High-strength alloy material

A high-strength alloy and silicate technology, applied in the field of alloys, can solve the problems affecting the wear resistance and service life of cutting tools and drill materials, cutting tumors and crater wear, etc., to achieve increased hardness, good wear resistance, good The effect of high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

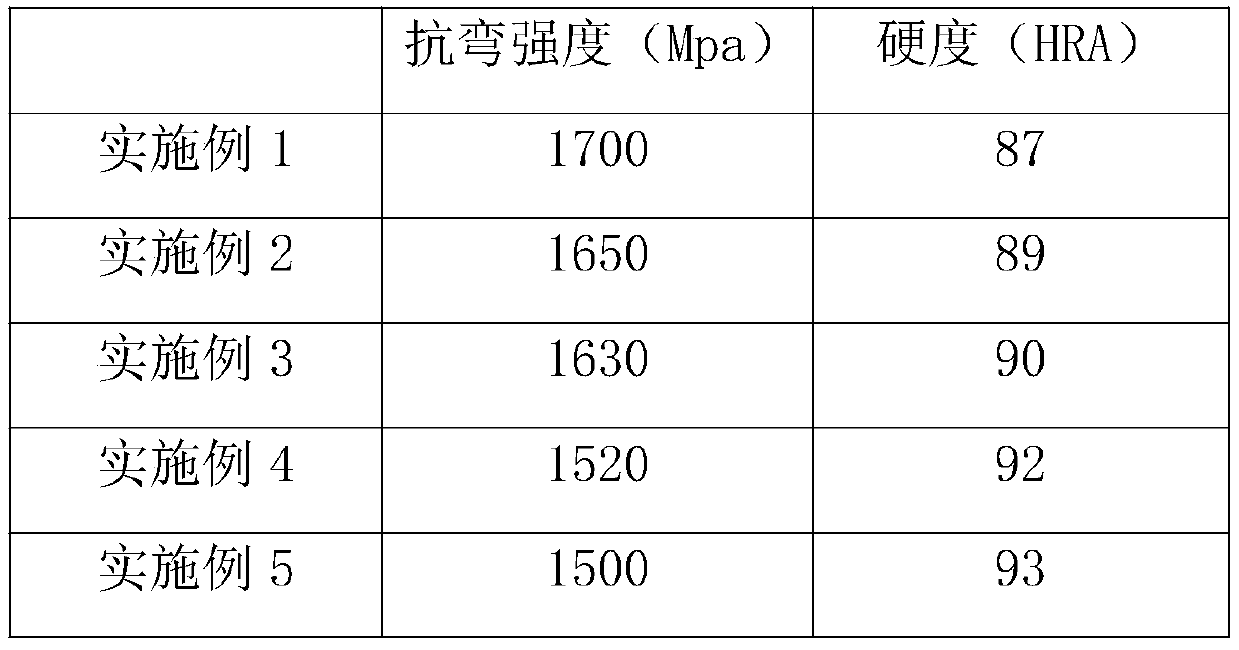

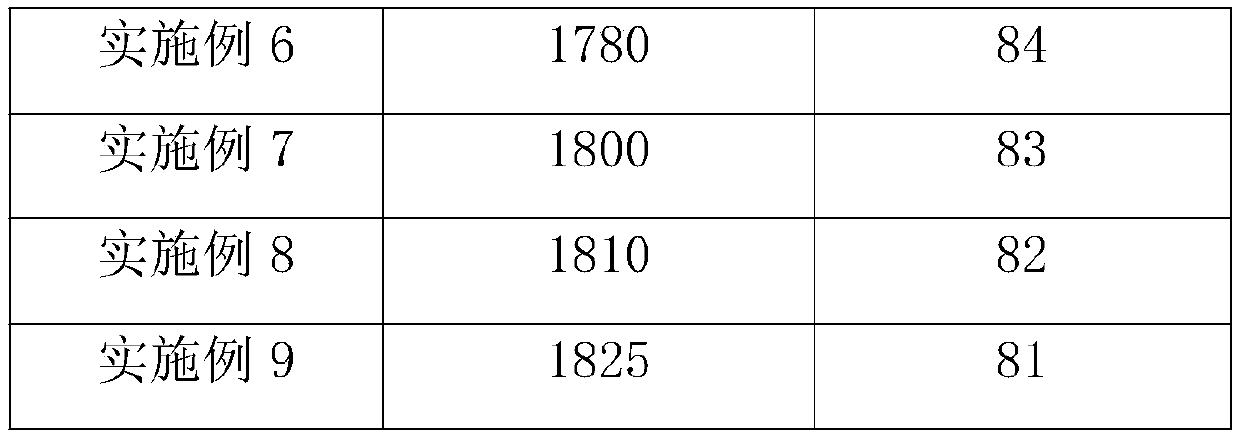

Examples

Embodiment 1

[0040] 0.5 parts of manganese, 2 parts of molybdenum, 1 part of chromium, 5 parts of nickel, 11 parts of carbon, 15 parts of iron, 12 parts of silicate, 7 parts of barium hydroxide, 6 parts of tungsten carbide with a particle size of 0.7 microns Proportioning to form raw materials;

[0041] Carry out wet grinding on raw materials, add industrial alcohol as wet grinding medium during wet grinding, wet grinding time is 20 hours, wet grinding ball material ratio is 4:1, obtain slurry and dry;

[0042] Add glue to the dried powder and press it into shape;

[0043] Carry out sintering, the sintering temperature is 1300° C., and the sintering time is 1 hour to obtain an alloy.

Embodiment 2

[0045] 1 part of manganese, 4 parts of molybdenum, 2 parts of chromium, 7 parts of nickel, 13 parts of carbon, 20 parts of iron, 15 parts of silicate, 10 parts of barium hydroxide, 8 parts of tungsten carbide with a particle size of 0.9 microns Proportioning to form raw materials;

[0046] Carry out wet grinding on raw materials, add industrial alcohol as wet grinding medium during wet grinding, wet grinding time is 30 hours, wet grinding ball material ratio is 4:1, obtain slurry and dry;

[0047] Add glue to the dried powder and press it into shape;

[0048] Carry out sintering, the sintering temperature is 1450° C., the sintering time is 3 hours, and the alloy is obtained.

Embodiment 3

[0050] 0.6 parts of manganese, 3 parts of molybdenum, 1.5 parts of chromium, 6 parts of nickel, 12 parts of carbon, 17 parts of iron, 13 parts of silicate, 8 parts of barium hydroxide, and 7 parts of tungsten carbide with a particle size of 0.8 microns Proportioning to form raw materials;

[0051] Carry out wet grinding on raw materials, add industrial alcohol as wet grinding medium during wet grinding, wet grinding time is 25 hours, wet grinding ball material ratio is 4:1, obtain slurry and dry;

[0052] Add glue to the dried powder and press it into shape;

[0053] Carry out sintering, the sintering temperature is 1400° C., and the sintering time is 2 hours to obtain an alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com