Method for rapidly removing sediments on back surface of wafer in epitaxial process of silicon carbide

An epitaxial wafer, silicon carbide single crystal technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems affecting the production efficiency of silicon carbide epitaxial wafers, increase manufacturing costs, etc., and achieve cost control and improvement. Production efficiency, effect of reduction in removal process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

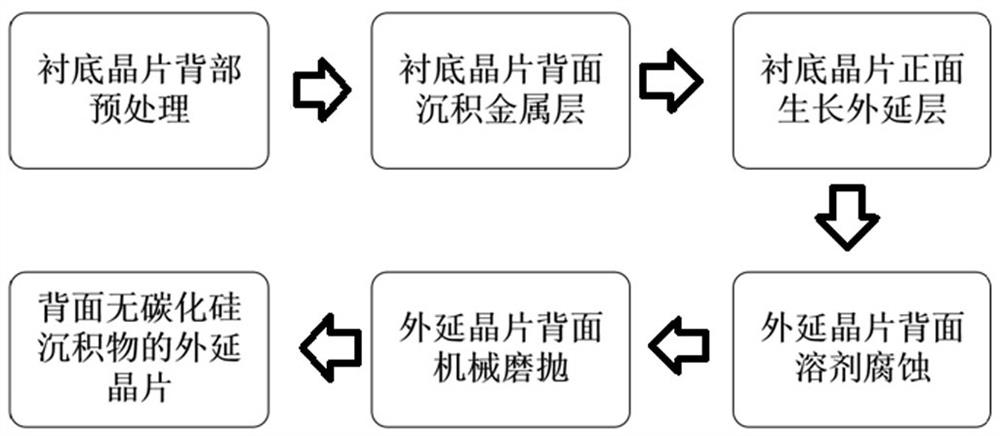

[0025] Embodiment one: if figure 1 Shown, a kind of method that removes the wafer back side deposition in the silicon carbide epitaxy process fast, comprises the following steps:

[0026] S1) Pretreatment of the substrate wafer: the back side (non-epitaxial growth surface) of the silicon carbide single crystal substrate wafer is cleaned, hydrogen etched and / or polished; this step is aimed at cleaning the stains on the back side of the substrate wafer and improve surface flatness; if the incoming quality of the substrate wafer meets the requirements of actual use, the polishing and hydrogen etching processes can be omitted.

[0027] The cleaning of this solution is to use automatic tank cleaning equipment to clean the silicon carbide substrate wafer. The automatic tank cleaning equipment can clean both sides of the substrate wafer at the same time. The cleaning steps are acetone ultrasonic immersion cleaning, sulfuric acid and Hydrogen peroxide mixed solution heating soaking, ...

Embodiment 2

[0035] Embodiment two: if figure 1 Shown, a kind of method that removes the wafer back side deposition in the silicon carbide epitaxy process fast, comprises the following steps:

[0036] S1) Pretreatment of the substrate wafer: cleaning the back of the silicon carbide single crystal substrate wafer; this step aims to clean the stains on the back of the substrate wafer and improve the surface flatness;

[0037] Cleaning is to use automatic tank cleaning equipment to clean the silicon carbide substrate wafer. The automatic tank cleaning equipment can clean both sides of the substrate wafer at the same time. The cleaning steps are acetone ultrasonic immersion cleaning, sulfuric acid and hydrogen peroxide mixed solution Heating soaking, ammonia water and hydrogen peroxide mixed solution heating soaking, deionized water ultrasonic cleaning. The processing time of each step was 20 min, 10 min, 10 min and 20 min in turn.

[0038] S2) Formation of the metal layer: the magnetron spu...

Embodiment 3

[0041] Embodiment three: as figure 1 Shown, a kind of method that removes the wafer back side deposition in the silicon carbide epitaxy process fast, comprises the following steps:

[0042] S1) Substrate wafer pretreatment; the back of the silicon carbide single crystal substrate wafer is cleaned, hydrogen etched and pre-polished; this step aims to clean the stains on the back of the substrate wafer and improve the surface flatness; if the substrate The quality of incoming wafers meets the requirements of actual use, and the polishing and hydrogen etching processes can be omitted.

[0043] Cleaning is to use automatic tank cleaning equipment to clean the silicon carbide substrate wafer. The automatic tank cleaning equipment can clean both sides of the substrate wafer at the same time. The cleaning steps are acetone ultrasonic immersion cleaning, sulfuric acid and hydrogen peroxide mixed solution Heating soaking, ammonia water and hydrogen peroxide mixed solution heating soaki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com