High-toughness liquid molding resin based on phase state control technology, composite material and preparation method thereof

A liquid molding and composite material technology, applied in the field of composite materials, can solve the problems of short storage period, increased viscosity of resin system, affecting production and application, etc., to achieve the effect of improving toughness and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] According to a third aspect of the present invention, a method for preparing a high-toughness composite material based on phase control technology is provided, comprising the following steps:

[0032] Step (1), weigh the components of the following mass percentages:

[0033] The liquid thermosetting resin is 60-75%, the curing agent is 20-30%, and the toughening agent is the balance, preferably 2-6%.

[0034]Step (2), mixing the weighed liquid thermosetting resin with the toughening agent, heating and dissolving at 100-140° C. to obtain a transparent liquid resin mixture;

[0035] Step (3), adding a weighed curing agent into the transparent liquid resin mixture, heating and dissolving at 120-150°C to obtain a transparent or translucent liquid molding resin;

[0036] Step (4), heating the liquid molding resin obtained in step (3) to the minimum viscosity temperature of the resin between 100-160°C, when the viscosity reaches the lowest value ≤ 500cP, vacuumize to elimina...

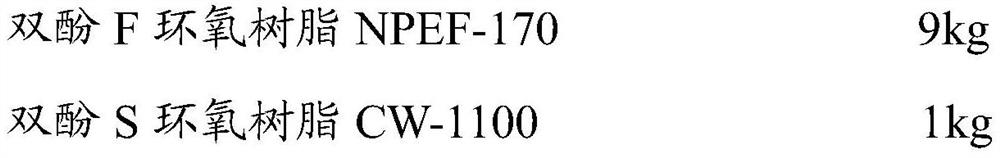

Embodiment 1

[0043] Step (1), weigh each component as required;

[0044]

[0045]

[0046] Among them, the solid toughening agent E21 belongs to the triblock copolymer of styrene-butadiene-methyl methacrylate.

[0047] Step (2), mix the liquid thermosetting resin and the solid toughening agent E21 at room temperature, heat up while stirring, and dissolve at 130±5°C, stir for 120 minutes until the solid toughening agent E21 is completely dissolved, and obtain Liquid resin transparent mixture.

[0048] In step (3), the curing agent DDM is added to the transparent liquid resin mixture obtained in step (2), stirred and dissolved at 130±5° C. to obtain a liquid molding resin.

[0049] In step (4), the liquid molding resin obtained in step (3) is heated to the minimum viscosity temperature of the resin (120° C.), and vacuumized to eliminate air bubbles in the resin. The above-mentioned liquid molding resin was heated up to 180°C, and cured for 2 hours to obtain a resin cast body, which w...

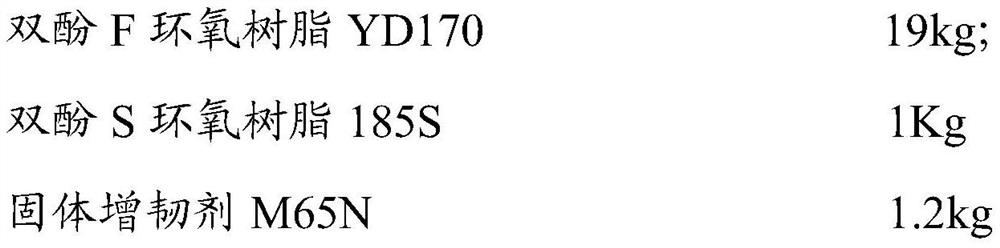

Embodiment 2

[0054] Step (1) weigh each component as required;

[0055]

[0056]

[0057] Among them, the solid toughening agent M65N is methyl methacrylate-butyl acrylate-methyl methacrylate triblock copolymer.

[0058] Step (2) Mix the liquid thermosetting resin with the solid toughening agent M65N at room temperature, and heat up while stirring, and dissolve at 130±5°C, and stir for 120 minutes until the solid toughening agent M65N is completely dissolved to obtain a liquid Resin transparent mixture.

[0059] Step (3) adding the curing agent DDS into the transparent liquid resin mixture obtained in step (2), stirring and dissolving at 130±5° C. to obtain a liquid molding resin.

[0060] Step (4) Heat the liquid molding resin obtained in step (3) to the minimum viscosity temperature of the resin (120°C), and then vacuumize to eliminate the air bubbles in the resin. The above-mentioned liquid molding resin was heated up to 180°C, and cured for 2 hours to obtain a resin cast body, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com