PT-loaded Ni0.8Fe0.2/Niooh/Feooh mixed crystal composite electrode and preparation method thereof

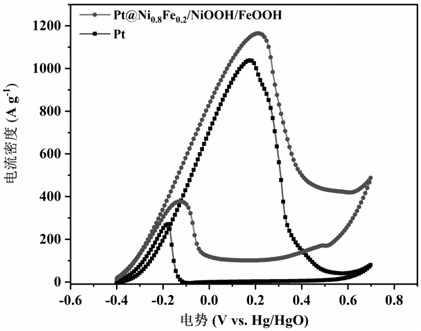

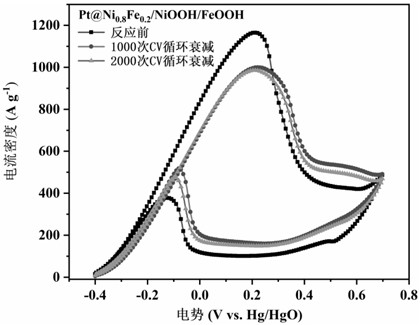

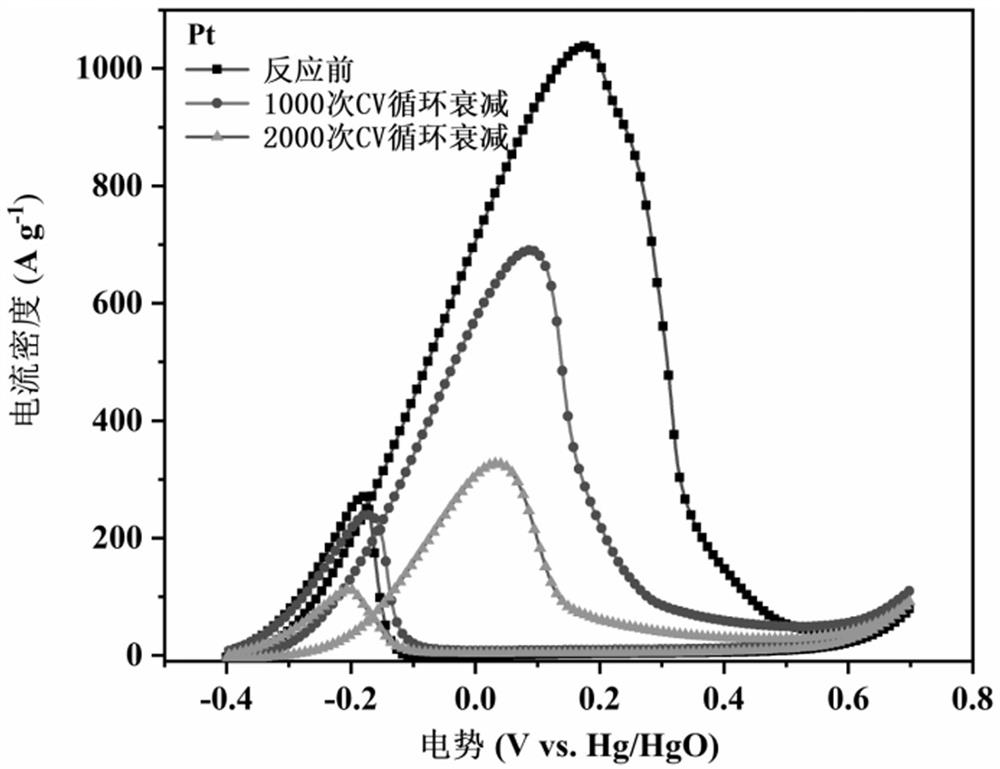

A ni0.8fe0.2, composite electrode technology, used in battery electrodes, circuits, fuel cells, etc., can solve problems such as poor durability, and achieve the effects of good durability, poor durability, excellent activity and long-term durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A Pt-loaded Ni0.8Fe0.2 / NiOOH / FeOOH mixed crystal composite electrode, and its preparation method comprises the following steps:

[0032] (1) The glassy carbon sheet was ultrasonically washed for 3 minutes, then placed in 0.05g of alumina powder for mechanical polishing, and then placed in the washing solution for ultrasonic washing again to remove the surface alumina powder and surface static electricity, and vacuum-dried to obtain pretreated glassy carbon sheet; the washing solution includes absolute ethanol and deionized water, and the volume ratio of absolute ethanol and deionized water is 10:20;

[0033] (2) Fix the pretreated glassy carbon sheet obtained in step (1) on the sample stage of the pulsed laser deposition system, fix the nickel-iron alloy target on the rotating target stage, the pulse width of the laser source is 4ns, the laser repetition frequency is 5Hz, and the pulse Laser deposition for 20 minutes to obtain a glassy carbon sheet loaded with a nickel-...

Embodiment 2

[0037] A Pt-loaded Ni0.8Fe0.2 / NiOOH / FeOOH mixed crystal composite electrode, and its preparation method comprises the following steps:

[0038] (1) The glassy carbon sheet was ultrasonically washed for 5 minutes, then placed in 0.05g of alumina powder for mechanical polishing, and then placed in the washing solution for ultrasonic washing again to remove the surface alumina powder and surface static electricity, and vacuum-dried to obtain pretreated glassy carbon sheet; the washing solution includes absolute ethanol and deionized water, and the volume ratio of absolute ethanol and deionized water is 10:30;

[0039](2) Fix the pretreated glassy carbon sheet obtained in step (1) on the sample stage of the pulsed laser deposition system, and fix the nickel-iron alloy target on the rotating target stage. The pulse width of the laser light source is 5 ns, and the laser repetition frequency is 10 Hz. Laser deposition for 35 minutes to obtain a glassy carbon sheet loaded with a nicke...

Embodiment 3

[0043] A Pt-loaded Ni0.8Fe0.2 / NiOOH / FeOOH mixed crystal composite electrode, and its preparation method comprises the following steps:

[0044] (1) The glassy carbon sheet was ultrasonically washed for 7 minutes, then placed in 0.05g of alumina powder for mechanical polishing, and then placed in the washing solution for ultrasonic washing again to remove the surface alumina powder and surface static electricity, and vacuum-dried to obtain pretreated glassy carbon sheet; the washing liquid comprises absolute ethanol and deionized water, and the volume ratio of absolute ethanol and deionized water is 10:40;

[0045] (2) Fix the pretreated glassy carbon sheet obtained in step (1) on the sample stage of the pulsed laser deposition system, and fix the nickel-iron alloy target on the rotating target stage. The pulse width of the laser source is 6 ns, and the laser repetition frequency is 15 Hz. Laser deposition for 50 minutes to obtain a glassy carbon sheet loaded with a nickel-iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com