Flexible neutral zinc air battery and preparation method thereof

A zinc-air battery, neutral technology, applied in the direction of battery electrodes, fuel cell half-cells and primary battery-type half-cells, circuits, etc., can solve the problem of lack of flexible neutral zinc-air batteries, etc., to achieve enhanced conductivity , low price, high oxygen reduction catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A flexible neutral zinc-air battery prepared by the following method:

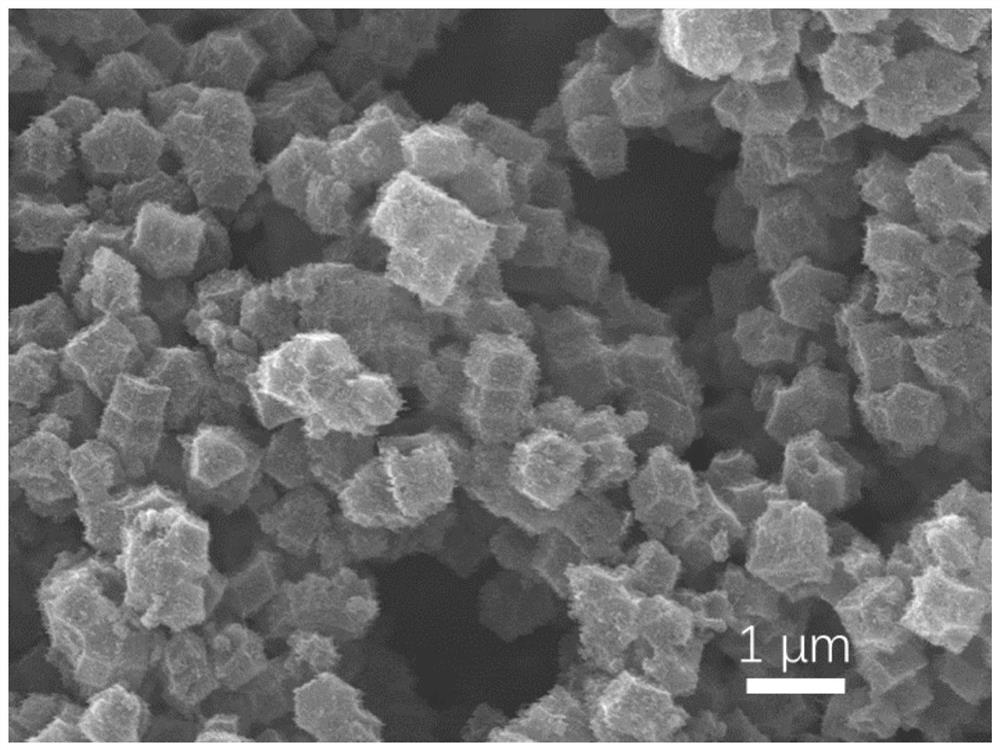

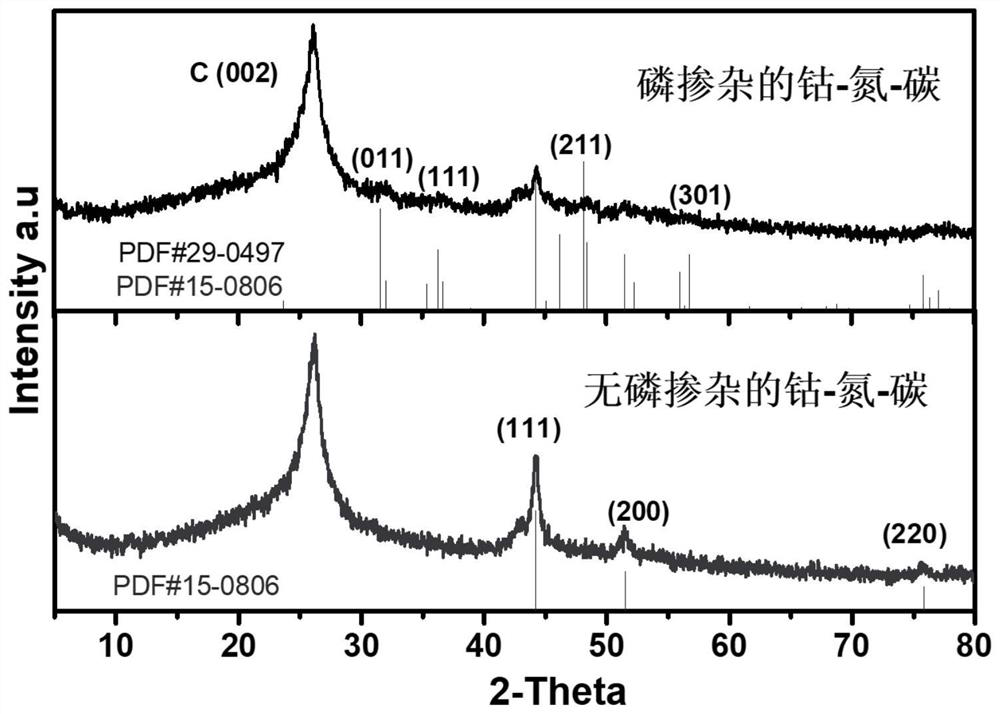

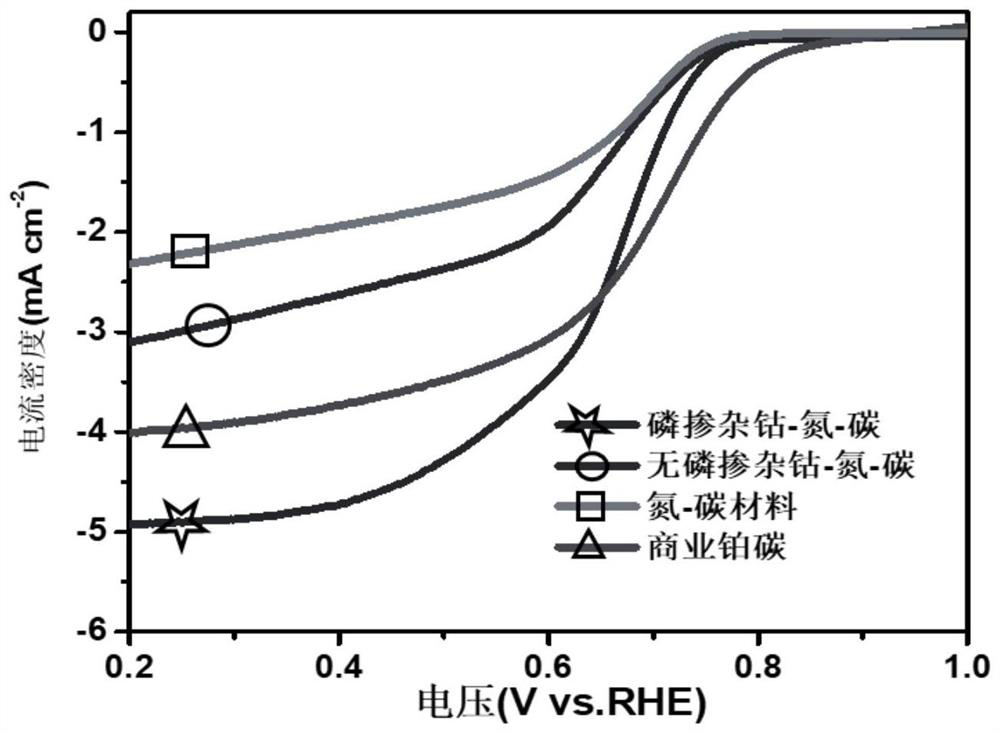

[0043] (1) ZIF8@ZIF67 was annealed in a tube furnace under an argon atmosphere, and black powder was obtained after holding at 500°C for 3 hours. 0.5M H 2 SO 4 Soak the black powder in the solution for 24 hours to remove excess cobalt species, and dry it to be tested. Weigh an appropriate amount of dried black powder and place it in porcelain boat 1, weigh 1g of sodium hypophosphite and place it in porcelain boat 2, place porcelain boats 1 and 2 in front and back, and pyrolyze sodium hypophosphite in a tube furnace at 500°C for phosphorus Doping to obtain phosphorous doped cobalt nitrogen carbon.

[0044](2) Put 3g of PVA in 24ml of water, heat in an oil bath at 90°C, stir and mix evenly, and stir continuously for 1.5h; weigh 3.8g of ammonium chloride and 1.34g of potassium chloride and dissolve them in 6ml of water to obtain a salt solution, and put the salt solution into In the PVA aqueous sol...

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is that the non-metal atom doped in step (1) is nitrogen, specifically as follows:

[0048] (1) The obtained purple powder was annealed in a tube furnace under an argon atmosphere, and black powder was obtained after holding at 500° C. for 3 h. 0.5M H 2 SO 4 Soak the black powder in the solution for 24 hours to remove excess cobalt species, and dry it to be tested. Weigh an appropriate amount of dried black powder and place it in porcelain boat 1, weigh 1g of urea and place it in porcelain boat 2, place porcelain boats 1 and 2 in front and back, and pyrolyze urea in a tube furnace at 350°C for nitrogen doping to obtain nitrogen doped Miscellaneous cobalt nitrogen carbon.

Embodiment 3

[0050] The difference between this embodiment and embodiment 1 is that the non-metal atom doped in step (1) is sulfur, specifically as follows:

[0051] (1) The obtained purple powder was annealed in a tube furnace under an argon atmosphere, and black powder was obtained after holding at 500° C. for 3 h. 0.5M H 2 SO 4 Soak the black powder in the solution for 24 hours to remove excess cobalt species, and dry it to be tested. Weigh an appropriate amount of dried black powder and place it in porcelain boat 1, weigh 1 g of thiourea and place it in porcelain boat 2, place porcelain boats 1 and 2 back and forth, pyrolyze thiourea in a tube furnace at 350°C for sulfur doping, and obtain Sulfur-doped cobalt nitrogen carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com