Preparation method for surface ionization modified polysulfone ultrafiltration membrane

A polysulfone ultrafiltration membrane and ionization technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of increased water flux, reduced membrane flux, and power consumption of blended ultrafiltration membranes Advanced problems, to achieve the effect of reduced contact angle, long-lasting hydrophilicity, and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

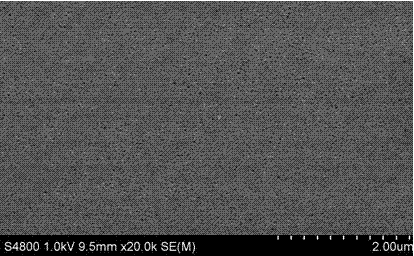

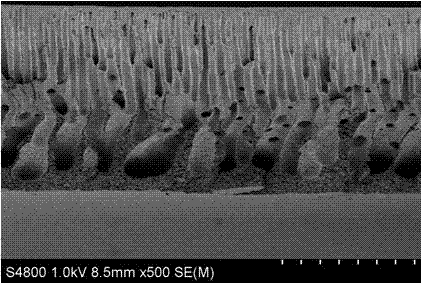

Embodiment 1

[0043] The weight average molecular weight is 2.5×10 5 The polysulfone (15wt%), the weight average molecular weight is 2×10 5 Polydimethylaminoethyl methacrylate-polysulfone-polydimethylaminoethyl methacrylate triblock copolymer (5wt%) blended with N,N-dimethylacetamide (80wt%), in Stir at 40°C for 36 hours, filter, vacuum degassing, and obtain the casting solution; the casting solution at 30°C passes through a hollow fiber spinning machine to obtain a polysulfone hollow fiber membrane, in which the internal coagulation bath is H 2 O, the temperature is 50°C; the external coagulation bath is H 2 O, the temperature is 40°C, and the dry section distance is 10cm; the obtained polysulfone hollow fiber membrane is immersed in a solution composed of 3-bromopropionic acid (30wt%) and ethanol (70wt%) at 30°C for surface quaternization Treatment, the reaction time is 24 hours; the obtained polysulfone ultrafiltration membrane is washed with 20° C. deionized water for 24 hours, and va...

Embodiment 2

[0045] The weight average molecular weight is 1.0×10 5 The polysulfone (20wt%), the weight average molecular weight is 2×10 4 Polydimethylaminoethyl methacrylate-polysulfone-polydimethylaminoethyl methacrylate triblock copolymer (10wt%) blended with N,N-dimethylformamide (70wt%), in Stir at 60°C for 24 hours, filter and vacuum defoam to obtain the casting solution; the casting solution at 40°C passes through a flat film forming machine with a scraper gap of 50 μm, and the coagulation bath is DMAC / H 2 O (30wt%) mixed solution, the exposure time is 5s, obtains polysulfone flat ultrafiltration membrane; The polysulfone flat ultrafiltration membrane that obtains is immersed in the solution that 5-bromovaleric acid (15wt%) and ethanol (85wt%) form The surface quaternization treatment was carried out at 50°C, and the reaction time was 36 hours; the obtained polysulfone ultrafiltration membrane was washed with 30°C deionized water for 24 hours, and vacuum-dried at 60°C for 8 hours t...

Embodiment 3

[0047] The weight average molecular weight is 5.0×10 5 The polysulfone (10wt%), the weight average molecular weight is 1×10 5 The polydimethylaminoethyl methacrylate-polysulfone-polydimethylaminoethyl methacrylate triblock copolymer (3wt%) was blended with N-methylpyrrolidone (87wt%) and stirred at 90°C For 20 hours, filter, vacuum degassing, and obtain the casting solution; the casting solution at 80°C passes through a flat film forming machine with a scraper gap of 150 μm, and the coagulation bath is H 2 O, and the exposure time was 30s to obtain a polysulfone flat ultrafiltration membrane; the obtained polysulfone flat ultrafiltration membrane was immersed in a solution composed of 3-bromovaleric acid (3wt%) and ethanol (97wt%) at 70 ° C. The surface is quaternized, and the reaction time is 72 hours; the obtained ultrafiltration membrane is washed with 50° C. deionized water for 12 hours, and vacuum-dried for 48 hours to obtain a surface ionized polysulfone ultrafiltration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com