Continuous casting covering slag for high-titanium steel and preparation method of continuous casting covering slag

A continuous casting mold flux and high-titanium technology, applied in the metallurgical field, can solve the problems of thickening of the sintered layer, restricting the application field of high-titanium steel, performance deterioration, etc., and achieve the effect of reducing CaO content, good internal quality, and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention provides a method for preparing the continuous casting slag for high-titanium steel described in the above technical solution, comprising:

[0039] Bauxite, alumina, barium carbonate, barium fluoride, fluorite, quartz sand, lithium carbonate and carbonaceous materials are prepared to obtain continuous casting mold flux for high titanium steel.

[0040] In the present invention, Al in the bauxite 2 o 3 The mass content of preferably>77%.

[0041] In the present invention, the alumina is preferably alumina for electrolytic aluminum; Al in the alumina 2 o 3 The mass content of preferably>77%.

[0042] In the present invention, the BaCO in the barium carbonate 3 The mass content of preferably >96%, the BaF in the barium fluoride 2 The mass content of preferably>96%, the CaF in the fluorite 2 The mass content of preferably>86%, SiO in the quartz sand 2 The mass content of preferably>92%, Li in the lithium carbonate 2 CO 3 The mass content of C...

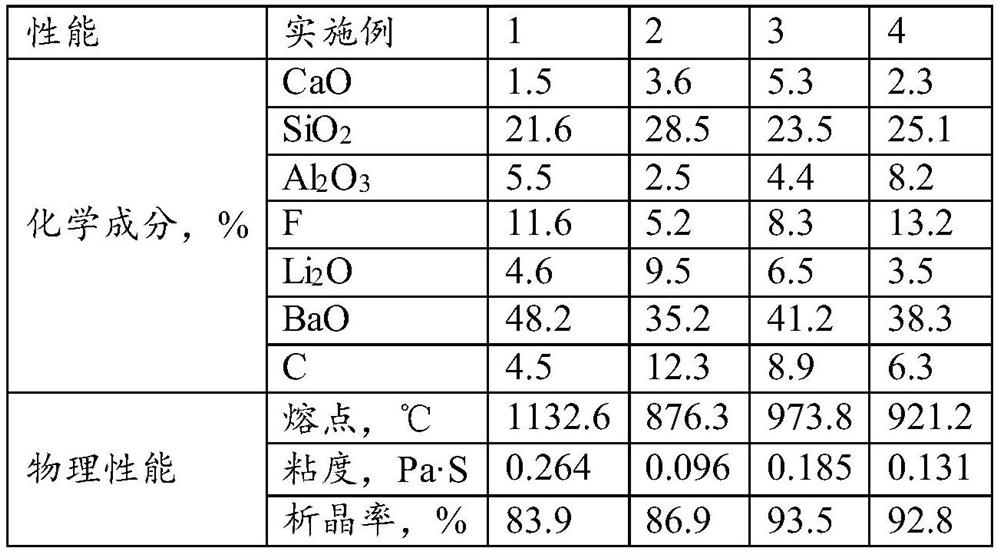

Embodiment 1~4

[0070] Mix bauxite and electrolytic aluminum with alumina, barium carbonate, barium fluoride, fluorite, quartz sand, lithium carbonate and carbonaceous materials and then grind them to obtain powders with a particle size of 1 mm to 5 mm; after stirring and mixing , then add 10-20% of water, then stir until uniform, then pelletize and dry, put the dried ball into an induction furnace to smelt until the ball is completely melted into a liquid state, then cool, dry, and crush (after crushing Particle size is less than 5mm) to obtain mold slag premelt, and then prepared according to the conventional process of mold slag, crush the premelt to less than 200 mesh, add carbonaceous materials and put them into the fine mill together, and mix with 1 times Water (the quality of water is 1 times of the quality of premelt material), 1.6% cellulose binder (the quality of cellulose binder is 1.6% of the quality of premelt material), and the slurry obtained after fine grinding for 50 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| crystallization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com