Chemical plating solution for preparing nickel splinter plated diamond abrasive particle, and chemical plating method

A chemical plating solution and diamond technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve problems such as scratches on the workpiece surface, diamond abrasive grain falling off, affecting workpiece quality, etc., and achieve grinding efficiency And the effect of life-enhancement, increased holding power, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

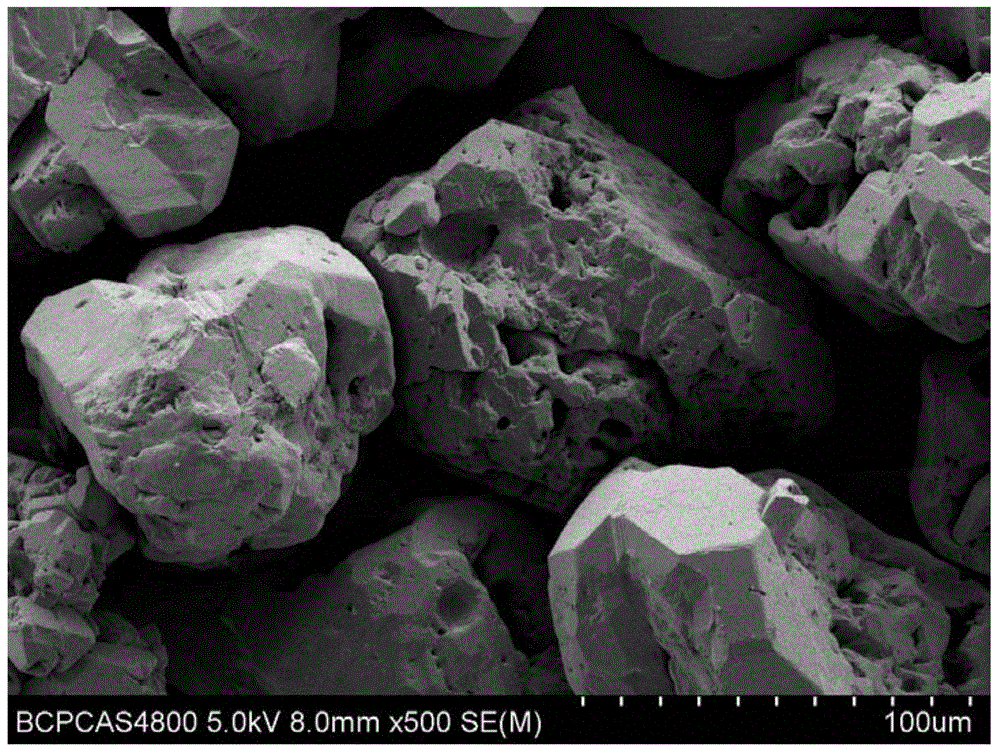

[0065] Example 1: 95 μm nickel-plated thorny diamond abrasive grains

[0066] 1. Take 95μm 1000ct diamond abrasive raw material, pre-sensitization treatment, activation treatment and reduction treatment to obtain reduced diamond, specifically:

[0067] Take 1000ct of 95μm diamond abrasive grains, add 2L of 0.5g / L stannous chloride solution, sensitize for 30min, and wash to obtain sensitized diamond;

[0068] Add 2L of 0.5g / L palladium chloride solution to the sensitized diamond, activate it for 30 minutes, and wash to obtain activated diamond;

[0069] Add 1L of 30g / L sodium hypophosphite solution to the activated diamond, perform reduction treatment for 30min, and wash to obtain reduced diamond;

[0070] 2. Electroless nickel plating stage:

[0071] Prepare the electroless plating solution according to the ratio of Example 1 in Table 1, mix the reduced diamond obtained in step 1 with the 4L configured electroless plating solution to carry out the electroless nickel plating ...

Embodiment 2

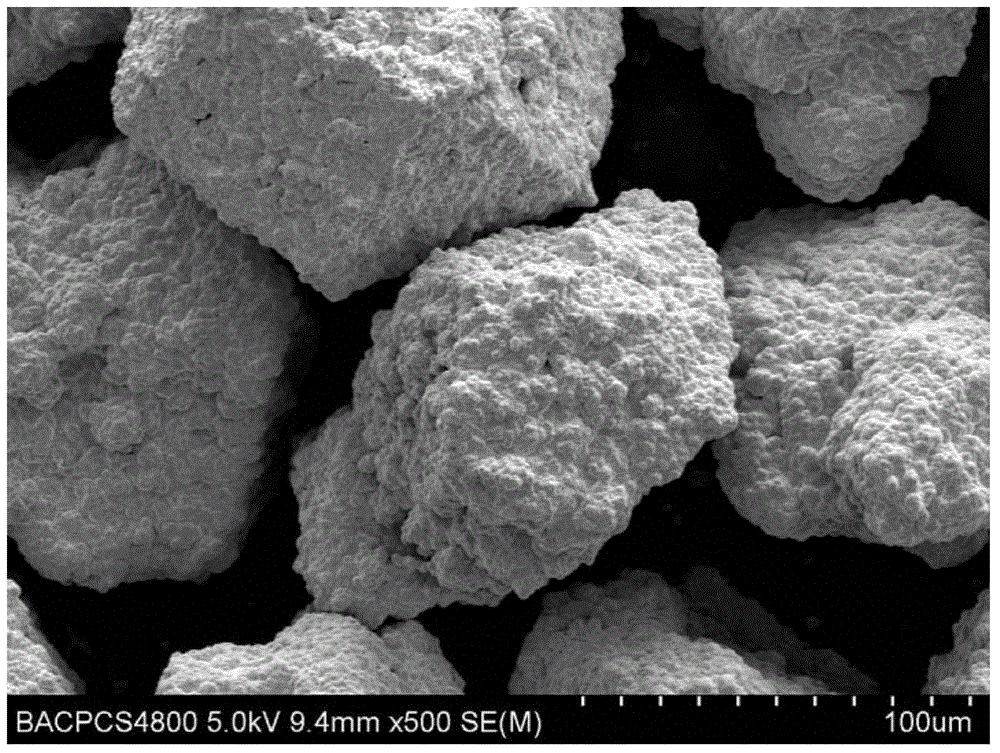

[0085] Example 2: 45 μm nickel-plated thorny diamond abrasive grains

[0086] 1. Pre-sensitization treatment, activation treatment and reduction treatment of 1000ct diamond abrasive raw materials of 45 μm are taken to obtain reduced diamond, which specifically includes the following steps:

[0087] Sensitization treatment: Take 1000ct of diamond abrasive grains with a particle size of 45μm, add 2L of 0.5g / L stannous chloride solution, perform sensitization treatment for 30min, and wash to obtain sensitized diamond;

[0088] Activation treatment: Add 2L of 0.5g / L palladium chloride solution to the sensitized diamond obtained in step 1, activate it for 30 minutes, and wash to obtain activated diamond;

[0089] Reduction treatment: Add 2 L of 30 g / L sodium hypophosphite solution to the activated diamond obtained in step 2, perform reduction treatment for 30 minutes, and wash to obtain reduced diamond;

[0090] 2. Prepare the electroless plating solution according to the ratio of...

Embodiment 3

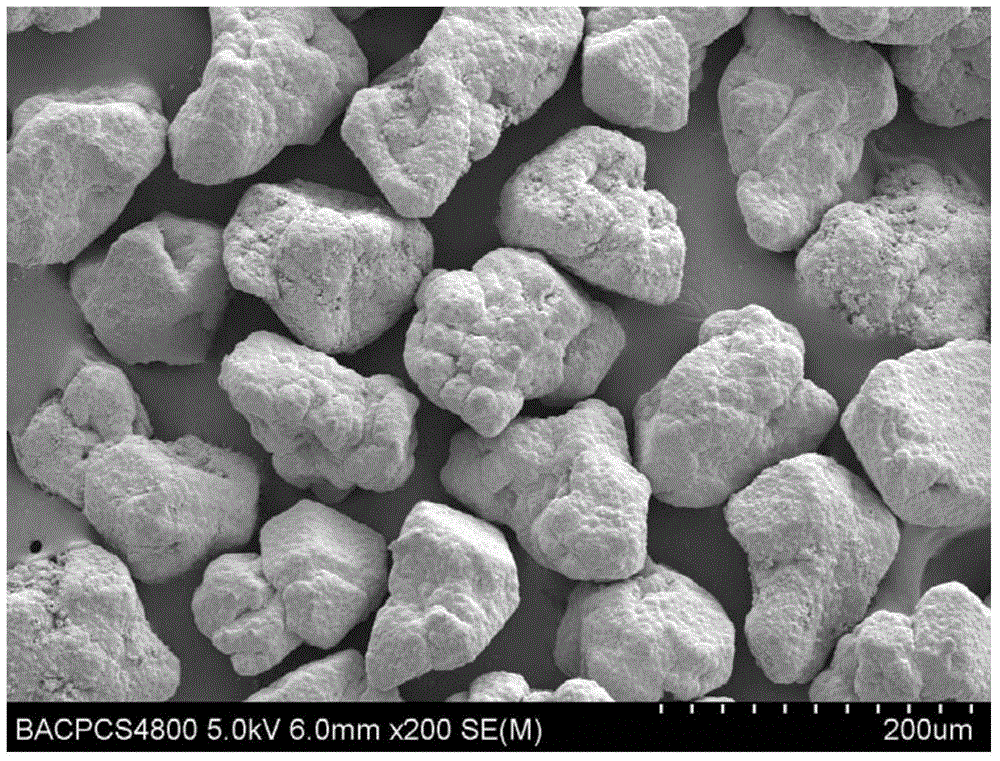

[0095] Example 3: 60 μm nickel-plated thorny diamond abrasive grains

[0096] 1. Pre-sensitization treatment, activation treatment and reduction treatment of 1000ct diamond abrasive raw materials are taken to obtain reduced diamonds, including the following steps:

[0097] Take 1000ct of diamond abrasive raw material with a particle size of 60 μm, add 1L of 1.5g / L stannous chloride solution, perform sensitization treatment for 40min, and wash to obtain sensitized diamond;

[0098] Add 1L of 1.5g / L palladium chloride solution to the sensitized diamond, activate it for 40 minutes, and wash to obtain activated diamond;

[0099] Add 1L of 30g / L sodium hypophosphite solution to the activated diamond, perform reduction treatment for 40min, and wash to obtain reduced diamond;

[0100] 2. Prepare the electroless plating solution according to the ratio of Example 3 in Table 1, mix the reduced diamond obtained in step 1 with 4L of the prepared electroless plating solution to carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com