A kind of composite calcium ferrite prepared by using red mud and stainless steel pickling sludge and its preparation method and application

A technology for compounding calcium ferrite and pickling sludge, applied in the field of metallurgy, can solve the problems of high price and high steelmaking cost, and achieve the effects of low production cost, low sulfur content and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

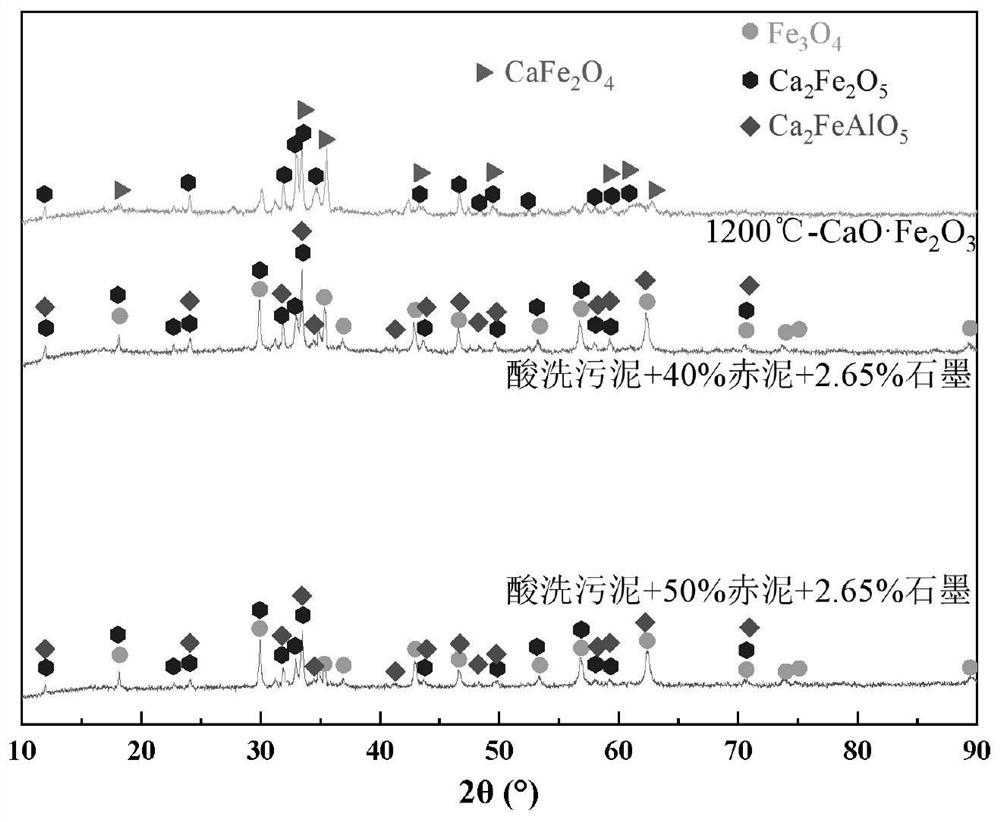

[0041] Grind Bayer red mud, stainless steel pickling sludge and pure graphite powder from a domestic alumina enterprise, and pass through a 200-mesh sieve to take the undersize; according to the total Fe 2 O 3 : CaSO 4 : Calculate the molar ratio of C as 1.6:2:1, weigh 40g of Bayer red mud, 100g of stainless steel pickling sludge and 2.65g of graphite, mix with a mixer for 2 minutes, and press into a cylindrical block of D10mm×H10mm;

[0042] The cylindrical block was placed in a horizontal high temperature resistance furnace, heated to 1150°C at 5°C / min, kept for 4h in a protective atmosphere of Ar gas, and the solid phase was cooled to obtain composite calcium ferrite, including 80% Ca 2 Fe 2 O 4 and 15% Ca 2 FeAlO 5 , the total sulfur content in the product is 0.0169%.

Embodiment 2

[0044] Grind Bayer red mud, stainless steel pickling sludge and pure graphite powder from a domestic alumina enterprise, and pass through a 200-mesh sieve to take the undersize; according to the total Fe 2 O 3 : CaSO 4 Calculate the molar ratio of :C as 2:2:1, weigh 50g of Bayer red mud, 100g of stainless steel pickling sludge and 2.65g of graphite, mix with a mixer for 2 minutes, and press into a cylindrical block of D10mm×H10mm;

[0045] The cylindrical block was placed in a horizontal high temperature resistance furnace, heated to 1150°C at 5°C / min, kept for 3 hours under a protective atmosphere of Ar gas, and the solid phase was cooled to obtain composite calcium ferrite, including 82% Ca 2 Fe 2 O 5 and 12% Ca 2 FeAlO 5 , the total sulfur content in the product is 0.019%, but it has no substantial effect on the subsequent steelmaking desulfurization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com