Polyamide functional master batch carrier resin and polyamide functional master batch

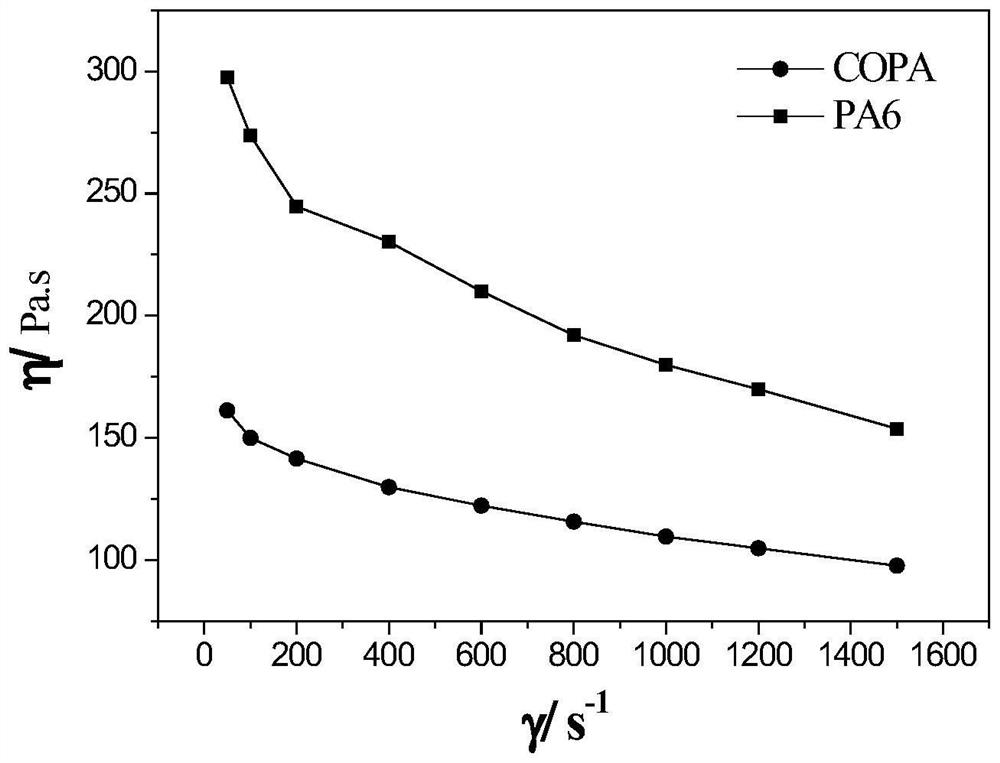

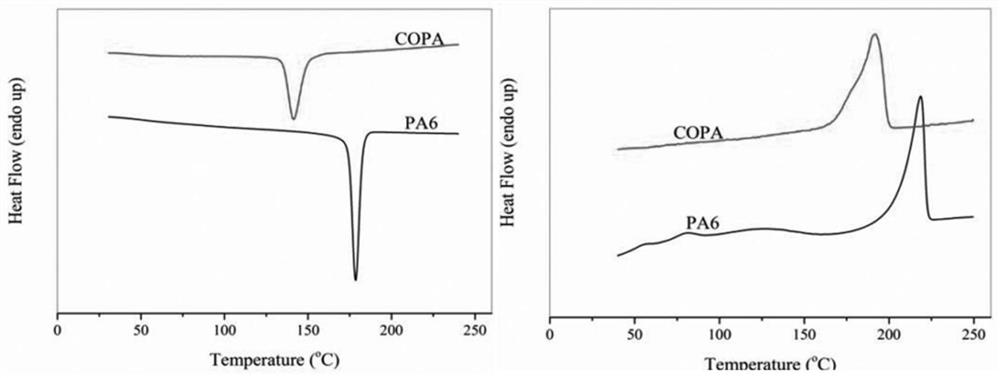

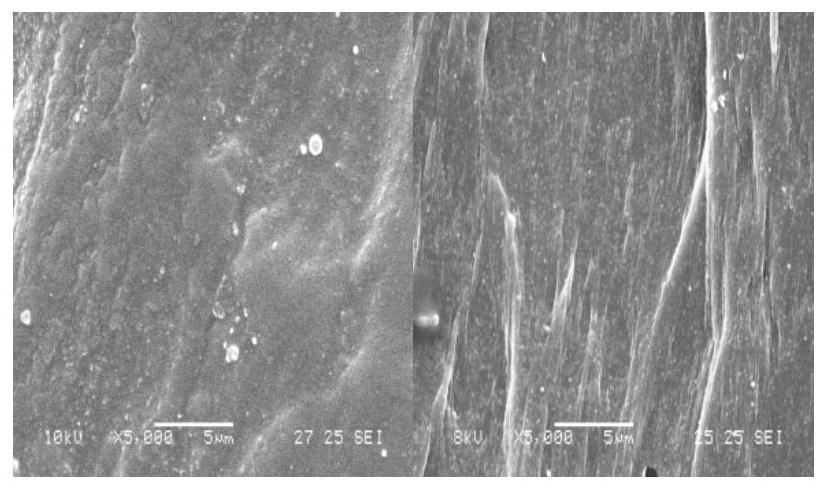

A technology of functional master batch and carrier resin, which is applied in the field of polyamide functional master batch carrier resin and polyamide functional master batch, can solve the problems of poor dispersion uniformity and difficulty in dispersing functional powder, and achieves improved processing performance and accelerated dispersion effect. , the effect of improving liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] As an embodiment of the present invention, the present embodiment provides a polyamide functional masterbatch carrier resin. In this embodiment, the ratio of raw materials (molar ratio) used is as follows:

[0052] caprolactam: 100;

[0053] Nylon 66 salt: 5;

[0054] Branching agent aminocaprolactam: 0.1.

[0055] Further, the preparation method of above-mentioned polyamide functional master batch carrier resin is as follows:

[0056] S1, the raw material is transported to the pre-polymerization reactor for hydrolysis and ring-opening copolymerization to obtain the copolyamide prepolymer, and the reaction temperature is 260° C., and the reaction pressure is 4MPa;

[0057] S2, the copolyamide prepolymer prepared in step S1 is transported to the prepolymerization reactor for prepolymerization reaction to obtain the copolyamide prepolymer, the reaction temperature is 270 ° C, and the reaction pressure is 0.6 MPa;

[0058] S3. The copolyamide prepolymer prepared in step...

Embodiment 2

[0062] As an embodiment of the present invention, the present embodiment provides a polyamide functional masterbatch carrier resin. In this embodiment, the ratio of raw materials (molar ratio) used is as follows:

[0063] caprolactam: 100;

[0064] Nylon 66 salt: 30;

[0065] Branching Agent Lysine: 1.

[0066] Further, the preparation method of above-mentioned polyamide functional master batch carrier resin is as follows:

[0067] S1, the raw material is transported to the pre-polymerization reactor for hydrolysis and ring-opening copolymerization to obtain the copolyamide prepolymer, and the reaction temperature is 260° C., and the reaction pressure is 4MPa;

[0068] S2, the copolyamide prepolymer prepared in step S1 is transported to the prepolymerization reactor for prepolymerization reaction to obtain the copolyamide prepolymer, the reaction temperature is 270 ° C, and the reaction pressure is 0.6 MPa;

[0069] S3. The copolyamide prepolymer prepared in step S2 is tran...

Embodiment 3

[0073] As an embodiment of the present invention, the present embodiment provides a polyamide functional masterbatch carrier resin. In this embodiment, the ratio of raw materials (molar ratio) used is as follows:

[0074] caprolactam: 100;

[0075] Nylon 66 salt: 20;

[0076] Branching agent pyromellitic acid: 0.5.

[0077] Further, the preparation method of above-mentioned polyamide functional master batch carrier resin is as follows:

[0078] S1, the raw material is transported to the pre-polymerization reactor for hydrolysis and ring-opening copolymerization to obtain the copolyamide prepolymer, and the reaction temperature is 260° C., and the reaction pressure is 4MPa;

[0079] S2, the copolyamide prepolymer prepared in step S1 is transported to the prepolymerization reactor for prepolymerization reaction to obtain the copolyamide prepolymer, the reaction temperature is 270 ° C, and the reaction pressure is 0.6 MPa;

[0080] S3. The copolyamide prepolymer prepared in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com