Ceramic ball fired plate and preparation method thereof

A technology of ceramic balls and sintered plates, applied in the field of kiln furniture, can solve the problems such as no mature L-shaped plate technology, poor thermal shock resistance, short service life, etc., and achieve optimized reuse, good high temperature strength, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

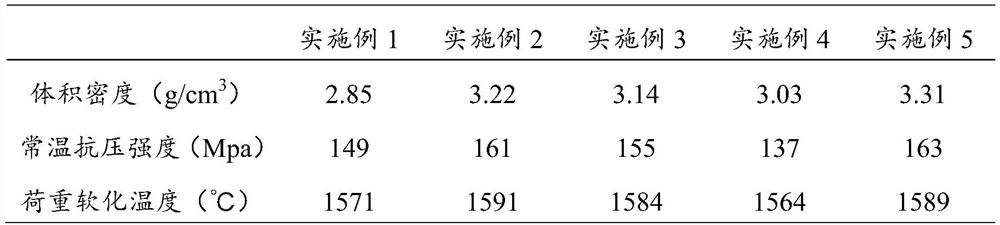

Examples

preparation example Construction

[0045] Correspondingly, the present invention also provides a method for preparing the above ceramic ball fired plate, comprising the following steps:

[0046] S1. Ingredients ball milling: grind and sieve ceramic roller waste, zirconium-aluminum brick waste, waste aluminum powder, and kaolin into the ball mill according to the proportion, add dispersant and binder and mix evenly. Grinding down to obtain slurry;

[0047] S2. Drying and granulating: drying and granulating the slurry to obtain granular powder;

[0048] S3. Compression molding: pour the powder into an L-shaped mold after being mixed with the binder solution, pressurize and dry to obtain a rough billet;

[0049] S4. Firing at high temperature: sending the rough billet to a kiln for firing to obtain a ceramic ball fired board product.

[0050] The preparation method of a ceramic ball firing plate provided by the present invention comprises four steps of batching ball milling, drying and granulation, film molding,...

Embodiment 1

[0063] Sintered ceramic ball plate and its preparation method,

[0064] The raw material formula of the ceramic ball firing board is (according to mass fraction): 40% of ceramic roller bar waste, 15% of zirconium-aluminum brick waste, 20% of waste aluminum powder, 24% of kaolin, 0.4% of dispersant and 0.6% of binder %.

[0065] The preparation method of the above-mentioned fired ceramic ball plate comprises the following steps:

[0066] S1: According to the mass fraction ratio, grind 40% of ceramic roller waste, 15% of zirconium-aluminum brick waste, 20% of waste aluminum powder, and 24% of kaolin, pass through an 80-mesh screen, and then add to the ball mill, and add 0.4wt to the ball mill % of dispersant and 0.1wt% of binder, ground under the condition of ball water ratio of 1.2:2:1 to obtain a slurry with particle size D50 of 55 μm.

[0067] S2. Send the slurry to the spray drying tower for granulation. The temperature of the main tower is 568°C, and the moisture content ...

Embodiment 2

[0071] The raw material formula of the ceramic ball fired board is (according to mass fraction): 46% of ceramic roller bar waste, 13% of zirconium-aluminum brick waste, 18% of waste aluminum powder, 22% of kaolin, 0.52% of dispersant and 0.48% of binder %.

[0072] The preparation method of the above-mentioned fired ceramic ball plate comprises the following steps:

[0073]S1: According to the mass fraction ratio, crush 46% of ceramic roller rod waste, 13% of zirconium-aluminum brick waste, 18% of waste aluminum powder, and 22% of kaolin, pass it through a 80-mesh screen, and then add it to the ball mill, and add 0.52wt to the ball mill % dispersant and 0.1wt% binder, and grind under the condition that the ball-to-water ratio is 1:2:1 to obtain a slurry with a particle size D50 of 64 μm.

[0074] S2. Send the slurry to the spray drying tower for granulation. The temperature of the main tower is 571° C., and the moisture content of the granulated particles is 0.8 wt%.

[0075...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com