Bifunctional adsorbent as well as preparation method and application thereof

A dual-function, adsorbent technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of high energy consumption, easily destroying the molecular structure of the adsorbent, complicated steps, etc., to improve the cycle life, The effect of enhancing selective adsorption performance and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

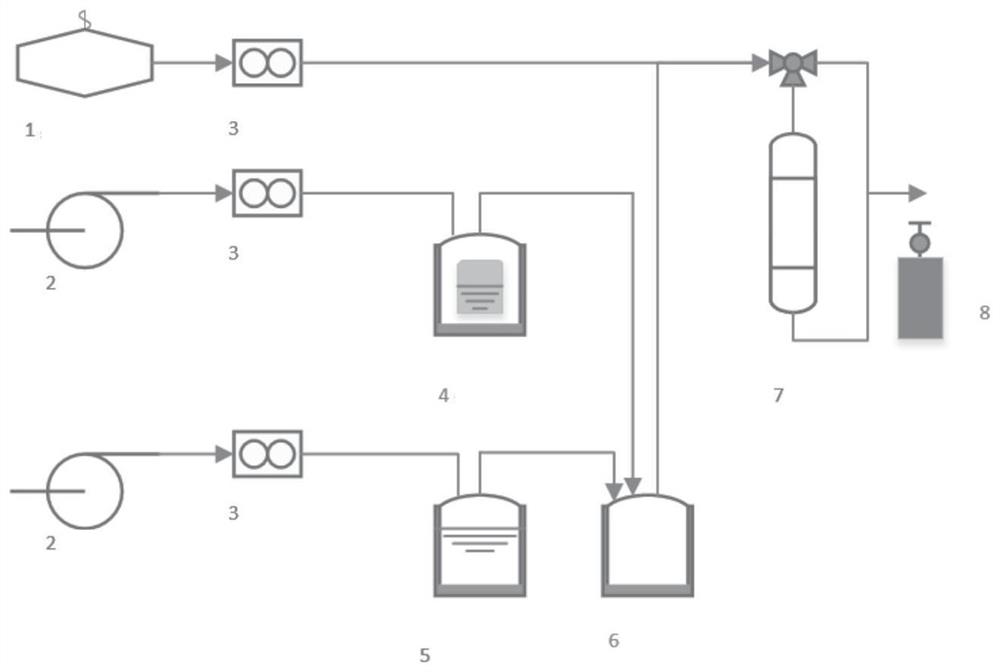

[0025] Specifically, as an aspect of the technical solution of the present invention, the preparation method of a dual-functional adsorbent involves: modifying the cryptomanganite molecular sieve with metal chlorides to obtain a dual-functional adsorbent.

[0026] In some preferred embodiments, the preparation method specifically includes: dissolving the metal chloride in water to form a metal chloride solution, adding cryptopermantite molecular sieves and ultrasonically mixing for 15-30 minutes, then stirring at 30-50°C for 2-4 hours, Afterwards, impregnation treatment is carried out at room temperature for 6-12 hours to obtain the bifunctional adsorbent.

[0027] Further, the content of the metal chloride in the metal chloride solution is 5-12wt%.

[0028] In some preferred embodiments, the metal chloride comprises CuCl 2 、CoCl 2 , FeCl 3 , CeCl 2 , ZnCl 2 Any one or a combination of two or more, and not limited thereto.

[0029] Further, the metal chloride is CuCl 2 ...

Embodiment 1

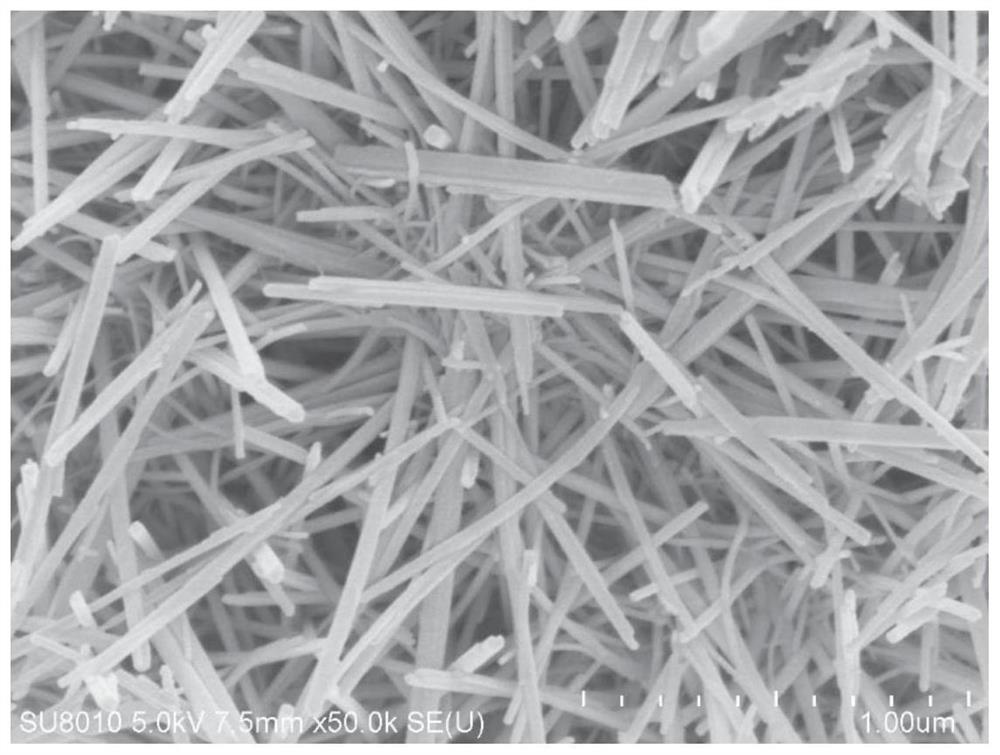

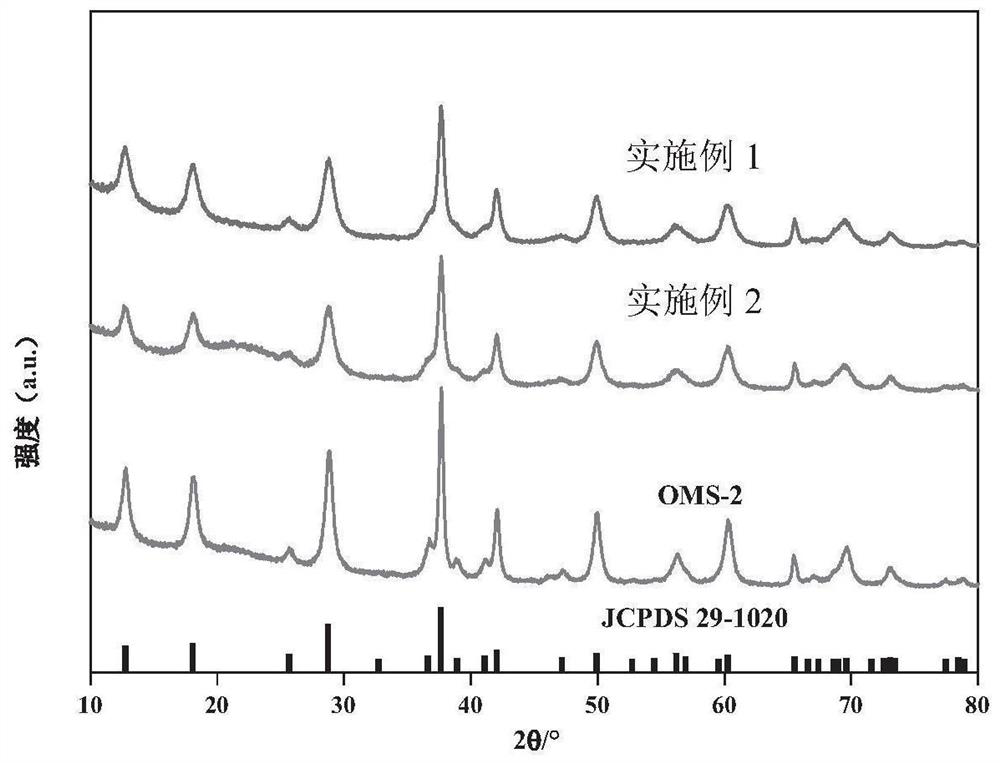

[0053] metal chloride CuCl 2 、CoCl 2 , FeCl 3 , CeCl 2 , ZnCl 2 The mixed solution is configured according to the molar ratio of 1:0.5:0.5:0.2:0, and the mass fraction of the metal chloride in the mixed solution is 5%. Weigh 10g of OMS-2 molecular sieve with a particle size of 20-40 mesh, and add OMS-2 to the above solution, mix ultrasonically for 15min, then stir with a magnetic stirrer for 3h at a temperature of 30°C, and Immerse at room temperature for 6 hours, filter, wash, and dry in an oven at 80°C to obtain a dual-functional adsorbent (microscopic morphology as shown in figure 2 As shown, the XRD diagram is as follows image 3 shown). The resulting bifunctional adsorbent is denoted as C-O-1. Pass the obtained dual-functional adsorbent through the adsorbent performance evaluation device, hydrogen sulfide is used as the evaluation gas, and the inlet H 2 S concentration 300ppm, space velocity 5000h -1 , measure the breakthrough adsorption capacity, and continue t...

Embodiment 2

[0056] metal chloride CuCl 2 、CoCl 2 , FeCl 3 , CeCl 2 , ZnCl 2 The mixed solution is configured according to the molar ratio of 0.5:0.5:0.5:0:0.3, and the mass fraction of the metal chloride in the mixed solution is 12%. Weigh 10g of OMS-2 molecular sieve with a particle size of 20-40 mesh, and add OMS-2 to the above solution, ultrasonically mix for 30min, then stir with a magnetic stirrer for 4h at a temperature of 40°C, and Immerse at room temperature for 12 hours, finally filter, wash, and dry in an oven at 100°C to obtain a dual-functional adsorbent (XRD figure shown in image 3 shown). The resulting bifunctional adsorbent is denoted as C-O-2. The obtained dual-functional adsorption is passed through the adsorbent performance evaluation device, ammonia gas is used as the evaluation gas, and the inlet NH 3 Concentration 300ppm, space velocity 8000h -1 , measure the breakthrough adsorption capacity, and continue to ventilate. When the concentration reaches 50ppm, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com