Surface modification method for polytetrafluoroethylene product

A technology of polytetrafluoroethylene and surface modification, applied in the direction of coating, etc., can solve problems such as conditions and processes that are difficult to determine, and achieve the effect of increasing wettability and adhesion and facilitating penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

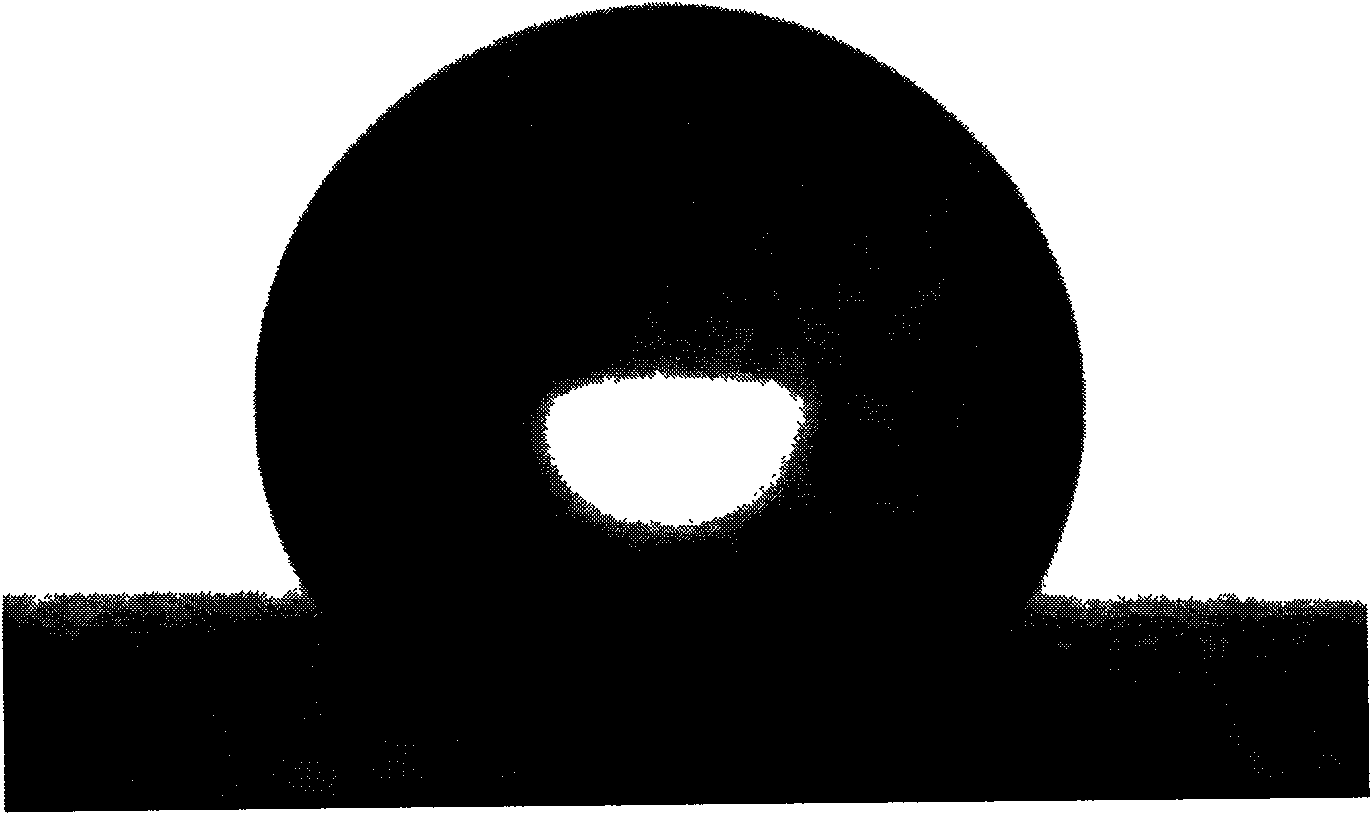

[0025] The PTFE oil seal sheet to be treated is immersed in polyethylene glycol with a molecular weight of 400, soaked at room temperature for 3 hours, and then taken out, and then put into a plasma generator, and plasma surface modification is performed in the plasma atmosphere. The treatment power is 200W, the treatment time is 15 minutes, and then washed with deionized water to remove polyethylene glycol that is not grafted on PTFE, and dried to obtain a surface-modified PTFE sealing sheet. The measured contact angle of the surface-modified PTFE oil seal is 56°, such as figure 2 Shown.

Embodiment 2

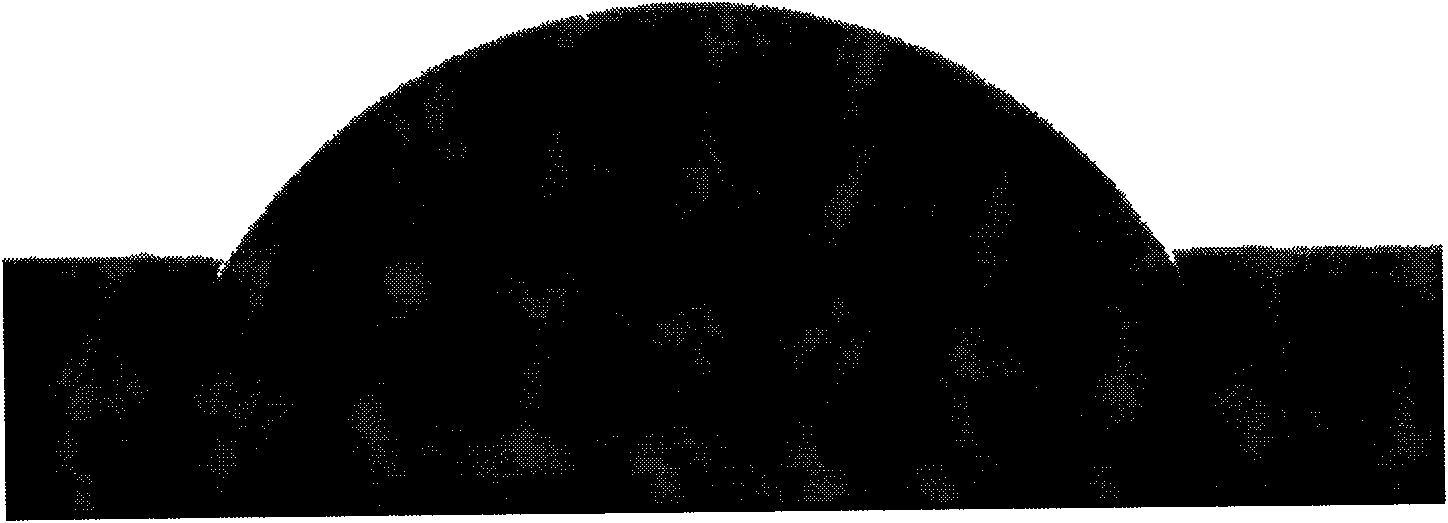

[0027] The PTFE oil seal sheet to be processed is immersed in polyethylene glycol with a molecular weight of 2000, soaked at 80°C for 5 hours and then taken out, and then put into the plasma generator, and plasma surface is performed in the plasma atmosphere area Modification, the treatment power is 300W, the treatment time is 20 minutes, and then washed with water to remove polyethylene glycol not grafted on the polytetrafluoroethylene, and dried to obtain a surface-modified polytetrafluoroethylene oil seal sheet. The contact angle of the surface-modified polytetrafluoroethylene oil seal was 82°.

Embodiment 3

[0029] The polytetrafluoroethylene oil seal sheet to be treated is immersed in an aqueous solution of polyethylene glycol, wherein the molecular weight of polyethylene glycol is 8000, and the concentration of polyethylene glycol is 80%; after soaking at room temperature for 4 hours, take it out and dry at 80°C. The solvent is dry removed, and then it is introduced into the plasma atmosphere area for plasma surface modification. The treatment power is 150W, the treatment time is 30 minutes, and then washed with water to remove polyethylene glycol not grafted on the polytetrafluoroethylene, and dried to obtain a surface-modified polytetrafluoroethylene oil seal sheet. The contact angle of the surface-modified polytetrafluoroethylene oil seal was 71°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com