Preparation method and application of anti-counterfeit label based on temperature-induced phase change hydrogel

An anti-counterfeiting label and hydrogel technology, applied in the field of anti-counterfeiting label design, can solve the problems of low security of the anti-counterfeiting label, weak pattern coding ability, etc., and achieve high anti-counterfeiting security, simple synthesis method, and obvious change in light transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

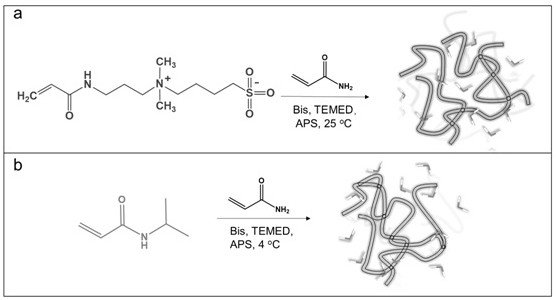

[0031] According to the above ideas, the present invention provides a method for preparing an anti-counterfeiting label based on a thermo-induced phase change hydrogel, such as figure 1 Shown, this preparation method comprises the following steps:

[0032] Step S1, mixing two monomers, N,N-dimethyl(acrylamidopropyl)ammonium butanesulfonate and acrylamide, or isopropylacrylamide and acrylamide to obtain a mixed monomer.

[0033] In the above step S1, N,N-dimethyl(acrylamidopropyl)ammonium butanesulfonate is obtained through the following steps, specifically: 1,4-butane sultone and N-[3-(dimethylamino) Propyl]acrylamide was respectively dissolved in acetonitrile solvent, the two were slowly mixed together, stirred at room temperature 25°C for 1 day, a white precipitate was obtained, and the corresponding product could be obtained after cooling, washing, filtering, and vacuum drying, wherein, 1, The molar ratio of 4-butane sultone and N-[3-(dimethylamino)propyl]acrylamide is 1:1...

Embodiment 1

[0049] The process of preparing an anti-counterfeiting label from a temperature-induced phase change hydrogel based on the highest critical solution temperature is as follows:

[0050] Add 300mg N,N-dimethyl(acrylamidopropyl)ammonium butanesulfonate (NDAABS), 53.07mg acrylamide (AM), 10.36mg N,N'-methylenebisacrylamide (BIS) and 3.83mg persulfuric acid Ammonium (APS) was added to 3.53 mL of water and fully dissolved with magnetic stirring at 25°C;

[0051] Then let it stand at 25°C for more than 30 minutes, then add 2.52uL of N,N,N',N'-tetramethylethylenediamine (TEMED) to the mixture while stirring, and then inject the mixed solution with a syringe Quickly transfer to a transparent acrylic substrate, and stand at 25°C for 12 hours to solidify into a gel. The obtained product can be found in figure 2 As shown in (a), the anti-counterfeiting label is obtained.

Embodiment 2

[0053] refer to figure 2 As shown, the process of preparing an anti-counterfeiting label from a temperature-induced phase change hydrogel based on the lowest critical solution temperature is as follows:

[0054] Add 300 mg of isopropylacrylamide (NIPAAm), 37.69 mg of acrylamide (AM), 4.9 mg of N,N'-methylenebisacrylamide (BIS), and 7.26 mg of ammonium persulfate (APS) into 3.38 mL of water for 25 Magnetic stirring at ℃ to fully dissolve;

[0055] Then freeze and stand at 4°C for more than 30 minutes, then add 3.98uL of N,N,N',N'-tetramethylethylenediamine (TEMED) to the mixture while stirring, and then inject the mixed solution with a syringe Quickly transfer to a transparent substrate made of transparent acrylic, and stand at 4°C for 12 hours to solidify into a gel. The obtained product can be found in figure 2 As shown in (b), the anti-counterfeiting label is obtained.

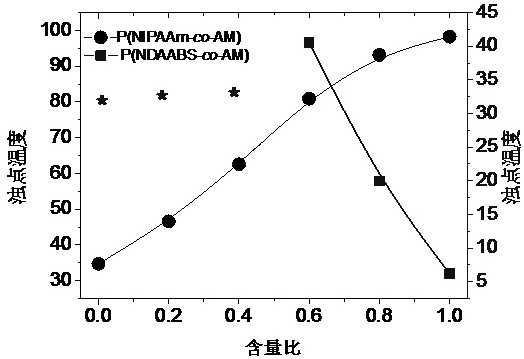

[0056] The method of this example 1 and 2 is changed by changing the acrylamide (AM) and isopropylac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com