Process for purifying tetramethylsilane

A technology of tetramethylsilane and methylchlorosilane, which is applied in the field of purification technology of tetramethylsilane, can solve the problems of ineffectiveness of impurities, increase cost, cannot be removed, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0025] 1000g of the low boiler fraction (LBP for short) of the direct synthesis of methylchlorosilane, the LBP is first distilled to separate the fraction with a boiling point ≤ 32°C; the fraction is mixed with 1000g of water, stirred and reacted at 10°C for 30 minutes, The water layer was separated, and the oil layer was repeatedly washed with water until it became neutral; the neutral oil layer was distilled to collect 327g of a fraction (VLBP for short) ≤ 32°C.

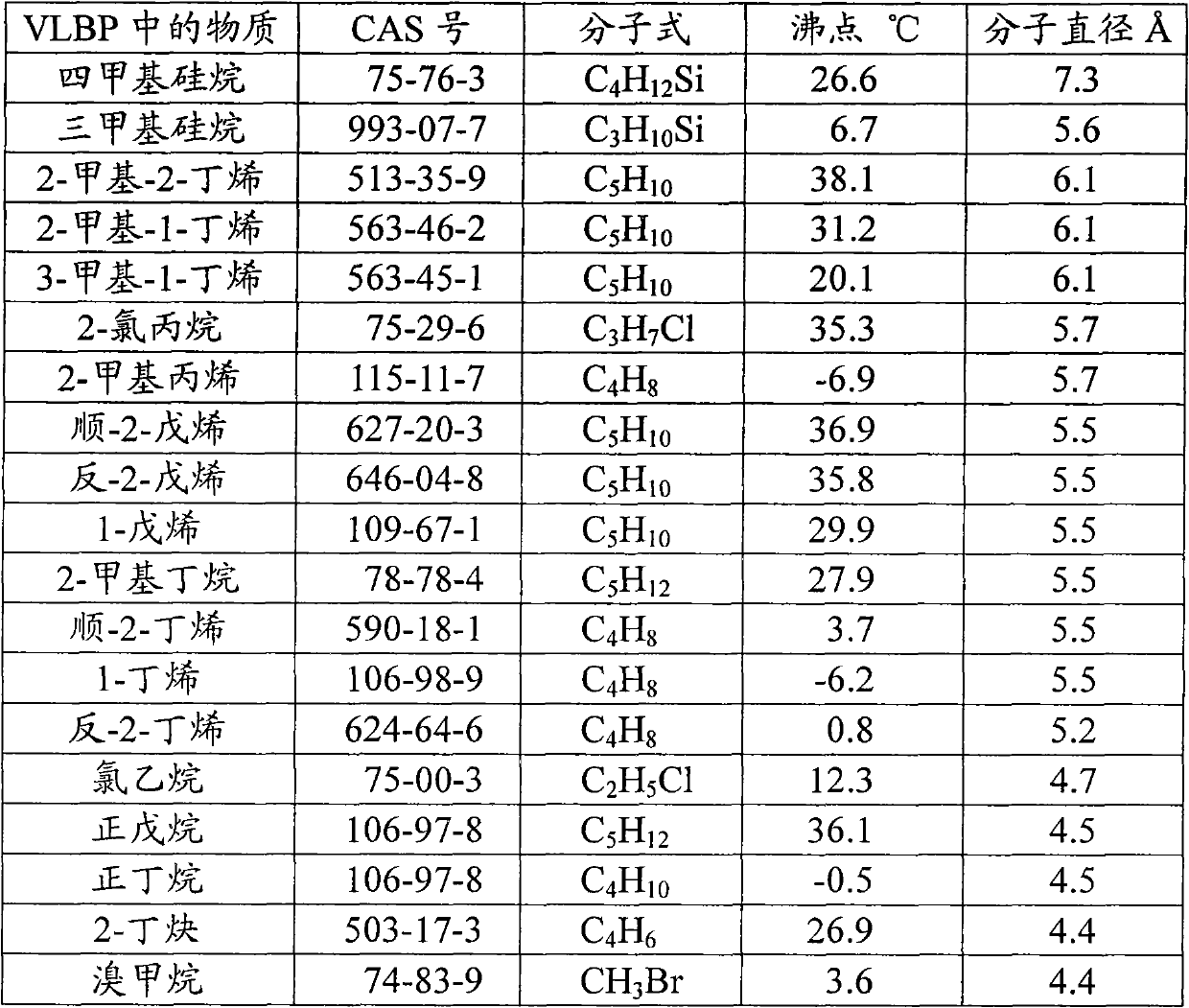

[0026] VLBP was analyzed by a gas chromatograph equipped with an FID detector and a DB-5 capillary column, and the percentage content of the substance in the chromatographic peak area normalized method is shown in Table 2.

[0027] Table 2 Substances and contents in VLBP

[0028]

[0029] A set of adsorption device includes a stainless steel adsorption column with a diameter of 2 cm and a length of 50 cm with an automatic temperature control system. The lower part of the adsorption column is connected to a gasif...

Embodiment 5

[0042] Mix 200g of low boiling fraction (LBP for short) of methyl chlorosilane synthesized by direct method, mix with 200g of water, stir and react at 10°C for 30 minutes, remove the water layer, and wash the oil layer repeatedly with water until neutral; the neutral oil layer is passed through Distill and collect fractions ≤ 38°C (referred to as VLBP).

[0043] VLBP was analyzed by the same gas chromatography as in Example 1, and the percentage content of the chromatographic peak area normalization method of the substance is shown in Table 7.

[0044] Table 7 Substances and contents in VLBP

[0045] Substances in VLBP

[0046] A set of adsorption device includes a stainless steel adsorption column with a diameter of 2cm and a length of 50cm with an automatic temperature control system. The upper part of the adsorption column is connected to the dropping funnel, and the lower part of the adsorption column is an outlet, which is connected to the liquid receiving bottl...

Embodiment 6~7

[0048] The adsorption device of Example 5 is considered as complete adsorption after no liquid flows out, and the molecular sieve is activated and reused. The molecular sieve is activated by purging and activating the adsorption device with nitrogen at 400° C. for 3 hours, and then purging with cold nitrogen to make the temperature of the device reach 25° C. and stop nitrogen. Adjust the automatic temperature control system of the adsorption column to keep the temperature at a constant temperature of 15°C, and put 15 g of VLBP obtained in Example 5 into the dropping funnel; adjust the dropping speed of the dropping funnel so that 15 g of VLBP is added dropwise in about 1 hour, and the adsorption The lower part of the tube collects the adsorption purification sample into the liquid receiving bottle. The purified sample by adsorption was analyzed by the same gas chromatography as in Example 1, and the percentage content of the substances in the chromatographic peak area normaliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com