Preparation method of nano titanium dioxide

A nano-titanium dioxide and nano-titanium technology, applied in titanium dioxide, titanium oxide/hydroxide, nanotechnology and other directions, can solve the problems of easy coagulation, agglomeration, large surface activity, and coagulation of nanoparticles, and achieve excellent photocatalytic activity. , the technical route is simple, the effect of easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] First, titanium dioxide powder was dispersed in 10 moles per liter of sodium hydroxide solution at a mass ratio of 1:50, and then the solution was transferred to a hydrothermal kettle and kept at 120 degrees Celsius for 24 hours to obtain sodium titanate nanotubes. Subsequently, the sodium titanate nanotubes obtained above were separated and washed, then put into 0.05 mole per liter of hydrochloric acid solution for hydrogen ion exchange for 2 hours, and then separated and dried to obtain one-dimensional structure nano titanate powder. Subsequently, the 25 percent hydrochloric acid solution and the one-dimensional structure nano titanic acid powder were mixed evenly according to the mass ratio of 0.25 to 1, and then put into the reaction kettle and sealed. Finally, the above reaction kettle was put into an oven and heated at 140 degrees Celsius for 16 hours to obtain a nano-titanium dioxide product.

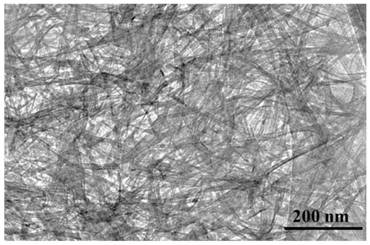

[0042] figure 1 One-dimensional structure nano titanate nanotubes we...

Embodiment 2

[0051] First, disperse titanium dioxide powder in 5 moles per liter of sodium hydroxide solution at a mass ratio of 1 to 100, and then transfer the solution to a hydrothermal kettle at a constant temperature of 200 degrees Celsius for 24 hours to obtain a one-dimensional structure of nano titanic acid sodium. Subsequently, the sodium titanate obtained above was separated and washed, and then put into a 0.01 mole per liter hydrochloric acid solution for hydrogen ion exchange for 2 hours, and then separated and dried to obtain a one-dimensional structure nano titanate powder. Subsequently, mix the 10 percent hydrochloric acid solution and the one-dimensional structure nano titanic acid powder according to the mass ratio of 0.8 to 1, and then put it into the reaction kettle and seal it. Finally, the reaction kettle was put into a microwave oven, and microwaved at 160 degrees Celsius for 2 hours to obtain a nano-titanium dioxide product.

[0052] In Example 2, the nano titanic ac...

Embodiment 3

[0055] First, disperse titanium dioxide powder in 15 moles per liter of sodium hydroxide solution at a mass ratio of 1 to 20, and then transfer the solution to a hydrothermal kettle at a constant temperature of 150 degrees Celsius for 24 hours to obtain a one-dimensional structure of nano titanic acid sodium. Subsequently, the one-dimensional structure nano sodium titanate obtained above was separated and washed, and then put into 0.1 mole per liter of hydrochloric acid solution for hydrogen ion exchange for 6 hours, and then separated and dried to obtain one-dimensional structure nano titanate powder. Subsequently, mix the 20% hydrochloric acid solution and the one-dimensional structure nano titanic acid powder according to the mass ratio of 0.4 to 1, and then put it into the reaction kettle and seal it. Finally, the above reactor was put into an oil bath, and heated at 180 degrees Celsius for 10 hours to obtain a nano-titanium dioxide product.

[0056] In Example 3, the nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com