Preparation method and application of polar group-modified pendent double bond post-crosslinked polydivinylbenzene resin

A polydivinyl benzene, suspended double bond technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem of weak adsorption capacity of polar organic compounds, and achieve obvious selective adsorption , low cost, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

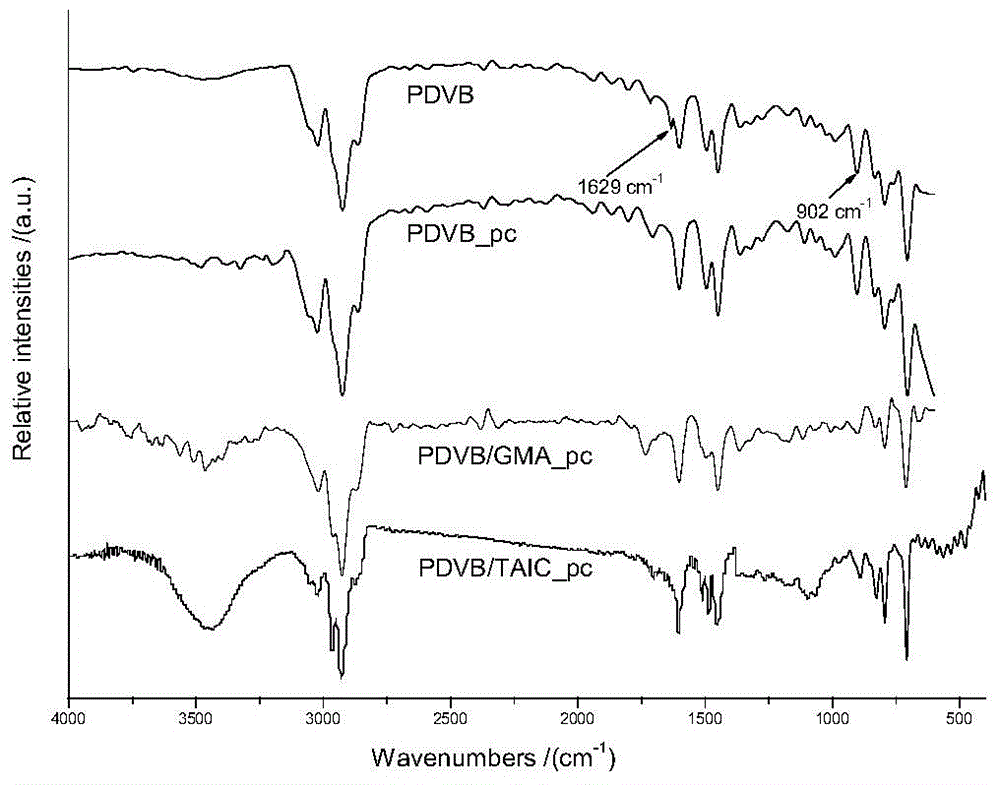

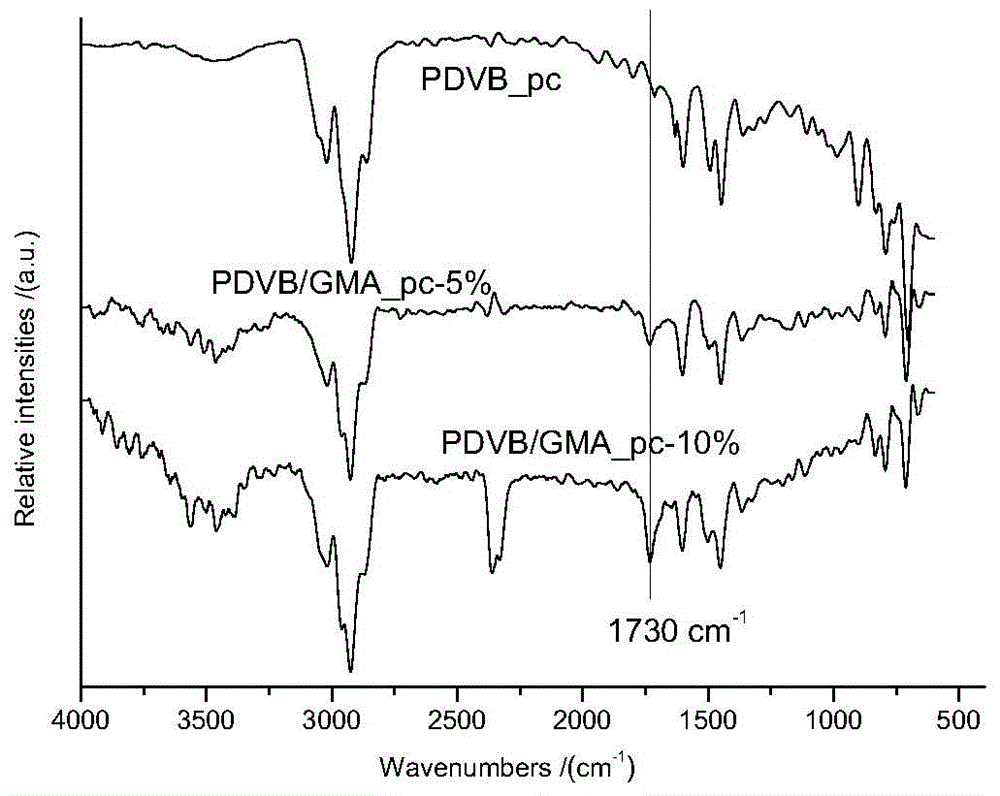

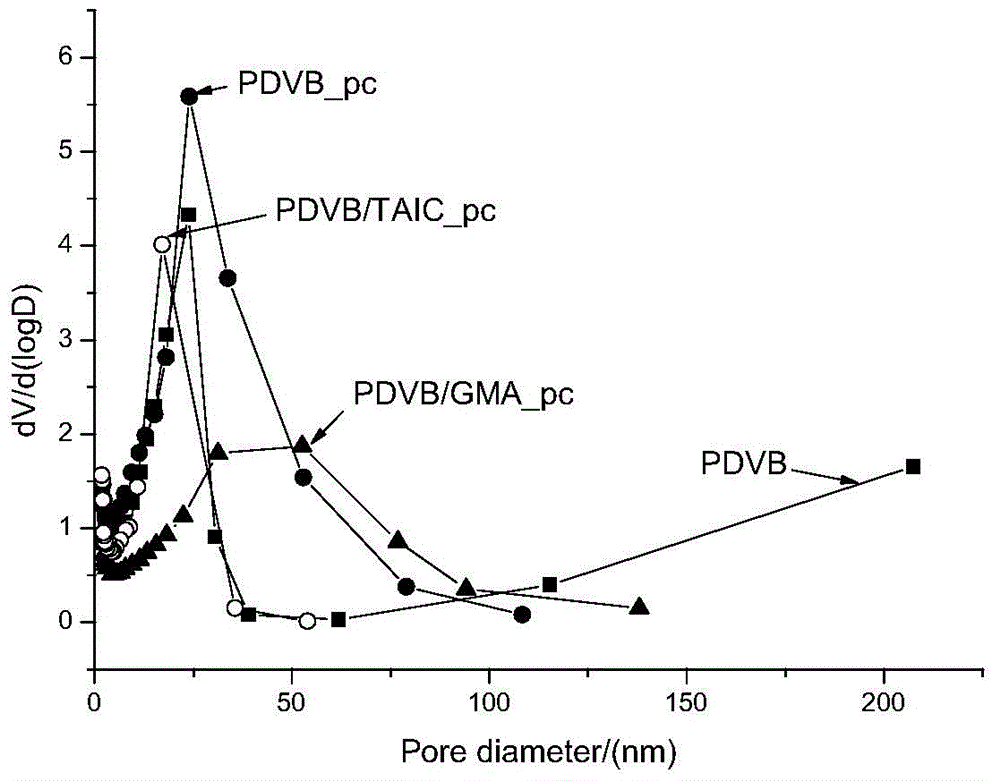

[0034] Preparation of glycidyl methacrylate and divinylbenzene copolymer (PDVB / GMA): add 200mL of 1% PVA aqueous solution to a 500mL three-necked flask equipped with a reflux condenser, a thermometer and a mechanical stirrer, raise the temperature to 45°C, and Add 19g DVB, 1g polar monomer GMA, toluene (mass is 160% of total monomer mass), n-heptane (mass is 40% of total monomer mass) and benzoyl peroxide (mass is mono 1.0% of the total body mass) of the mixed oil phase, adjust the stirring speed to 100r / min, and control the size of the oil droplets. Slowly raise the temperature to 75°C for 2 hours of polymerization; then raise the temperature to 85°C for 3 hours of polymerization; continue to raise the temperature to 95°C and boil the balls for 3 hours. The product was poured out, washed with hot water and cold water respectively, and extracted with petroleum ether for 24 hours to remove the porogen, and dried to obtain the precursor resin PDVB / GMA. The measured average pore...

Embodiment 2

[0038] Preparation of triallyl isocyanurate and divinylbenzene copolymer (PDVB / TAIC): add 200mL of 0.8% PVA aqueous solution to a 500mL three-necked flask equipped with a reflux condenser, a thermometer and a mechanical stirrer, and raise the temperature to 45 ℃, under stirring, add 19g DVB, 1g polar monomer TAIC, toluene (mass is 200% of the total monomer mass), n-heptane (mass is 50% of the total monomer mass) and azoisobutyronitrile ( The mass is 0.5% of the total mass of the monomer) mixed oil phase, and the stirring speed is adjusted to 120r / min to control the size of the oil droplets. Slowly raise the temperature to 70°C for 3 hours; then raise the temperature to 87°C for 4 hours; continue to raise the temperature to 90°C for 3 hours. The product was poured out, washed with hot water and cold water respectively, and extracted with petroleum ether for 24 hours to remove the porogen, and dried to obtain the precursor resin PDVB / TAIC. The measured average pore diameter of ...

Embodiment 3

[0043] Preparation of methyl acrylate and divinylbenzene copolymer (PDVB / MA): add 200mL of 1.2% PVA aqueous solution to a 500mL three-necked flask equipped with a reflux condenser, a thermometer and a mechanical stirrer, raise the temperature to 45°C, and stir Add 19g DVB, 1g polar monomer MA, toluene (the mass is 150% of the total mass of the monomer), n-heptane (the mass is 50% of the total mass of the monomer) and benzoyl peroxide (the mass is 150% of the total mass of the monomer) 0.5% of the total mass) of the mixed oil phase, adjust the stirring speed to 125r / min, and control the size of the oil droplets. Slowly raise the temperature to 68°C for 3 hours of polymerization; then raise the temperature to 83°C for 5 hours of polymerization; continue to raise the temperature to 95°C and boil the balls for 3 hours. The product was poured out, washed with hot water and cold water respectively, and extracted with petroleum ether for 24 hours to remove the porogen, and dried to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com