Carbon fiber reinforced aluminum alloy layer pipe component forming process and forming mold

A technology of aluminum alloy layer and forming process, which is applied in the field of pipe component forming, can solve the problems of fiber metal secondary processing difficulties and limited use scenarios, and achieve the effects of solving secondary processing difficulties, expanding the application range, and reducing product investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

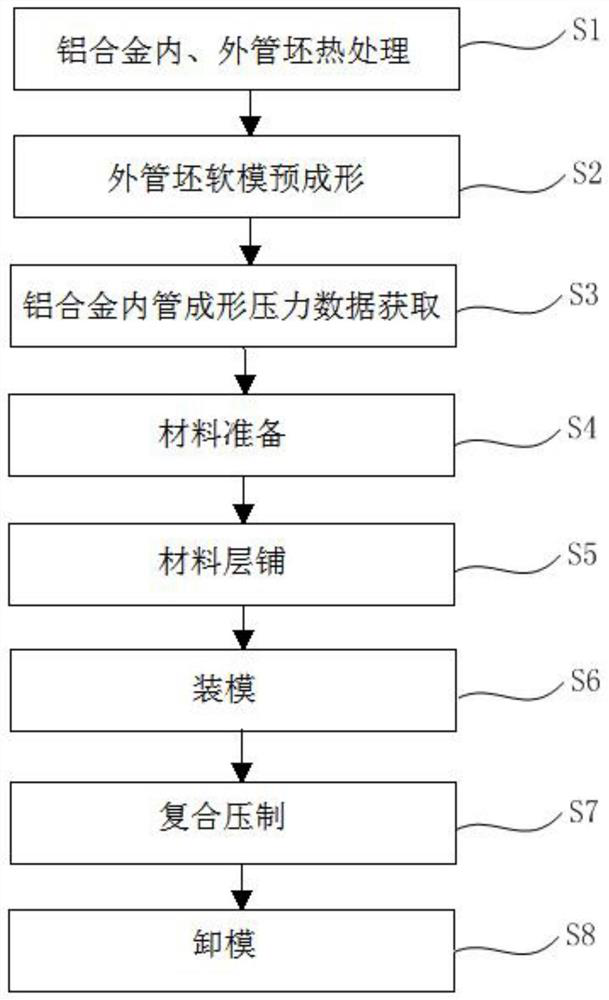

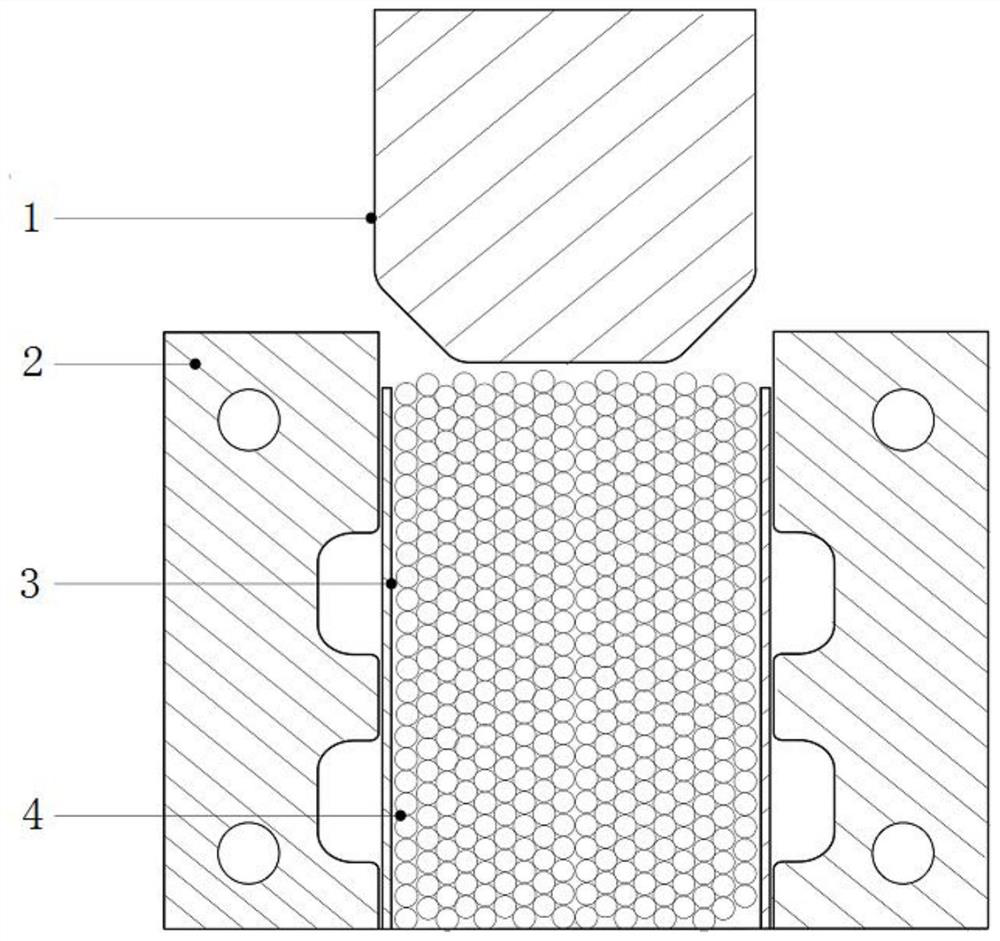

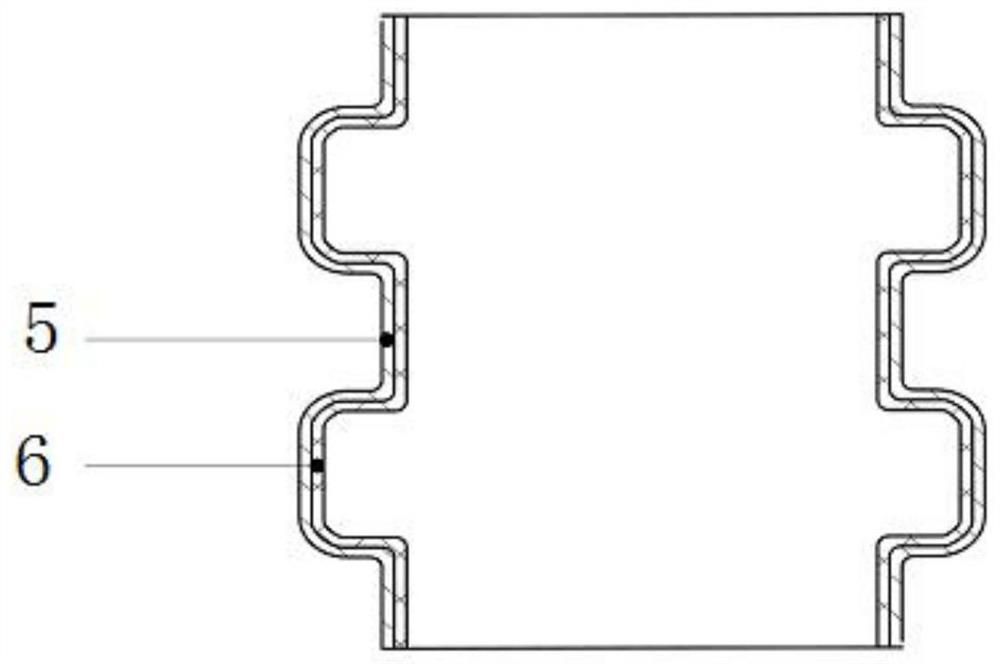

[0057] Such as Figure 1-5 As shown, this embodiment provides a carbon fiber reinforced aluminum alloy layer tube component forming process, which specifically includes the following process route:

[0058] S1) Heat treatment of the aluminum alloy outer tube blank 3 and the aluminum alloy inner tube blank 6: the aluminum alloy outer tube blank 3 and the aluminum alloy inner tube blank 3 can be treated according to the heat treatment process parameters of a solution temperature of 450°C-560°C and a solution time of 15min-120min. The tube blank 6 is subjected to solid solution water quenching to increase the elongation of the plate and reduce the deformation resistance. In this embodiment, the aluminum alloy outer pipe blank 3 and the aluminum alloy inner pipe blank 6 can preferably be made of 6-series aluminum alloy.

[0059] S2) Perform soft mold preforming on the aluminum alloy outer tube blank 3 after heat treatment: place the aluminum alloy outer tube blank 3 in the cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com