Corrosive agent for displaying TC4 metallographic structure and preparation method and use method

A metallographic structure display and metallographic structure technology, applied in the field of TC4 metallographic structure display etchant and preparation, can solve the problems that the metallographic structure cannot be displayed, and the α grain size cannot be measured, so as to improve the measurement accuracy and rating accuracy degree, accurate organization rating, and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

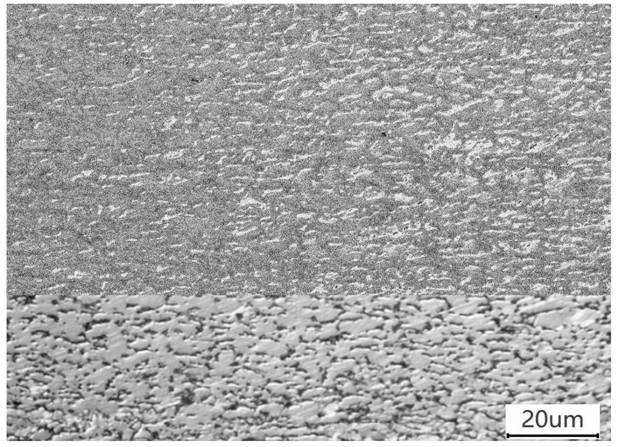

Embodiment 1

[0037] (1) A kind of preparation of etchant for TC4 metallographic structure display, concrete steps are as follows:

[0038] Prepare metallographic structure etchant: first, prepare saturated oxalic acid aqueous solution (50%), at room temperature, measure the deionized water of 500ml and join in the glass beaker of 1000ml, weigh the analysis pure oxalic acid crystal of 250g, then while stirring Slowly add it to the beaker, stir well, then place it until the solution is clear and ready for use;

[0039] Then, at room temperature, measure 35ml of deionized water and 30ml of the supernatant of saturated oxalic acid aqueous solution with a graduated cylinder, then pour them into a 100ml beaker in turn, stir evenly, and then absorb 5ml of hydrofluoric acid and 5ml of nitric acid with a Basset pipette. Slowly add it into a beaker, stir to make it evenly mixed, and obtain the metallographic structure etchant.

[0040] (2) The method of using the above-mentioned corrosive agent, th...

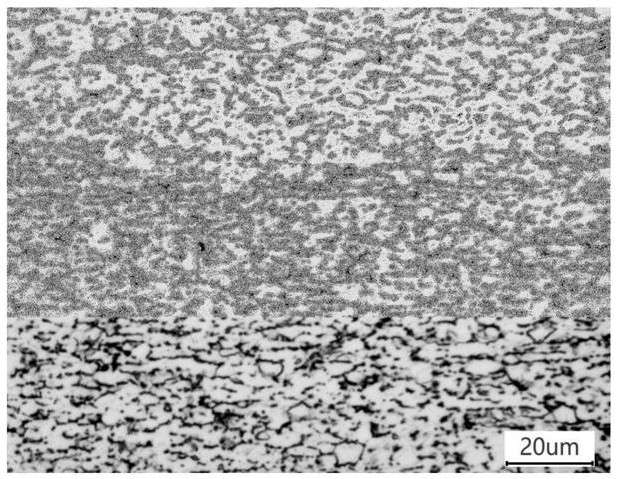

Embodiment 2

[0070] (1) A kind of preparation of etchant for TC4 metallographic structure display, concrete steps are as follows:

[0071] Prepare metallographic structure etchant: first, prepare saturated oxalic acid aqueous solution (50%), at room temperature, measure the deionized water of 500ml and join in the glass beaker of 1000ml, weigh the analysis pure oxalic acid crystal of 250g, then stir while Slowly add to the beaker, stir well, then place until the solution is clear and ready for use;

[0072] Then, at room temperature, measure 40ml of deionized water and 28ml of supernatant of saturated oxalic acid aqueous solution with a graduated cylinder, then pour them into a 100ml beaker in turn, stir evenly, and then absorb 8ml of hydrofluoric acid and 8ml of nitric acid respectively with a Basset pipette. Slowly add it into a beaker, stir to make it evenly mixed, and obtain the metallographic structure etchant.

[0073] (2) The method of using the above-mentioned corrosive agent, the...

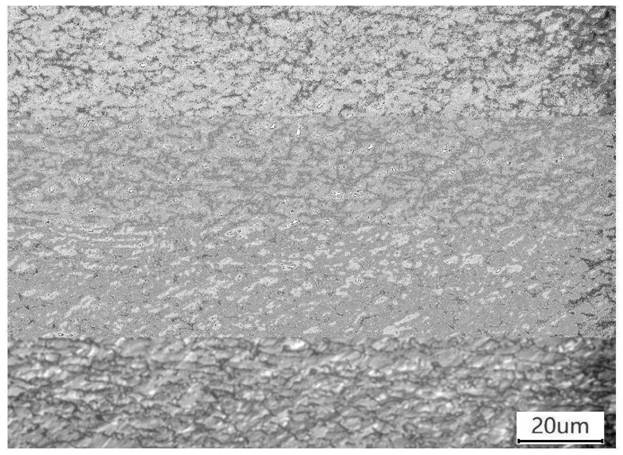

Embodiment 3

[0081] (1) A kind of preparation of etchant for TC4 metallographic structure display, concrete steps are as follows:

[0082] Prepare metallographic structure etchant: first, prepare saturated oxalic acid aqueous solution (50%), at room temperature, measure the deionized water of 500ml and join in the glass beaker of 1000ml, weigh the analysis pure oxalic acid crystal of 250g, then stir while Slowly add to the beaker, stir well, then place until the solution is clear and ready for use;

[0083] Then, at room temperature, measure 45ml of deionized water and 38ml of supernatant of saturated oxalic acid aqueous solution with a graduated cylinder, and then pour them into a 100ml beaker in turn and stir evenly; draw 5ml of sulfuric acid with a Basset pipette, stir the solution and slowly Add it into the beaker, stir it evenly, and let it stand for 10 minutes; then use a Basset pipette to absorb 10ml of hydrofluoric acid and 10ml of nitric acid, slowly add it to the beaker in turn, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com