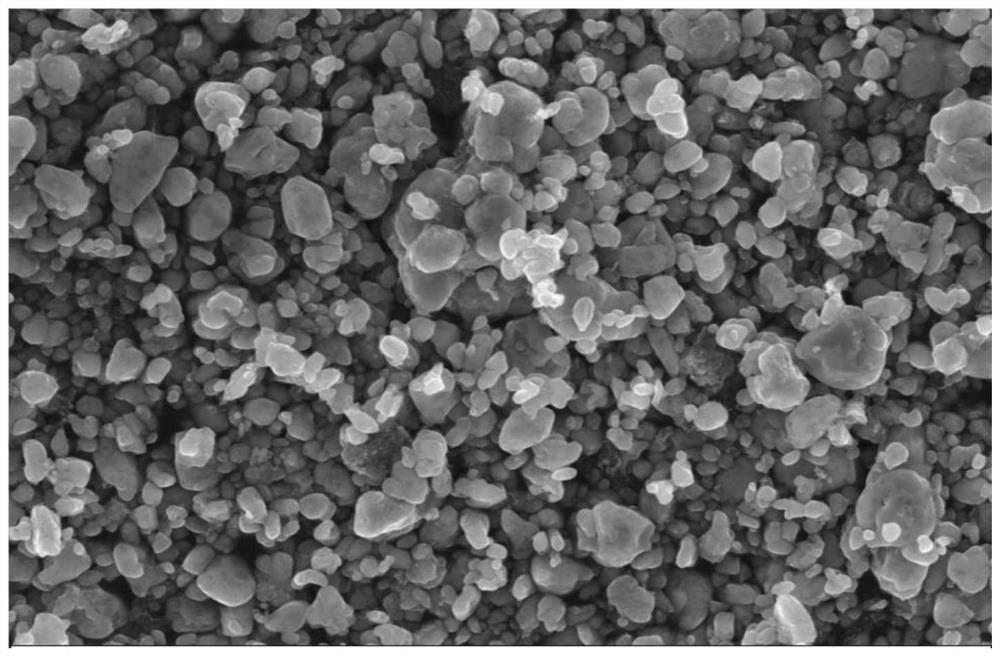

Embodiment 2

[0090] 1. Precursor synthesis stage: Preparation of carbon-coated LiFePO by sol-gel method 4 Cathode material

[0091] According to LiOH, H 3 BO 3 、FePO 4 The molar ratio with citric acid is 0.98:0.05:0.98:3.5, lithium source, boron source, iron source, phosphorus source are mixed in deionized water (the consumption of deionized water is 3 times of all raw material quality), then add Citric acid and polyethylene glycol (the amount of polyethylene glycol is 1 / 10 of the total mass of all raw materials) and 2% glucose of the total mass of all raw materials are stirred in a water bath at 70°C for 15h to form a gel, cooled to room temperature, and viscous Thick precursor gel;

[0092] 2. Dry the obtained precursor gel in a vacuum oven at 75°C for 7 hours, then perform ball milling for 3 hours (ball milling frequency 30Hz, ball-to-material ratio 2:1), and finally put the obtained powder in an inert atmosphere protected Sintering in a tube furnace, specifically: pre-sintering at...

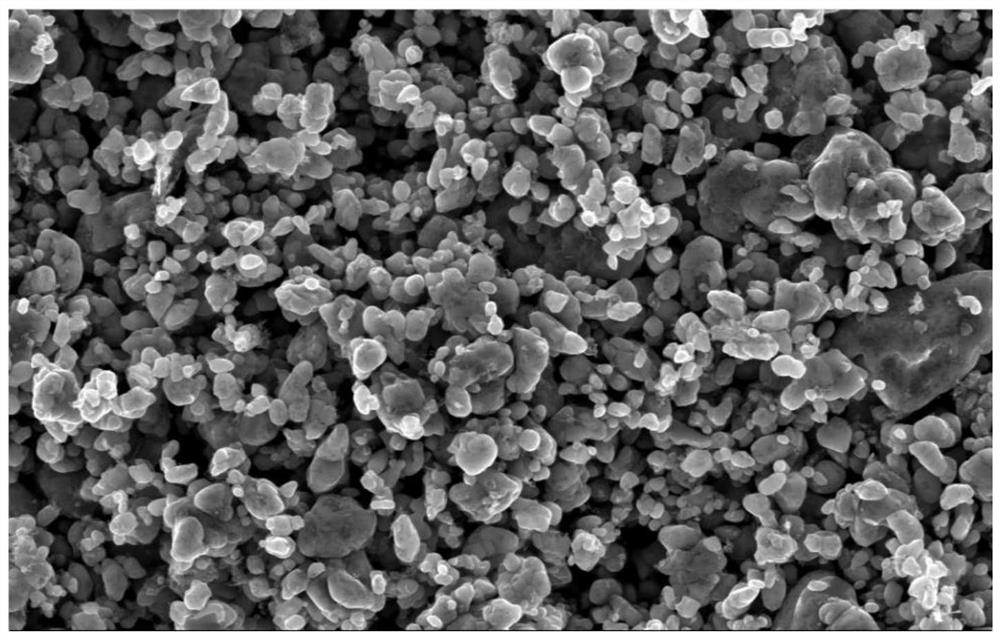

Embodiment 3

[0094] 1. Precursor synthesis stage: Preparation of carbon-coated LiFePO by sol-gel method 4 Cathode material

[0095] According to LiOH, H 3 BO 3 、FePO 4 The molar ratio with citric acid is 1.0:0.05:1.0:4, lithium source, boron source, iron source, phosphorus source are mixed in deionized water (the consumption of deionized water is 3 times of all raw material quality), then add Citric acid and polyethylene glycol (the amount of polyethylene glycol is 1 / 10 of the total mass of all raw materials) and 2% glucose of the total mass of all raw materials are stirred in a water bath at 90 ° C for 10 h to form a gel, cooled to room temperature, and obtained Viscous precursor gel;

[0096] 2. Dry the obtained precursor gel in a vacuum oven at 80°C for 6 hours, then perform ball milling for 4 hours (ball milling frequency 30Hz, ball-to-material ratio 2:1), and finally put the obtained powder in an inert atmosphere protected Sintering in a tube furnace, specifically: pre-sintering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com