Baking varnish for magnesium aluminum alloy base material and preparation and using methods thereof

A magnesium-aluminum alloy and baking paint technology, applied in the field of baking paint, can solve the problems of road antifreeze salt comprehensive corrosion, non-conductive film layer, and difficult coating, so as to save time, manpower and material resources, simple construction process, and reduce pretreatment process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

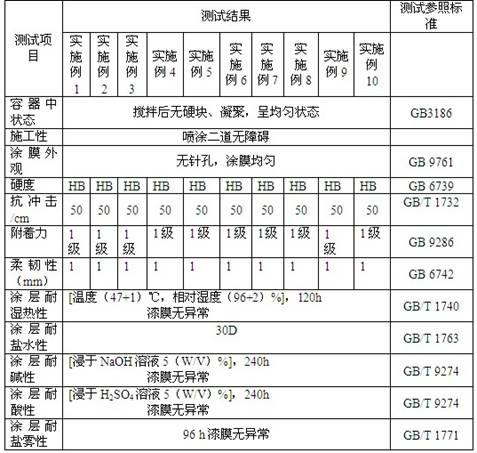

Examples

Embodiment 1

[0038] The steps of the method for preparing the baking varnish for the magnesium-aluminum alloy base material are as follows:

[0039] (1) Add 10 grams of polyester modified acrylic resin, 8 grams of epoxy resin, 0.3 grams of defoamer, 0.3 grams of dispersant, 0.1 grams of wetting agent, 0.3 grams of leveling agent, and 2 grams of solvent into the stirring In the kettle, under the condition of 400r / min rotating speed, stir for 5 minutes;

[0040] (2) Add 28 grams of color paste, 20 grams of fillers, and 0.5 grams of anti-settling agent, and stir and disperse at high speed for 30 minutes at a speed of 800 r / min;

[0041] (3) Finally, add 3 grams of amino resin, 8.5 grams of adhesion promoter, and 1 gram of solvent, and stir for 20 minutes at a speed of 400 r / min to complete the preparation process of the polyester baking varnish.

[0042] The method of using the polyester baking varnish for the magnesium-aluminum alloy base material prepared in this example is: weigh the poly...

Embodiment 2

[0045] The steps of the method for preparing the baking varnish for the magnesium-aluminum alloy base material are as follows:

[0046] (1) Add 11 grams of polyester modified acrylic resin, 8.2 grams of epoxy resin, 0.32 grams of defoamer, 0.32 grams of dispersant, 0.12 grams of wetting agent, 0.32 grams of leveling agent, and 2.15 grams of solvent into the stirring In the kettle, under the condition of 440r / min rotating speed, stir for 5 minutes;

[0047] (2) Add 28.7 grams of color paste, 20.5 grams of fillers, and 0.57 grams of anti-settling agent, and stir and disperse at high speed for 31 minutes at a speed of 840r / min;

[0048] (3) Finally, add 3.2 grams of amino resin, 8.75 grams of adhesion promoter, and 1.15 grams of solvent, and stir for 21 minutes at a speed of 420 r / min to complete the preparation process of the polyester baking varnish. The method of using the polyester baking varnish for the magnesium-aluminum alloy base material prepared in this example is: wei...

Embodiment 3

[0051] The steps of the method for preparing the baking varnish for the magnesium-aluminum alloy base material are as follows:

[0052] (1) Add 12 grams of polyester modified acrylic resin, 8.4 grams of epoxy resin, 0.34 grams of defoamer, 0.34 grams of dispersant, 0.14 grams of wetting agent, 0.34 grams of leveling agent, and 2.3 grams of solvent into the stirring In the kettle, under the condition of 480r / min rotating speed, stir for 6 minutes;

[0053] (2) Add 29.4 grams of color paste, 21 grams of fillers, and 0.64 grams of anti-settling agent, and stir and disperse at high speed for 32 minutes at a speed of 880 r / min;

[0054] (3) Finally, add 3.4 grams of amino resin, 9 grams of adhesion promoter, and 1.3 grams of solvent, and stir for 22 minutes at a speed of 440 r / min to complete the preparation process of the polyester baking varnish. The method of using the polyester baking varnish for the magnesium-aluminum alloy base material prepared in this example is: weigh the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com