Electrode silver paste for front surface of crystalline silicon solar cell

A technology of solar cells and crystalline silicon, applied in conductive materials, circuits, photovoltaic power generation and other directions dispersed in non-conductive inorganic materials, can solve the problem of incomplete coating of silver powder particles, decreased EL yield of paste, and incomplete coating of silver powder. and other problems, to achieve the effect of improving the selection range, high photoelectric conversion efficiency, and stable EL yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

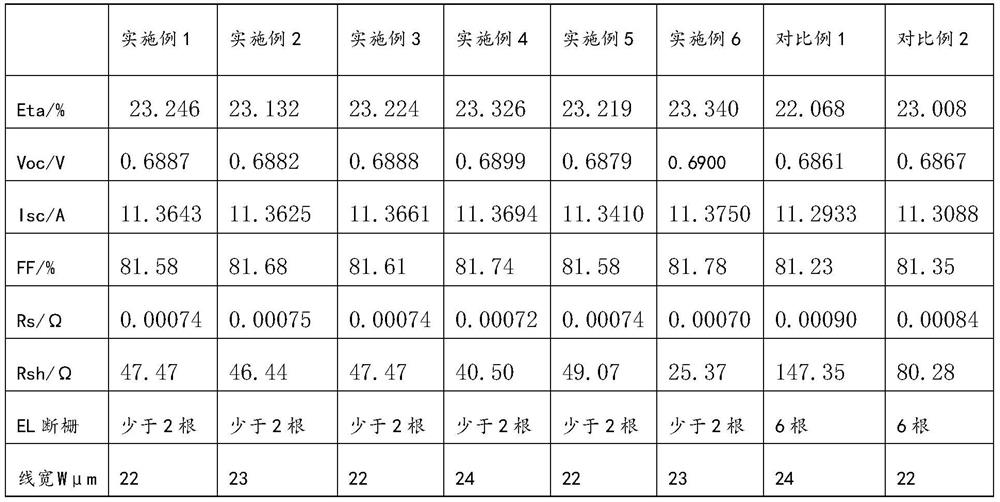

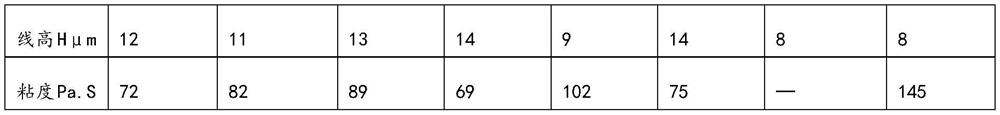

Examples

Embodiment 1

[0056] 1. Resin dissolution:

[0057] Dissolve the acrylic resin in an ethanol solvent (100L), control the concentration of the resin to 0.1%, heat the temperature at 100°C, stir for 60 minutes, and stir at a speed of 2000r / min to obtain the dissolved resin;

[0058] 2. Silver powder package:

[0059] After the resin is fully dissolved, add silver powder to the solution. The ratio of silver powder to resin is 200:1. Set the temperature at 80°C and stir at 2000r / min for 60 minutes. During this process, the resin will fully wrap the surface of the silver powder.

[0060] 3. Resin shaping:

[0061] After the coating is completed, set the temperature at 300°C and continue stirring to volatilize the solvent in the mixture, stir for 40 minutes (when about 80% of the volatilization is completed), and stop stirring. The slurry of silver powder, resin and solvent was placed in a tray, dried in a vacuum oven at 80° C. for 1 hour, and then cooled to room temperature to set the resin. ...

Embodiment 2

[0068] Embodiment 2 (ratio of silver powder and resin)

[0069] 1. Resin dissolution:

[0070] Dissolve the acrylic resin in an ethanol solvent (100L), control the resin concentration to 0.1%, heat at 100°C, stir for 60 minutes, and stir at a speed of 2000r / min to obtain the dissolved resin;

[0071] 2. Silver powder package:

[0072] After the resin is fully dissolved, add silver powder to the solution. The ratio of silver powder to resin is 100:1. Set the temperature at 80°C and stir at 2000r / min for 60 minutes. During this process, the resin will fully wrap the surface of the silver powder.

[0073] 3. Resin shaping:

[0074] After the coating is completed, set the temperature at 300°C and continue stirring to volatilize the solvent in the mixture, stir for 40 minutes (when about 80% of the volatilization is completed), and stop stirring. The slurry of silver powder, resin and solvent was placed in a tray, dried in a vacuum oven at 80° C. for 1 hour, and then cooled to r...

Embodiment 3

[0080] According to the method of Example 1, the difference is only in step 1: dissolving methyl cellulose in alcohol ester twelve solvent (100L), controlling the concentration of resin to 0.1%, heating temperature 100°C, stirring time 60 minutes, stirring speed 2000r / min, obtain the resin of dissolving; Other steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com