Surface modified nanometer material serving as lubricating oil additive as well as preparation method and application thereof

A lubricating oil additive and surface modification technology, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problem of inability to realize the activation and modification of the surface modifier and the powder to be treated, and the burning and deterioration of the organic material of the surface modifier. and damage to achieve the effect of promoting surface treatment and enhancing contact activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

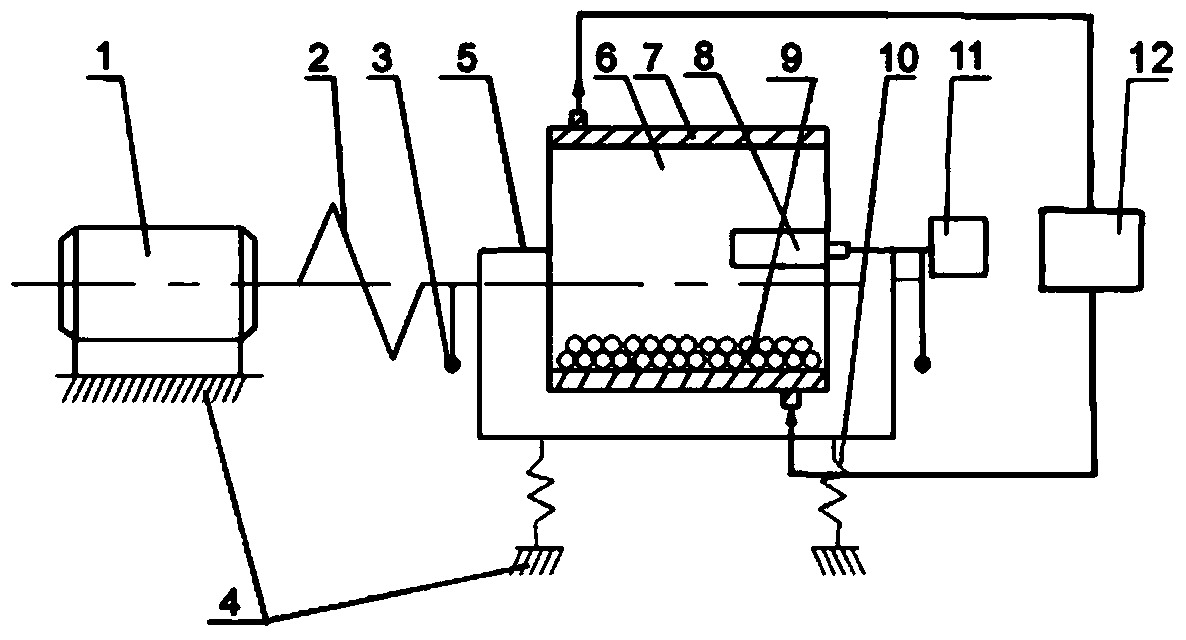

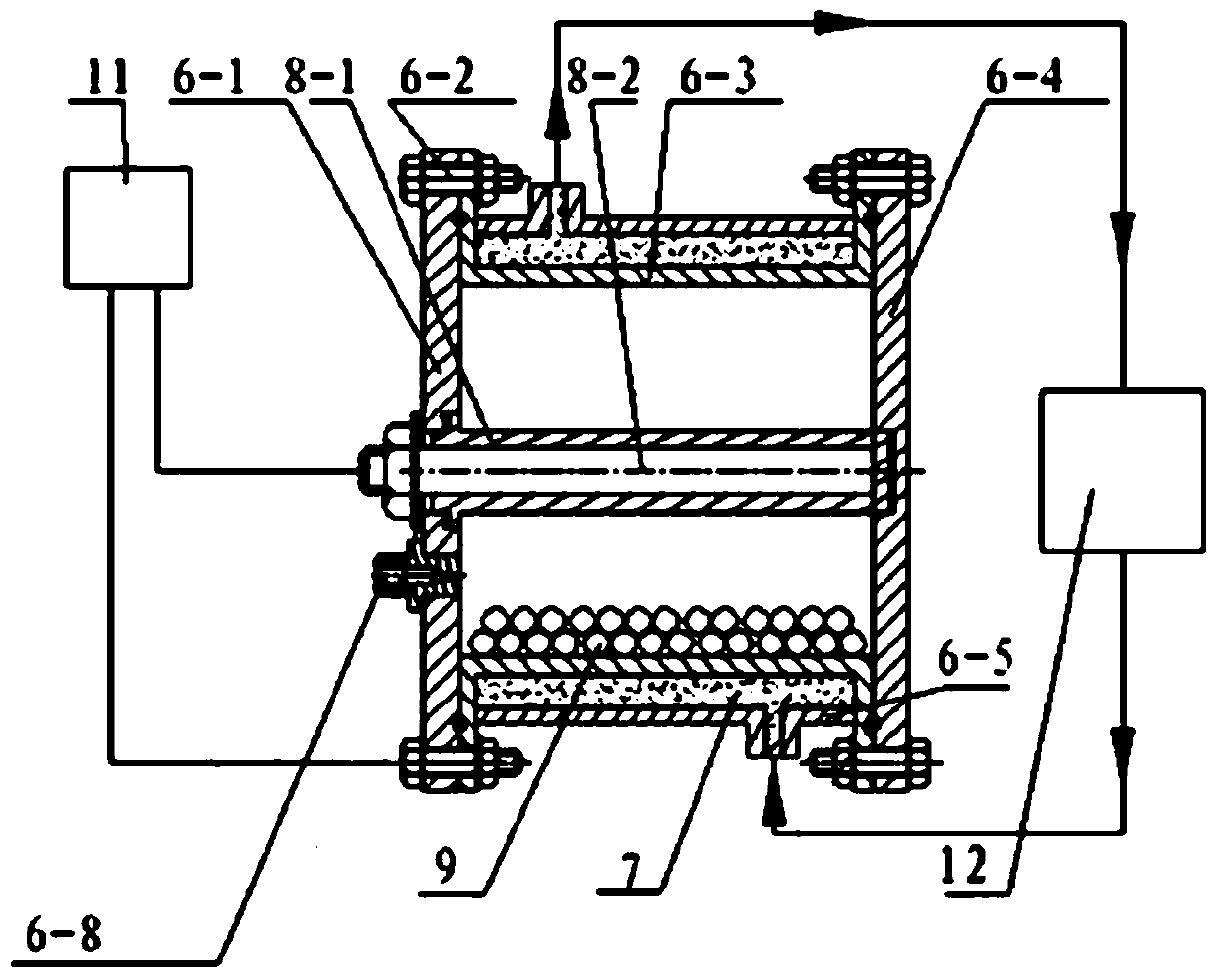

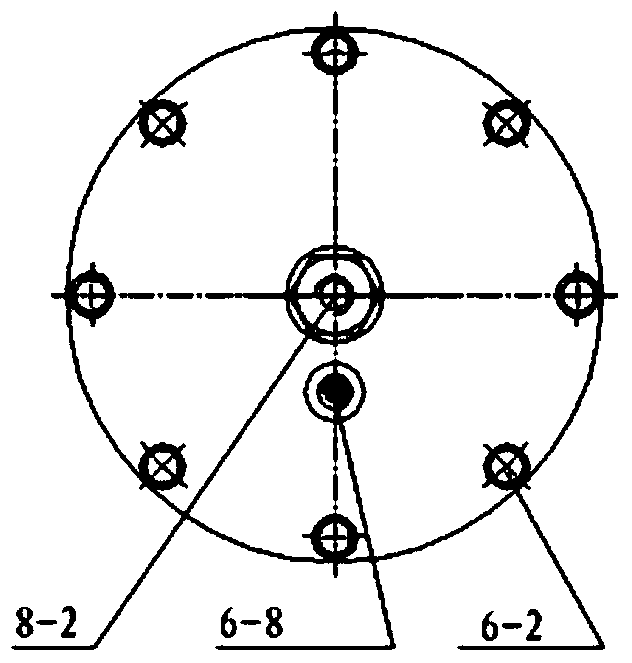

[0059] Such as figure 1 As shown, the dielectric barrier discharge plasma-assisted mechanical ball milling device of the present invention includes a motor 1, an elastic coupling 2, an exciter 3, a base 4, a bracket 5, a ball mill tank 6, a cooling liquid chamber 7, and an electrode rod 8 , Grinding ball 9, spring 10, dielectric barrier discharge power supply 11, constant temperature bath 12. The ball mill pot 6 is seated on the bracket 5. When the motor 1 drives the elastic coupling 2 to rotate, the vibrator 3 rotates, and drives the bracket 5 and the ball mill pot 6 to vibrate on the spring 10. Vibration is generated in the tank 6, so as to perform mechanical impact, shearing and other effects on the powder to be processed in the tank. An electrode rod 8 is installed in the ball mill tank 6, and the dielectric barrier discharge strength in the ball mill tank 6 can be controlled by adjusting the discharge parameter through the dielectric barrier discharge power supply 11, so...

Embodiment 2

[0093] Adopt the device of embodiment 1, process condition is basically identical with embodiment 1, difference is:

[0094] 1. The powder to be treated in step (2) is 500g of TiO 2 , the surface modification agent is the surface modification system that the benzoyl peroxide of 20g and polystyrene form, and wherein the mass ratio of benzoyl peroxide and polystyrene is 1:3;

[0095] 2. In step (5), adjust the discharge parameters as follows: the voltage is 10kV, and the frequency is 20kHz;

[0096] 3. Step (6) Dielectric barrier discharge plasma assisted mechanical ball milling for 5 hours.

[0097] After dielectric barrier discharge plasma-assisted mechanical ball milling, a powdery surface-modified nanomaterial is obtained, which is denoted as P-2a.

Embodiment 3

[0109] Adopt the device of embodiment 1, process condition is basically identical with embodiment 1, difference is:

[0110] 1. The powder to be treated in step (2) is 500g of metal Cu powder, and the surface modifier is 15g of stearic acid;

[0111] 2. In step (3), there is 0.1MPa argon in the ball milling tank 6. The specific operation steps are: evacuate the airtight ball milling tank 6 through the air valve 6-8, and then pass the discharge atmosphere medium through the air valve 6-8 Argon, until the gas pressure in the ball milling tank 6 is 0.1Mpa;

[0112] 3. Step (4) Control the circulating coolant temperature to -20°C;

[0113] 4. In step (5), adjust the discharge parameters as follows: the voltage is 15kV, and the frequency is 22kHz;

[0114] 5. In step (6), the dielectric barrier discharge plasma-assisted mechanical ball milling time is 10 hours;

[0115] After dielectric barrier discharge plasma-assisted mechanical ball milling, a powdery surface-modified nanomat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com