Preparation method of low-melting-point alloy phase change material

A technology of alloy phase and low melting point, which is applied in the field of preparation of low melting point alloy phase change materials, can solve the problems of reducing the volume of phase change materials, easy to be oxidized, insufficient alloying, etc., to achieve increased heat capacity, convenient operation, and reduced volume The effect of proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

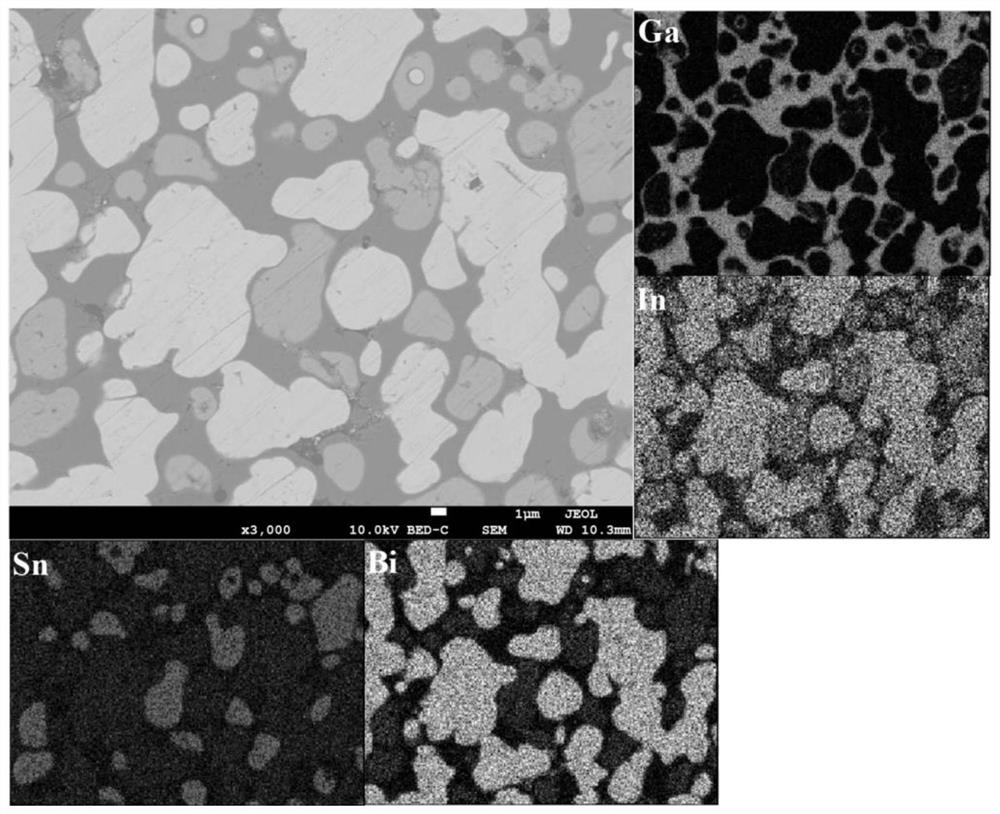

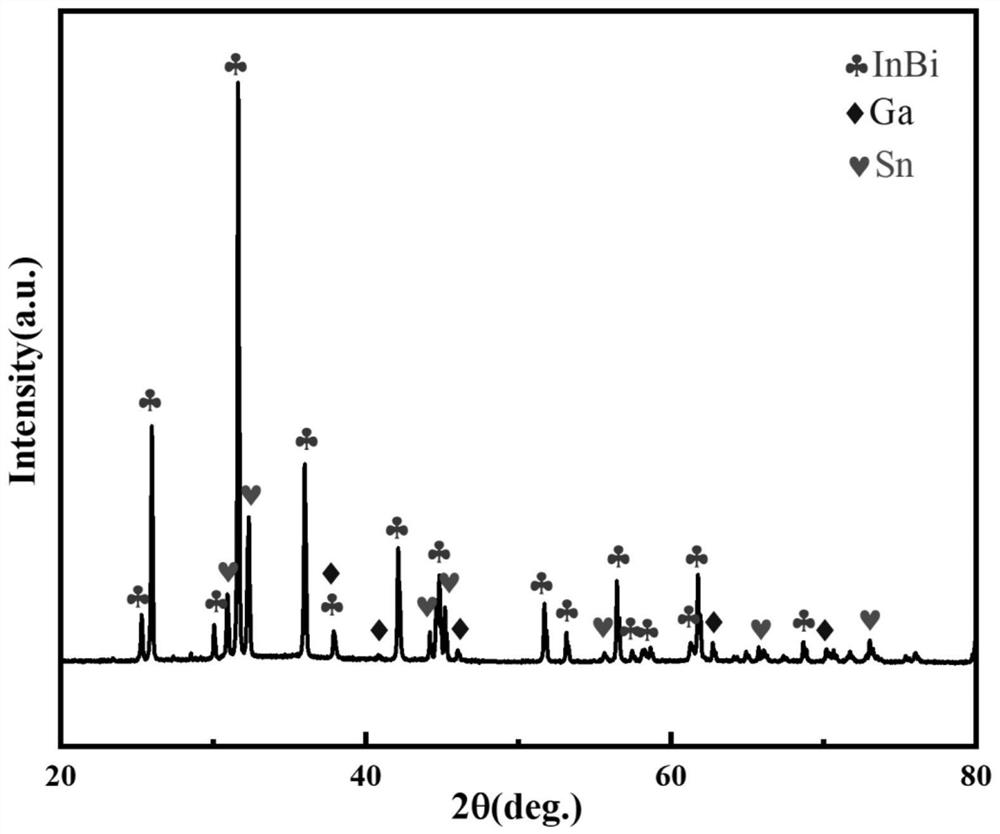

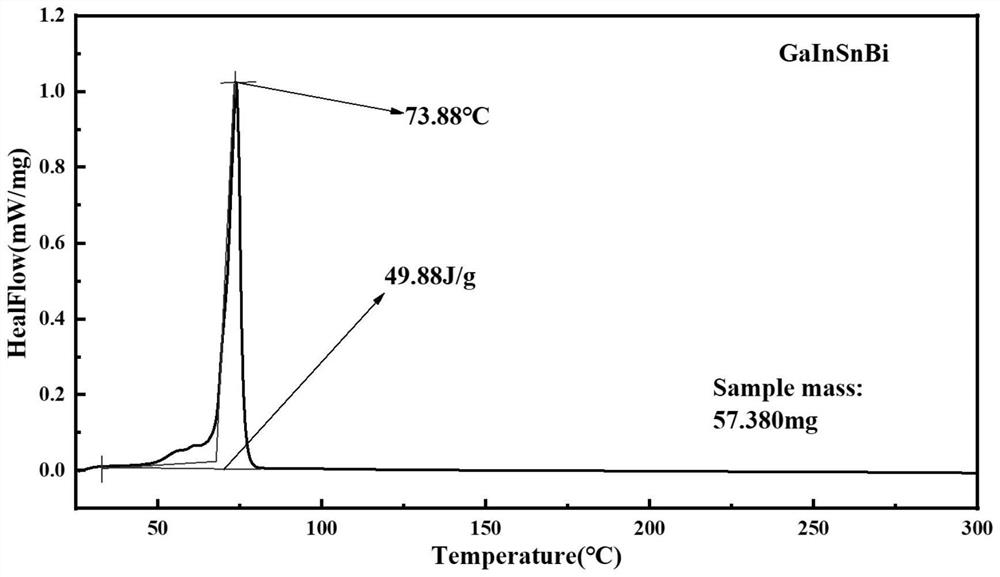

[0032] Embodiment 1: The low melting point alloy phase change material of this embodiment is GaInSnBi system;

[0033] A method for preparing a low melting point alloy phase change material, the specific steps are as follows:

[0034] (1) After polishing the surface of the raw materials Ga, In, Sn and Bi (the purity is 99.99%) with sandpaper, then wash with 5% hydrogen chloride solution to fully remove surface oxides, wash with deionized water and dry to obtain pure substances;

[0035] (2) Add the raw materials Ga, In, Sn and Bi into the melting medium (glycerol), and raise the temperature to a preset temperature of 130°C for 3 hours at a constant speed to alloy the metal to obtain an alloying system; wherein the melting medium glycerol is submerged in the metal raw material for 3cm; The molar fractions of Ga, In, Sn, and Bi are 25%, 25%, 25%, and 25%, respectively, based on the molar weight of alloying elements in the low melting point alloy phase change material being 100%;...

Embodiment 2

[0040] Embodiment 2: The low melting point alloy phase change material in this embodiment is GaInSnBiZn system;

[0041] A method for preparing a low melting point alloy phase change material, the specific steps are as follows:

[0042] (1) After polishing the surface of the raw materials Ga, In, Sn, Bi and Zn (the purity is 99.99%) with sandpaper, then wash with 5% hydrogen chloride solution to fully remove surface oxides, wash with deionized water and dry to obtain pure substances ;

[0043] (2) Add the raw materials Ga, In, Sn, Bi and Zn into the melting medium (methyl silicone oil), raise the temperature at a constant rate to the preset temperature of 200°C and keep it for 5 hours to alloy the metal to obtain an alloying system; the melting medium methyl silicone oil Submerge the metal raw material for 3 cm; take the molar weight of alloying elements in the low melting point alloy phase change material as 100%, and the molar fractions of Ga, In, Sn, Bi and Zn are respecti...

Embodiment 3

[0048] Embodiment 3: The low melting point alloy phase change material in this embodiment is GaInSnBi30Zn10 series;

[0049] A method for preparing a low melting point alloy phase change material, the specific steps are as follows:

[0050] (1) After polishing the surface of the raw materials Ga, In, Sn, Bi and Zn (the purity is 99.99%) with sandpaper, then wash with 5% hydrogen chloride solution to fully remove surface oxides, wash with deionized water and dry to obtain pure substances ;

[0051] (2) Add the raw materials Ga, In, Sn, Bi and Zn into the melting medium (glycerol), and raise the temperature to the preset temperature of 200°C for 5 hours at a constant speed to alloy the metal to obtain an alloying system; wherein the melting medium glycerin is submerged in the metal raw material 2cm; the molar fractions of Ga, In, Sn, Bi, and Zn are respectively 20%, 20%, 20%, 30%, and 10% based on the molar weight of alloying elements in the low-melting point alloy phase change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| latent heat | aaaaa | aaaaa |

| latent heat | aaaaa | aaaaa |

| latent heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com