Impregnatable high-density, brittle material structure

A brittle material and brittle technology, applied in the field of new structures, can solve the problems of low heat resistance temperature, inability to withstand the sintering temperature of oxide ceramics, oxidizing atmosphere, etc., and achieve high crystallinity, excellent wettability, and contact angle. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

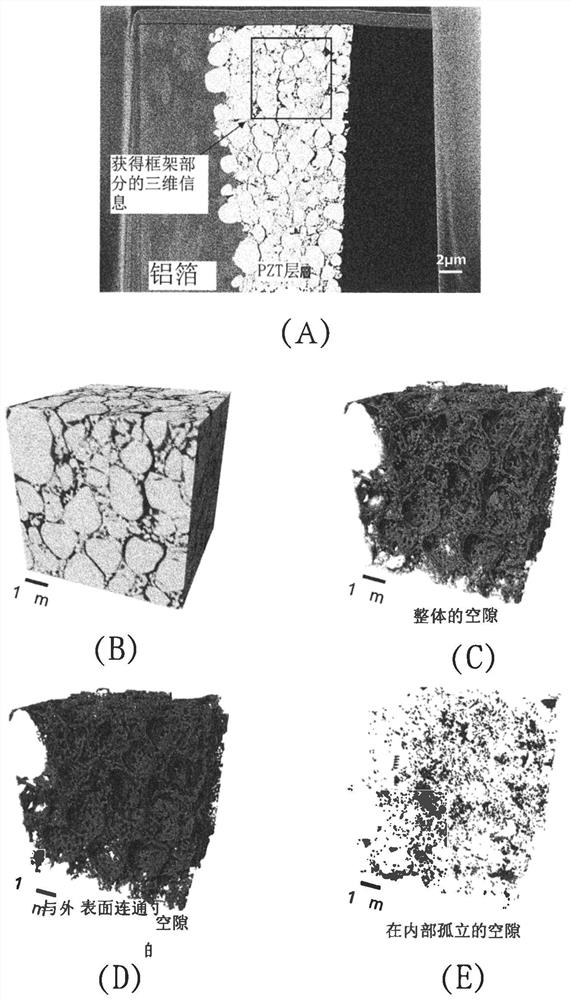

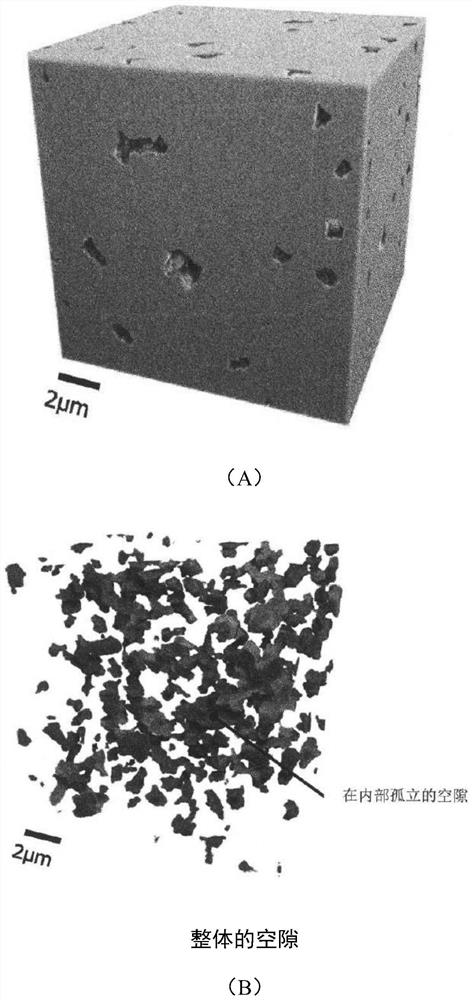

[0091] Void structure of highly dense condensed film using PZT particles

[0092] Next, a specific manufacturing method of the structure of the present invention will be described.

[0093] PZT particles (average particle shape: 1550 nm) serving as first particles adhered to the surface of stainless steel SUS304 (film thickness: 20 μm).

[0094] The first PZT particles were synthesized by the molten salt method using PZT-LQ powder manufactured by Sakai Chemical Industries. The first PZT particles were weighed using a microanalytical balance (SHIMADZU, model: AEM-5200), moved to a 50cc glass container filled with ethanol, and ultrasonicated at 350W and 20kHz using an ultrasonic homogenizer (manufactured by SONIC & MATERIALS, model: VCX750). After dispersing for 1 minute, the solution was transferred to an air brush coating system (manufactured by GSI Creos, PS311 air brush kit), and sprayed on the SUS304 of the transfer plate prepared in advance on a hot plate set at 60°C. T...

Embodiment 2

[0134] Physical properties of a highly dense cohesive film using PZT particles

[0135] Next, the leakage current characteristics and polarization characteristics of the highly dense aggregate film of the present invention were investigated.

[0136] In order to evaluate electrical physical properties, an Au electrode having an area of 0.5 mm×0.5 mm and a thickness of 400 nm was deposited on the surface of each PZT by a sputtering method. Figure 6 It shows the leakage current characteristics of a PZT compact film with a porosity of about 35% impregnated with silicone oil, and the change in leakage current characteristics before and after silicone oil impregnation of a PZT highly dense cohesive film with a porosity of 11% to 15%. , A diagram showing leakage current characteristics of a PZT highly dense condensed film impregnated with silicone oil and having a porosity of about 10% or less.

[0137] In a normal compressed powder with a porosity of about 35%, even if the sil...

Embodiment 3

[0141] Lamination of highly dense aggregates sandwiched between electrode layers ( Figure 8 )

[0142] (1) Manufacture of Unit 1

[0143] PZT particles (average particle shape: 1550 nm) serving as first particles adhered to the surface of SUS304 (film thickness: 20 μm).

[0144] The first PZT particles were synthesized by the molten salt method using PZT-LQ powder manufactured by Sakai Chemical Industries. Weigh the first PZT particles with a micro-analytical balance (SHIMADZU, model: AEM-5200), move to a 50cc glass container with ethanol, and use an ultrasonic homogenizer (manufactured by SONIC & MATERIALS, model: VCX750) with 350W, 20kHz ultrasonic waves After dispersing for 1 minute, the solution was transferred to an air brush coating system (manufactured by GSI Creos, PS311 air brush kit), and sprayed on the SUS304 of the transfer plate prepared in advance on a hot plate set at 60°C. This attaches the first PZT particles to the SUS304 surface.

[0145] The second pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com